Ultra-pure water is processed through advanced filtration, reverse osmosis, and ultraviolet oxidation to remove nearly all contaminants, including organic and inorganic substances, making it essential for pharmaceutical and semiconductor industries. Deionized water specifically targets ion removal through ion exchange resins but may still contain non-ionic impurities, limiting its use in highly sensitive applications. Choosing between ultra-pure and deionized water depends on the required purity level and the specific industrial or laboratory needs.

Table of Comparison

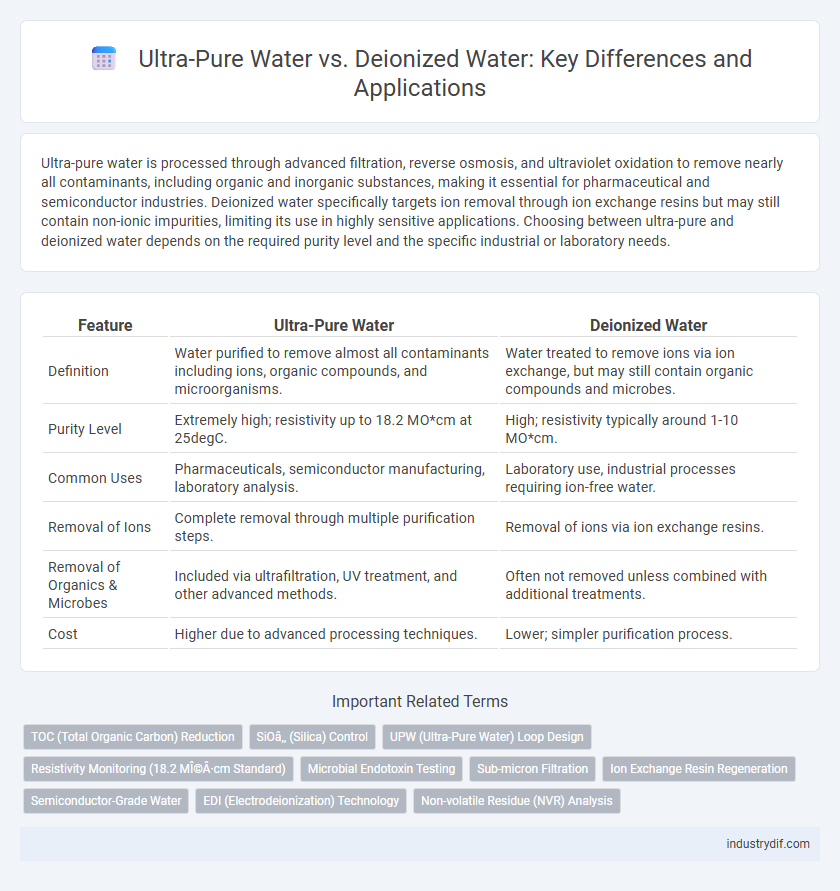

| Feature | Ultra-Pure Water | Deionized Water |

|---|---|---|

| Definition | Water purified to remove almost all contaminants including ions, organic compounds, and microorganisms. | Water treated to remove ions via ion exchange, but may still contain organic compounds and microbes. |

| Purity Level | Extremely high; resistivity up to 18.2 MO*cm at 25degC. | High; resistivity typically around 1-10 MO*cm. |

| Common Uses | Pharmaceuticals, semiconductor manufacturing, laboratory analysis. | Laboratory use, industrial processes requiring ion-free water. |

| Removal of Ions | Complete removal through multiple purification steps. | Removal of ions via ion exchange resins. |

| Removal of Organics & Microbes | Included via ultrafiltration, UV treatment, and other advanced methods. | Often not removed unless combined with additional treatments. |

| Cost | Higher due to advanced processing techniques. | Lower; simpler purification process. |

Introduction to Water Purification in Industry

Ultra-pure water and deionized water serve critical roles in industrial water purification processes, with ultra-pure water undergoing extensive filtration to remove organic compounds, bacteria, and dissolved gases beyond standard ion removal. Deionized water is produced by ion exchange resins that eliminate charged particles, delivering water with low mineral content essential for manufacturing and laboratory applications. Industries such as electronics, pharmaceuticals, and power generation rely on ultra-pure water for contamination-sensitive processes, while deionized water is commonly used where mineral-free water is adequate.

