Reverse osmosis and nanofiltration are advanced water purification technologies that effectively remove contaminants but differ in filtration mechanisms and pore size. Reverse osmosis uses a semipermeable membrane to eliminate nearly all dissolved solids, including salts and heavy metals, making it ideal for desalination and producing ultrapure water. Nanofiltration membranes have larger pores, allowing selective removal of multivalent ions and organic molecules while retaining beneficial minerals, which is advantageous for softening water and reducing organic content.

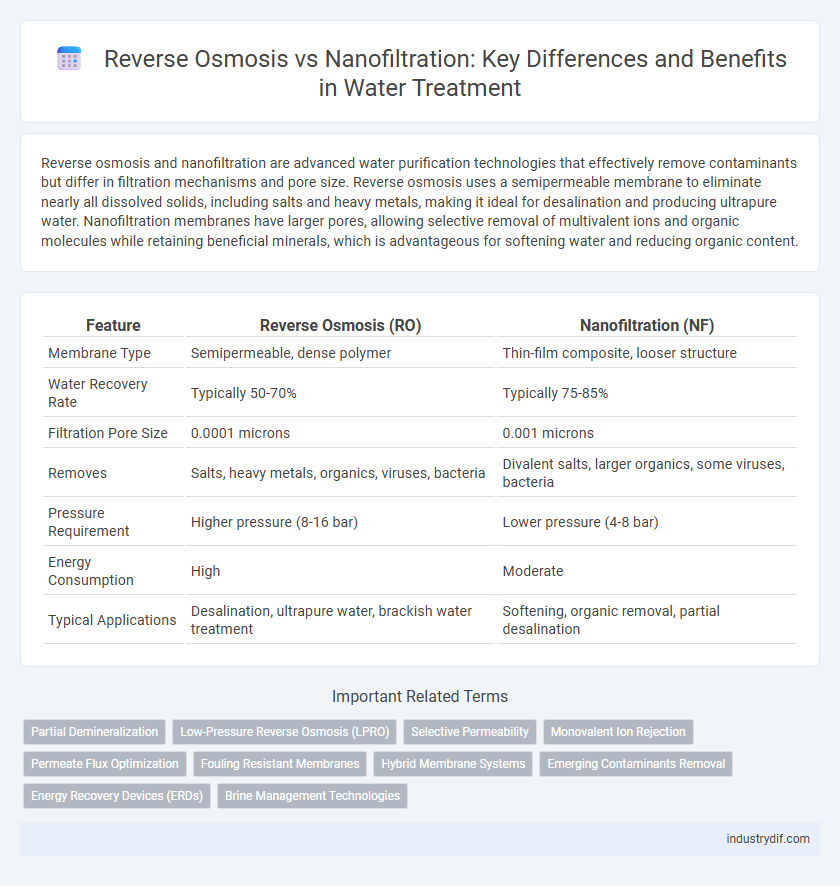

Table of Comparison

| Feature | Reverse Osmosis (RO) | Nanofiltration (NF) |

|---|---|---|

| Membrane Type | Semipermeable, dense polymer | Thin-film composite, looser structure |

| Water Recovery Rate | Typically 50-70% | Typically 75-85% |

| Filtration Pore Size | 0.0001 microns | 0.001 microns |

| Removes | Salts, heavy metals, organics, viruses, bacteria | Divalent salts, larger organics, some viruses, bacteria |

| Pressure Requirement | Higher pressure (8-16 bar) | Lower pressure (4-8 bar) |

| Energy Consumption | High | Moderate |

| Typical Applications | Desalination, ultrapure water, brackish water treatment | Softening, organic removal, partial desalination |

Introduction to Membrane Filtration Technologies

Reverse osmosis and nanofiltration are advanced membrane filtration technologies designed to remove contaminants from water. Reverse osmosis membranes have pore sizes around 0.0001 microns, enabling the removal of nearly all dissolved salts, organic molecules, and microorganisms, making it highly effective for desalination and ultrapure water production. Nanofiltration membranes feature slightly larger pores, approximately 0.001 microns, allowing selective separation of divalent and larger monovalent ions while retaining essential minerals, commonly used for water softening and partial contaminant removal.

Principles of Reverse Osmosis (RO)

Reverse osmosis (RO) operates by applying pressure to force water through a semipermeable membrane, effectively removing contaminants such as salts, bacteria, and organic molecules. This membrane allows only water molecules to pass while rejecting dissolved solids and impurities based on size and molecular weight. RO systems achieve high purification rates, making them ideal for desalination, industrial wastewater treatment, and potable water production.

