Effective inventory management ensures optimal stock levels to meet customer demand without overstocking or stockouts. Predictive analytics enhances this process by using historical data and market trends to forecast future inventory needs accurately. Combining both strategies reduces costs and improves supply chain efficiency in wholesale operations.

Table of Comparison

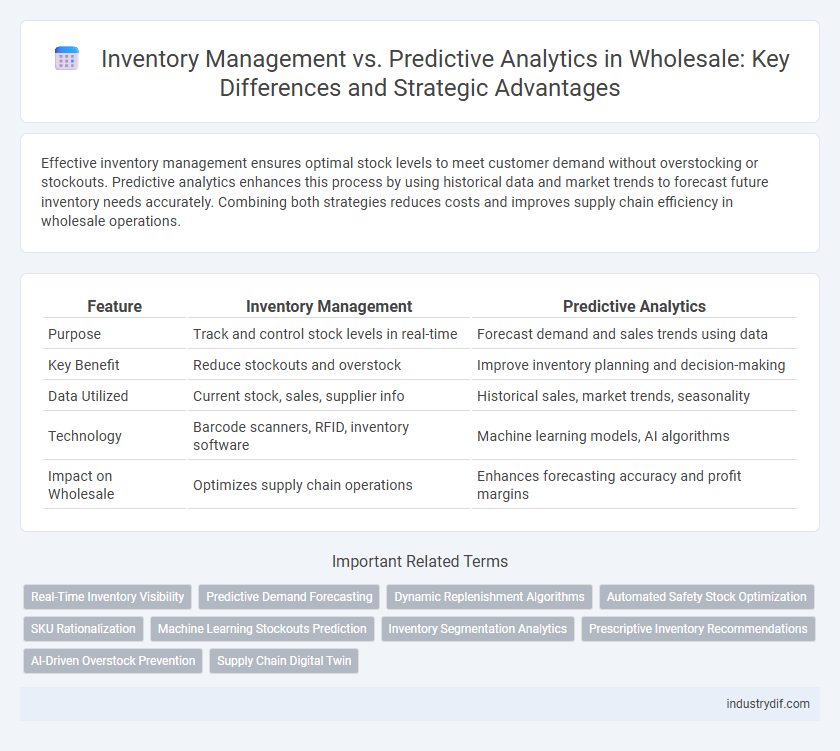

| Feature | Inventory Management | Predictive Analytics |

|---|---|---|

| Purpose | Track and control stock levels in real-time | Forecast demand and sales trends using data |

| Key Benefit | Reduce stockouts and overstock | Improve inventory planning and decision-making |

| Data Utilized | Current stock, sales, supplier info | Historical sales, market trends, seasonality |

| Technology | Barcode scanners, RFID, inventory software | Machine learning models, AI algorithms |

| Impact on Wholesale | Optimizes supply chain operations | Enhances forecasting accuracy and profit margins |

Understanding Inventory Management in Wholesale

Inventory management in wholesale involves tracking stock levels, orders, sales, and deliveries to ensure optimal product availability and minimize holding costs. Efficient inventory control relies on accurate data analysis, reorder point calculation, and demand forecasting to prevent stockouts and overstock situations. Integrating predictive analytics enhances traditional inventory management by using historical sales patterns and market trends to anticipate demand fluctuations and optimize inventory turnover.

The Role of Predictive Analytics in Wholesale Operations

Predictive analytics leverages historical sales data, market trends, and customer behavior to forecast inventory demand, reducing stockouts and overstock situations in wholesale operations. By analyzing patterns and external factors, wholesalers can optimize inventory levels, improve order accuracy, and enhance supply chain efficiency. Integrating predictive models with inventory management systems enables proactive decision-making, leading to cost savings and increased customer satisfaction.

Key Differences Between Inventory Management and Predictive Analytics

Inventory management centers on tracking stock levels, replenishing goods, and optimizing storage to meet current demand efficiently, while predictive analytics uses historical data and statistical algorithms to forecast future trends and customer buying behaviors. Inventory management ensures operational continuity by preventing stockouts and overstock situations, whereas predictive analytics drives strategic decision-making by anticipating market changes and demand fluctuations. Combining both enhances wholesale efficiency through real-time inventory control and accurate demand prediction, reducing costs and improving customer satisfaction.

Benefits of Inventory Management for Wholesale Businesses

Inventory management in wholesale businesses improves stock accuracy, reduces carrying costs, and prevents stockouts or overstock situations, leading to enhanced operational efficiency. Effective inventory systems enable real-time tracking, streamline order fulfillment, and increase customer satisfaction by ensuring product availability. These benefits contribute to optimized cash flow and higher profitability in wholesale operations.

Advantages of Predictive Analytics in Wholesale Supply Chains

Predictive analytics enhances wholesale supply chain efficiency by accurately forecasting demand trends, reducing overstock and stockouts. It leverages historical sales data and market indicators to optimize inventory levels, minimizing holding costs and improving cash flow. Wholesale distributors benefit from proactive decision-making powered by predictive algorithms, leading to increased customer satisfaction and streamlined operations.

Integrating Predictive Analytics with Inventory Management Systems

Integrating predictive analytics with inventory management systems enhances wholesale operations by accurately forecasting demand and optimizing stock levels, reducing overstock and stockouts. Advanced algorithms analyze historical sales data, market trends, and seasonal fluctuations to improve reorder timing and quantity decisions. This fusion streamlines supply chain efficiency, lowers holding costs, and boosts customer satisfaction through timely product availability.