Defining Ultra-Pure Water (UPW)

Ultra-Pure Water (UPW) is water that has been purified to the highest standards, removing nearly all organic and inorganic contaminants, ions, and particles to achieve resistivity values often exceeding 18.2 MO*cm. UPW is essential in semiconductor manufacturing, pharmaceutical production, and laboratories requiring contamination-free conditions. Its stringent purification processes include reverse osmosis, ultrafiltration, deionization, and advanced oxidation technologies to ensure unmatched purity levels.

Understanding Deionized Water (DI Water)

Deionized water (DI water) is water that has had its mineral ions, such as calcium, sodium, and chloride, removed through ion exchange resins, resulting in highly purified water. It is commonly used in laboratory processes, pharmaceutical manufacturing, and electronics cleaning, where the absence of ionic contaminants is critical. Unlike ultra-pure water, which undergoes additional purification steps including filtration and UV treatment to remove organic compounds and microorganisms, deionized water primarily targets ionic impurities.

Key Differences: Ultra-Pure Water vs Deionized Water

Ultra-pure water contains extremely low levels of total dissolved solids (TDS), organic compounds, and biological contaminants, achieving resistivity above 18.2 megohm-cm, making it ideal for semiconductor manufacturing and pharmaceutical applications. Deionized water is produced by ion exchange resins removing mineral ions but may still contain organic impurities and bacteria, resulting in lower purity levels compared to ultra-pure water. The key difference lies in the purification methods and contaminant removal, with ultra-pure water requiring additional filtration, reverse osmosis, and UV treatment to achieve superior chemical purity and conductivity.

Purification Processes: Methods and Technologies

Ultra-pure water undergoes advanced purification processes including reverse osmosis, ultrafiltration, electrodeionization, and UV oxidation to achieve extremely low levels of contaminants and organic compounds. Deionized water is produced primarily through ion-exchange resins that remove ionic impurities by replacing cations and anions with hydrogen and hydroxyl ions. Both methods focus on removing impurities but ultra-pure water employs multi-stage technologies for superior purity required in semiconductor manufacturing and pharmaceutical applications.

Industry Applications for Ultra-Pure Water

Ultra-pure water is essential in semiconductor manufacturing, pharmaceutical production, and power generation due to its extremely low levels of organic and inorganic contaminants. Its stringent purity standards prevent equipment corrosion and ensure product quality in microelectronics and lab environments. Compared to deionized water, ultra-pure water offers comprehensive removal of dissolved solids, microbes, and organics, making it irreplaceable in high-precision industrial processes.

Industry Applications for Deionized Water

Deionized water is extensively used in industries such as pharmaceuticals, electronics manufacturing, and chemical processing due to its ability to remove ionic impurities that can interfere with sensitive processes. Its high purity level helps prevent equipment corrosion, contamination, and unwanted chemical reactions, ensuring product quality and operational reliability. Unlike ultra-pure water, deionized water offers a cost-effective solution for applications requiring low conductivity and minimal ionic content.

Quality Standards and Regulatory Requirements

Ultra-pure water meets stringent quality standards, including Resistivity greater than 18.2 MO*cm and Total Organic Carbon (TOC) levels below 1 ppb, making it essential for semiconductor manufacturing and pharmaceutical applications. Deionized water is primarily regulated by ASTM D1193 Type II or III standards, focusing on ion removal but does not guarantee removal of organic compounds or microbes. Regulatory requirements like USP and EP emphasize ultra-pure water testing for endotoxins and microbial contamination, ensuring compliance in sensitive industries.

Cost Comparison and Operational Considerations

Ultra-pure water typically incurs higher costs than deionized water due to advanced purification technologies such as reverse osmosis and continuous electrodeionization, which demand more energy and maintenance. Deionized water systems are generally more cost-effective, requiring less complex infrastructure and simpler resin regeneration processes, making them favorable for applications with moderate purity needs. Operationally, ultra-pure water systems necessitate rigorous monitoring and frequent system validation to maintain stringent quality standards, whereas deionized water systems offer easier maintenance but may require additional treatment steps for ultrapure applications.

Choosing the Right Water Type for Your Application

Ultra-pure water, characterized by its extremely low conductivity and minimal organic and inorganic contaminants, is ideal for sensitive laboratory applications and semiconductor manufacturing where contamination control is critical. Deionized water, produced through ion-exchange resins removing charged particles, suits industrial processes and general lab use requiring fewer purity constraints. Selecting between ultra-pure and deionized water depends on the specific application's purity requirements, contamination sensitivity, and cost considerations, ensuring optimal performance and reliability.