Fundamentals of Nanofiltration (NF)

Nanofiltration (NF) operates through semi-permeable membranes with pore sizes ranging from 1 to 10 nanometers, targeting the removal of divalent and larger monovalent ions, organic molecules, and pathogens. Unlike reverse osmosis (RO), NF membranes allow partial passage of monovalent salts like sodium and chloride, maintaining essential minerals in treated water while reducing hardness and organic content. The process relies on size exclusion and charge effects, making NF energy-efficient for water softening, color removal, and selective contaminant separation.

Key Differences Between RO and NF

Reverse osmosis (RO) uses a semipermeable membrane with pore sizes around 0.0001 microns, effectively removing nearly all dissolved salts, organic molecules, and microbes, achieving up to 99% salt rejection. Nanofiltration (NF) membranes have larger pores, approximately 0.001 microns, selectively rejecting divalent and larger monovalent ions while allowing partial passage of smaller monovalent ions like sodium and chloride. RO systems require higher operating pressures, typically 8-15 bar, compared to NF's lower pressure range of 4-6 bar, making NF more energy-efficient but less comprehensive in contaminant removal.

Water Purity Levels: RO vs Nanofiltration

Reverse osmosis (RO) systems achieve higher water purity levels by removing up to 99% of dissolved salts, heavy metals, and organic contaminants, making it ideal for applications requiring near-complete desalination. Nanofiltration (NF) membranes retain larger molecules and divalent ions, allowing partial mineral retention and effective removal of microorganisms and certain organic compounds. Water treated with reverse osmosis typically exhibits lower total dissolved solids (TDS) compared to nanofiltration, resulting in purer and softer water suitable for sensitive industrial and drinking purposes.

Typical Applications in Water Treatment

Reverse osmosis (RO) is extensively used for desalination, wastewater recycling, and producing ultrapure water due to its ability to remove up to 99% of dissolved salts, organic compounds, and microorganisms. Nanofiltration (NF) is preferred for softening hard water, removing natural organic matter, and selectively rejecting divalent and larger monovalent ions while allowing smaller ions like sodium and chloride to pass. Both technologies are critical in municipal water treatment, industrial process water purification, and pretreatment for membrane bioreactors.

Energy Consumption and Operational Costs

Reverse osmosis systems typically consume more energy and have higher operational costs due to their need for high-pressure pumps to force water through fine membranes, achieving a 95-99% rejection rate of contaminants. Nanofiltration requires lower pressure, resulting in reduced energy consumption and decreased maintenance expenses, making it more cost-effective for applications targeting divalent ions and organic matter removal. The choice between these technologies depends on the water quality goals and budget constraints linked to energy efficiency and operational sustainability.

Membrane Lifespan and Maintenance Requirements

Reverse osmosis membranes typically have a lifespan of 2 to 5 years, depending on water quality and maintenance frequency, while nanofiltration membranes generally last 3 to 7 years due to their looser pore structure that reduces fouling. Maintenance requirements for reverse osmosis systems involve regular cleaning and pre-treatment to prevent scaling and biofouling, whereas nanofiltration membranes require less intensive chemical cleaning and are more tolerant to water with higher organic content. Both technologies benefit from routine monitoring, but nanofiltration systems often incur lower operational costs related to membrane replacement and cleaning chemicals.

Selection Criteria: When to Use RO or NF

Reverse osmosis (RO) is ideal for producing ultrapure water by removing nearly all dissolved solids, heavy metals, and contaminants, making it suitable for applications requiring high water purity such as pharmaceutical manufacturing or desalination. Nanofiltration (NF) is preferred when partial softening or selective removal of divalent and larger molecules is needed, commonly used in water treatment for agricultural irrigation or wastewater reuse where retaining beneficial minerals is important. Selection criteria depend on target water quality, contaminant types, operating costs, and energy consumption, with RO generally demanding higher energy and maintenance compared to NF systems.

Future Trends in Membrane Filtration Technology

Emerging trends in membrane filtration technology focus on enhancing the efficiency and selectivity of reverse osmosis (RO) and nanofiltration (NF) membranes through advanced materials like graphene oxide and bio-inspired polymers. Integration of AI-driven process optimization and energy recovery systems is expected to significantly reduce operational costs and environmental impact in water purification systems. Future developments aim to tailor membrane pore size and surface chemistry for specific contaminants, enabling more sustainable and scalable solutions in desalination and wastewater treatment.

