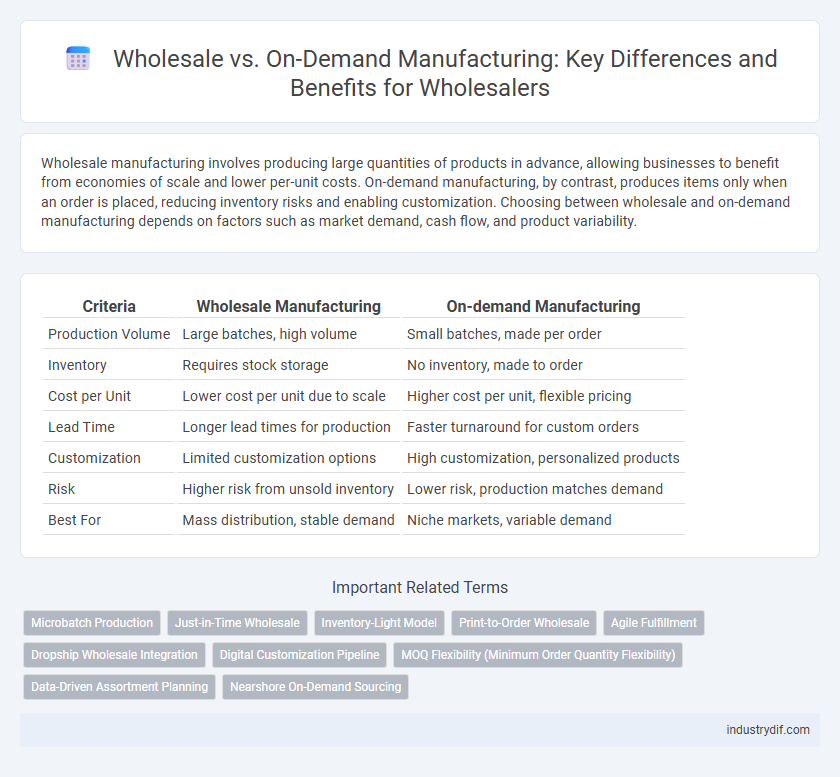

Wholesale manufacturing involves producing large quantities of products in advance, allowing businesses to benefit from economies of scale and lower per-unit costs. On-demand manufacturing, by contrast, produces items only when an order is placed, reducing inventory risks and enabling customization. Choosing between wholesale and on-demand manufacturing depends on factors such as market demand, cash flow, and product variability.

Table of Comparison

| Criteria | Wholesale Manufacturing | On-demand Manufacturing |

|---|---|---|

| Production Volume | Large batches, high volume | Small batches, made per order |

| Inventory | Requires stock storage | No inventory, made to order |

| Cost per Unit | Lower cost per unit due to scale | Higher cost per unit, flexible pricing |

| Lead Time | Longer lead times for production | Faster turnaround for custom orders |

| Customization | Limited customization options | High customization, personalized products |

| Risk | Higher risk from unsold inventory | Lower risk, production matches demand |

| Best For | Mass distribution, stable demand | Niche markets, variable demand |

Definition of Wholesale Manufacturing

Wholesale manufacturing involves producing large quantities of products that are sold to retailers, distributors, or other businesses rather than directly to consumers. This method emphasizes economies of scale, reducing production costs per unit and enabling competitive pricing in bulk orders. Wholesale manufacturers typically maintain inventory to meet large-volume demand and support consistent supply chains.

Understanding On-demand Manufacturing

On-demand manufacturing produces goods as orders are received, reducing inventory costs and minimizing waste compared to wholesale's bulk production. This approach leverages digital technologies like 3D printing and automated workflows to swiftly respond to market trends and customer demands. On-demand manufacturing enhances flexibility and customization, enabling businesses to deliver tailored products without the risks associated with overproduction.

Key Differences Between Wholesale and On-demand Manufacturing

Wholesale manufacturing involves producing large quantities of standardized products in advance, enabling bulk sales and lower per-unit costs. On-demand manufacturing focuses on producing items only after an order is received, reducing inventory risks and allowing for greater customization. Key differences include production volume, inventory management, and flexibility in responding to market demand.

Pros and Cons of Wholesale Manufacturing

Wholesale manufacturing offers cost advantages through bulk production, enabling lower per-unit prices and increased profit margins for retailers. However, it requires significant upfront investment in inventory and storage, posing risks related to unsold stock and demand fluctuations. Limited flexibility to customize products compared to on-demand manufacturing restricts responsiveness to market trends and consumer preferences.

Advantages and Disadvantages of On-demand Manufacturing

On-demand manufacturing offers significant advantages such as reduced inventory costs, minimized waste, and increased customization capabilities, making it ideal for businesses seeking agility and cost efficiency. However, limitations include longer production lead times compared to wholesale manufacturing and potential higher per-unit costs due to smaller batch sizes. This manufacturing model suits companies prioritizing flexibility over volume discounts, whereas wholesale remains preferable for large-scale, cost-effective distribution.

Cost Comparison: Wholesale vs On-demand

Wholesale manufacturing typically offers lower per-unit costs due to bulk production efficiencies, making it more cost-effective for large orders. On-demand manufacturing incurs higher costs per unit because of flexible, smaller batch production and shorter lead times. Businesses must weigh the upfront investment savings in wholesale against the agility and reduced inventory expenses of on-demand models.