Related Important Terms

TOC (Total Organic Carbon) Reduction

Ultra-pure water exhibits significantly lower Total Organic Carbon (TOC) levels compared to deionized water, often achieving TOC concentrations below 1 ppb ideal for semiconductor manufacturing and pharmaceutical applications. Deionized water primarily removes ionic contaminants but typically has higher TOC levels, ranging from 10 to 50 ppb, limiting its use where ultra-low organic content is critical.

SiO₂ (Silica) Control

Ultra-pure water achieves significantly lower silica (SiO2) levels, often below 1 ppb, through advanced purification methods including reverse osmosis and ultrafiltration, making it ideal for semiconductor and pharmaceutical industries. Deionized water typically contains higher silica concentrations, as ion exchange resins are less effective at removing dissolved silica, limiting its use where stringent silica control is critical.

UPW (Ultra-Pure Water) Loop Design

Ultra-Pure Water (UPW) loop design prioritizes continuous circulation, temperature control, and high-efficiency filtration to maintain resistivity above 18.2 MO*cm and minimize microbial contamination. Critical components include ultraviolet (UV) sterilizers, submicron filters, and corrosion-resistant piping to ensure consistent purity for semiconductor and pharmaceutical applications.

Resistivity Monitoring (18.2 MΩ·cm Standard)

Ultra-pure water achieves a resistivity of 18.2 MO*cm at 25degC, the benchmark for high-purity standards, monitored continuously to ensure minimal ionic contamination. Deionized water, while purified by ion exchange resins, typically exhibits lower resistivity levels and lacks the stringent resistivity monitoring essential for applications demanding ultra-pure water quality.

Microbial Endotoxin Testing

Ultra-pure water is preferred over deionized water for microbial endotoxin testing due to its lower organic and ionic contaminants, ensuring more accurate and reliable endotoxin detection. Deionized water lacks the stringent purification steps that remove endotoxins, potentially leading to false-positive results in sensitive pharmaceutical and biotechnology assays.

Sub-micron Filtration

Ultra-pure water undergoes advanced sub-micron filtration processes, including reverse osmosis and ultrafiltration, to remove particles smaller than one micron, ensuring minimal contaminants for high-precision applications. Deionized water relies primarily on ion-exchange resins to eliminate ionic impurities but does not inherently remove sub-micron particles, making ultra-pure water superior for scenarios requiring stringent particulate control.

Ion Exchange Resin Regeneration

Ultra-pure water is produced through multi-stage purification processes including reverse osmosis and electrodeionization, while deionized water primarily relies on ion exchange resin regeneration to remove dissolved ions by replacing them with H+ and OH- ions; resin regeneration cycles use acidic and alkaline solutions to restore ion exchange capacity. Efficient regeneration of ion exchange resins is critical to maintaining water quality in deionized water systems, preventing exhaustion, and ensuring consistent removal of cations and anions during purification.

Semiconductor-Grade Water

Semiconductor-grade water requires ultra-pure water with resistivity above 18.2 MO*cm and extremely low particulates, ions, and organic contaminants to prevent defects in microchip fabrication. Deionized water, while free of most charged ions, often lacks the stringent filtration and purification steps such as reverse osmosis and UV oxidation needed for semiconductor applications.

EDI (Electrodeionization) Technology

Electrodeionization (EDI) technology produces ultra-pure water by continuously removing ionized species from deionized water using electrically active media and ion exchange membranes, enhancing water purity beyond conventional deionization methods. EDI systems combine regenerative ion exchange resins with electrical current to reduce chemical use, lower operational costs, and provide a sustainable and consistent source of ultra-pure water suitable for critical applications such as pharmaceuticals and semiconductor manufacturing.

Non-volatile Residue (NVR) Analysis

Ultra-pure water exhibits significantly lower non-volatile residue (NVR) levels compared to deionized water, making it ideal for applications requiring minimal chemical contamination. NVR analysis reveals that ultra-pure water contains fewer dissolved solids and impurities, ensuring higher purity standards essential for pharmaceutical and semiconductor industries.

Ultra-Pure Water vs Deionized Water Infographic

industrydif.com

industrydif.com