Related Important Terms

Partial Demineralization

Reverse osmosis achieves near-complete demineralization by removing up to 99% of dissolved salts, making it ideal for applications requiring highly purified water. Nanofiltration provides partial demineralization by selectively removing divalent and larger ions while allowing some monovalent ions to pass, balancing mineral retention with contaminant reduction.

Low-Pressure Reverse Osmosis (LPRO)

Low-Pressure Reverse Osmosis (LPRO) operates at pressures between 4 to 8 bar, offering energy-efficient removal of dissolved salts, organic compounds, and pathogens compared to traditional reverse osmosis systems. Nanofiltration membranes typically target divalent and larger monovalent ions, providing softer water but less comprehensive desalination than LPRO, which achieves higher salt rejection rates while maintaining lower operational pressures.

Selective Permeability

Reverse osmosis membranes exhibit higher selective permeability by rejecting nearly 99% of dissolved salts and contaminants, making them ideal for producing highly purified water. Nanofiltration membranes allow selective passage of monovalent ions while effectively removing divalent and larger molecules, offering a balance between water purity and energy efficiency.

Monovalent Ion Rejection

Reverse osmosis membranes achieve near-complete rejection of monovalent ions such as sodium and chloride, typically exceeding 99%, making them highly effective for desalination and ultrapure water production. Nanofiltration membranes selectively reject divalent and larger ions while allowing partial passage of monovalent ions, generally achieving 20-70% rejection of sodium and chloride, thus offering energy-efficient softening and partial salt removal.

Permeate Flux Optimization

Permeate flux optimization in reverse osmosis (RO) systems relies on high-pressure operation and dense membrane structures to achieve near-complete salt rejection, while nanofiltration (NF) balances moderate pressure with selective solute removal to enhance flux rates for specific applications. RO membranes typically yield permeate flux rates of 20-40 L/m2*h under 10-16 bar, whereas NF membranes operate at lower pressures (4-8 bar) with fluxes ranging from 30-60 L/m2*h, enabling energy-efficient treatment with targeted contaminant separation.

Fouling Resistant Membranes

Reverse osmosis membranes offer high contaminant rejection but are more prone to fouling due to smaller pore sizes trapping more particles, whereas nanofiltration membranes feature larger pores that resist fouling by allowing certain solutes to pass while retaining divalent ions and organic molecules. Fouling-resistant membranes in nanofiltration improve operational efficiency and lifespan by reducing fouling rates, which lowers cleaning frequency and maintenance costs compared to traditional reverse osmosis systems.

Hybrid Membrane Systems

Hybrid membrane systems combining reverse osmosis and nanofiltration optimize water treatment by leveraging reverse osmosis's high salt rejection with nanofiltration's selective removal of divalent ions and organic matter. These integrated systems enhance energy efficiency, reduce fouling, and improve overall water quality, making them ideal for complex applications such as wastewater reuse and desalination.

Emerging Contaminants Removal

Reverse osmosis effectively removes a broad spectrum of emerging contaminants, including pharmaceuticals, pesticides, and endocrine-disrupting compounds, due to its dense membrane structure with pore sizes typically around 0.0001 microns. Nanofiltration offers selective removal of larger organic molecules and divalent ions, efficiently targeting certain emerging contaminants while maintaining higher water permeability and lower energy consumption compared to reverse osmosis.

Energy Recovery Devices (ERDs)

Reverse osmosis systems equipped with Energy Recovery Devices (ERDs) can achieve energy savings of up to 60% compared to nanofiltration units, which typically operate at lower pressures and have limited ERD integration. While nanofiltration membranes remove divalent ions with moderate energy consumption, ERDs in reverse osmosis efficiently capture hydraulic energy from high-pressure brine streams, enhancing overall system energy efficiency.

Brine Management Technologies

Reverse osmosis brine management relies on high-pressure membranes to remove up to 99% of dissolved salts, resulting in concentrated brine requiring advanced disposal or recovery methods like zero liquid discharge systems; nanofiltration produces lower concentration brine with partial salt rejection, enabling more energy-efficient treatment and easier integration with biological or chemical recovery processes. Optimizing brine handling from reverse osmosis and nanofiltration enhances water reuse sustainability by minimizing environmental impact and maximizing resource recovery through tailored membrane selection and post-treatment technologies.

Reverse Osmosis vs Nanofiltration Infographic

industrydif.com

industrydif.com