Data-Driven Decision Making in Wholesale Inventory Control

Wholesale inventory control leverages predictive analytics to enhance data-driven decision making by analyzing historical sales patterns and demand fluctuations, enabling more accurate stock replenishment and reduced carrying costs. Advanced algorithms forecast inventory needs, minimizing stockouts and overstock situations, which improves cash flow and operational efficiency. Integrating real-time data with predictive models allows wholesalers to optimize inventory turnover and respond swiftly to market changes.

Challenges of Implementing Predictive Analytics in Wholesale

Implementing predictive analytics in wholesale faces challenges such as data integration complexities, inconsistent data quality, and the high costs of advanced analytics tools. Many wholesalers struggle to align predictive models with existing inventory management systems, resulting in inaccurate demand forecasts and inefficient stock levels. Limited expertise in data science hampers the ability to fully leverage predictive analytics, restricting its potential to optimize inventory turnover and reduce holding costs.

Real-World Applications: Inventory Management vs Predictive Analytics

Inventory management in wholesale ensures accurate stock levels and reduces holding costs by using real-time tracking systems, barcode scanning, and automated replenishment. Predictive analytics applies historical sales data, market trends, and seasonality patterns to forecast demand, optimize order quantities, and minimize stockouts. Combining these approaches improves supply chain efficiency, enhances customer satisfaction, and drives profitability in wholesale operations.

Future Trends in Wholesale: Evolving from Inventory Management to Predictive Analytics

Future trends in wholesale are shifting from traditional inventory management to advanced predictive analytics, enabling businesses to forecast demand with greater accuracy and optimize stock levels dynamically. Leveraging machine learning algorithms and real-time data integration, predictive analytics minimizes stockouts and overstock situations, enhancing supply chain efficiency. This transition supports wholesalers in reducing operational costs while improving customer satisfaction through more responsive inventory practices.

Related Important Terms

Real-Time Inventory Visibility

Real-time inventory visibility enhances wholesale operations by providing accurate, up-to-the-minute data on stock levels, reducing stockouts and overstocks. Predictive analytics leverages this live data to forecast demand trends, enabling proactive inventory replenishment and optimized supply chain management.

Predictive Demand Forecasting

Predictive demand forecasting leverages machine learning algorithms and historical sales data to optimize inventory levels, reducing stockouts and minimizing excess stock in wholesale operations. Advanced analytics provide wholesalers with accurate future demand insights, enhancing supply chain efficiency and improving customer satisfaction.

Dynamic Replenishment Algorithms

Dynamic replenishment algorithms leverage predictive analytics to optimize inventory management by forecasting demand patterns and adjusting stock levels in real-time, significantly reducing stockouts and overstock scenarios. Integrating these algorithms into wholesale operations enhances supply chain efficiency and customer satisfaction by ensuring product availability while minimizing holding costs.

Automated Safety Stock Optimization

Automated safety stock optimization leverages predictive analytics to analyze historical sales data, lead times, and demand variability, enabling wholesalers to maintain optimal inventory levels while reducing stockouts and excess holding costs. Integrating predictive analytics into inventory management systems enhances accuracy in forecasting demand fluctuations, streamlining replenishment processes and improving overall supply chain efficiency.

SKU Rationalization

Effective SKU rationalization in wholesale relies on integrating inventory management with predictive analytics to optimize stock levels and reduce holding costs. Predictive analytics enhances forecasting accuracy by identifying high-performing SKUs, enabling better decision-making for inventory replenishment and minimizing obsolete stock.

Machine Learning Stockouts Prediction

Machine learning-driven predictive analytics significantly enhances inventory management in wholesale by accurately forecasting stockouts, reducing overstock and understock scenarios. Leveraging historical sales data and real-time market trends, these models optimize reorder points and inventory levels to improve supply chain efficiency and customer satisfaction.

Inventory Segmentation Analytics

Inventory segmentation analytics enhances predictive analytics in wholesale by categorizing stock based on demand patterns, turnover rates, and profitability, enabling precise inventory management. This targeted approach optimizes stock levels, reduces holding costs, and improves order fulfillment efficiency by forecasting segment-specific inventory needs.

Prescriptive Inventory Recommendations

Prescriptive inventory recommendations leverage predictive analytics to optimize stock levels, reducing holding costs while preventing stockouts in wholesale operations. Integrating real-time sales data with advanced algorithms enables wholesalers to make data-driven decisions that enhance supply chain efficiency and responsiveness.

AI-Driven Overstock Prevention

AI-driven overstock prevention leverages predictive analytics and machine learning algorithms to analyze historical sales data, seasonal trends, and market demand fluctuations, enabling wholesalers to optimize inventory levels accurately. Effective inventory management through these technologies reduces excess stock, minimizes holding costs, and improves cash flow by aligning supply with real-time demand forecasts.

Supply Chain Digital Twin

Inventory management in wholesale leverages a supply chain digital twin to simulate real-time stock levels and demand fluctuations, enabling precise replenishment and reducing holding costs. Predictive analytics enhances this digital replica by forecasting future inventory needs based on historical data and market trends, optimizing order quantities and improving overall supply chain efficiency.

Inventory Management vs Predictive Analytics Infographic

industrydif.com

industrydif.com