Inventory Management in Wholesale vs On-demand

Wholesale inventory management involves maintaining stock in bulk to meet consistent demand, optimizing storage costs and supply chain efficiency. On-demand manufacturing eliminates excess inventory by producing goods only after receiving orders, reducing storage expenses and minimizing risk of unsold stock. Wholesale relies on accurate demand forecasting to balance stock availability, while on-demand prioritizes flexibility and rapid production cycles over inventory holding.

Impact on Supply Chain Efficiency

Wholesale manufacturing streamlines supply chain efficiency by producing large quantities of products in advance, facilitating bulk inventory storage and predictable distribution schedules. On-demand manufacturing, however, minimizes inventory costs and reduces waste by producing goods only when ordered, enhancing responsiveness to market fluctuations and reducing lead times. While wholesale relies on forecasting accuracy, on-demand manufacturing offers greater agility, directly impacting supply chain flexibility and operational costs.

Sustainability Considerations

Wholesale manufacturing often achieves greater sustainability through economies of scale, reducing per-unit resource consumption and waste compared to on-demand manufacturing. On-demand manufacturing, while minimizing inventory and overproduction, can lead to higher energy use per item due to frequent machine setups and smaller batch sizes. Companies seeking sustainable production must balance the efficiency of bulk production with the waste reduction benefits of on-demand models to optimize their environmental impact.

Choosing the Right Manufacturing Model for Your Business

Wholesale manufacturing involves producing large quantities of products for distribution to multiple retailers, optimizing economies of scale and reducing per-unit costs, ideal for businesses targeting broad market reach. On-demand manufacturing allows production based on immediate orders, minimizing inventory costs and enabling customization, making it suitable for businesses with variable demand and niche markets. Analyze your sales forecasts, cash flow, and customer needs to decide between bulk production efficiency in wholesale or the flexibility and responsiveness of on-demand manufacturing.

Related Important Terms

Microbatch Production

Microbatch production in wholesale offers scalable flexibility by producing smaller inventory lots tailored to specific demand patterns, reducing storage costs and minimizing waste compared to large-scale on-demand manufacturing. This approach enhances supply chain responsiveness while maintaining cost efficiency and consistent product quality.

Just-in-Time Wholesale

Just-in-Time Wholesale revolutionizes inventory management by aligning supply closely with demand, minimizing storage costs and reducing waste compared to traditional bulk wholesale purchasing. This model enhances cash flow efficiency and responsiveness by delivering products precisely when needed, bridging the gap between wholesale scalability and on-demand manufacturing flexibility.

Inventory-Light Model

Wholesale relies on bulk production and significant inventory storage to meet large order demands, while the inventory-light model in on-demand manufacturing minimizes stock holding by producing goods only as orders are placed. This approach reduces upfront costs, lowers warehousing expenses, and enhances supply chain flexibility for businesses adapting to fluctuating market demands.

Print-to-Order Wholesale

Print-to-Order Wholesale combines the scalability of wholesale with the customization of on-demand manufacturing, enabling businesses to produce bulk orders only after receiving specific customer demands, reducing inventory costs and minimizing waste. This hybrid model leverages digital printing technology and automated workflows to efficiently fulfill large volume orders while maintaining product personalization and rapid turnaround times.

Agile Fulfillment

Wholesale offers bulk inventory availability that supports steady demand cycles, while On-demand Manufacturing leverages Agile Fulfillment to rapidly customize and deliver products with minimal lead times. Agile Fulfillment integrates real-time data and flexible production workflows, enabling businesses to respond swiftly to market fluctuations and reduce excess inventory.

Dropship Wholesale Integration

Wholesale offers bulk inventory management and predictable supply chains ideal for Dropship Wholesale Integration, enabling seamless order fulfillment without holding stock. On-demand manufacturing provides customization and reduced inventory risks but often involves longer lead times, making it less compatible with instant dropshipping needs.

Digital Customization Pipeline

The digital customization pipeline in wholesale manufacturing streamlines bulk production by integrating automated design tools and real-time data analytics to enable rapid, cost-effective adjustments across large orders. On-demand manufacturing leverages this pipeline to offer flexible, small-batch customization, reducing inventory costs and accelerating time-to-market through digital interfaces that directly connect customer specifications with production systems.

MOQ Flexibility (Minimum Order Quantity Flexibility)

Wholesale typically requires higher Minimum Order Quantities (MOQs), which can limit flexibility for small businesses or startups, while on-demand manufacturing offers greater MOQ flexibility, allowing orders of varying sizes tailored to specific needs. This adaptability in on-demand production reduces inventory risk and upfront costs compared to the bulk purchasing model of traditional wholesale.

Data-Driven Assortment Planning

Wholesale leverages historical sales data and market trends to optimize inventory levels and product mix, minimizing stockouts and overstock risks through data-driven assortment planning. On-demand manufacturing uses real-time customer demand analytics to tailor production schedules, reducing lead times and inventory costs while aligning closely with current market needs.

Nearshore On-Demand Sourcing

Nearshore on-demand sourcing offers faster turnaround times and reduced shipping costs compared to traditional wholesale models, enabling businesses to respond quickly to market demands. This approach enhances supply chain agility and minimizes inventory holding risks by producing goods closer to the end consumer.

Wholesale vs On-demand Manufacturing Infographic

industrydif.com

industrydif.com