Inventory turnover measures how quickly stock is sold and replaced, providing insight into product demand and operational efficiency in wholesale. Predictive replenishment uses data analytics and forecasting to optimize stock levels, reducing the risk of overstocking or stockouts. Combining inventory turnover metrics with predictive replenishment strategies enhances supply chain responsiveness and profitability.

Table of Comparison

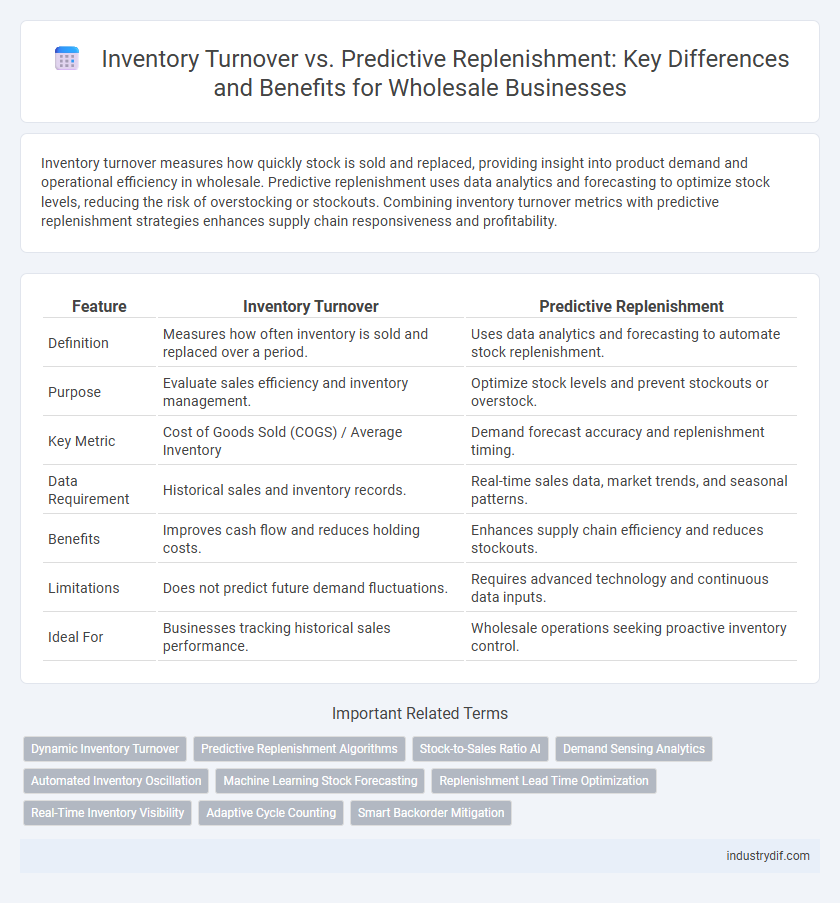

| Feature | Inventory Turnover | Predictive Replenishment |

|---|---|---|

| Definition | Measures how often inventory is sold and replaced over a period. | Uses data analytics and forecasting to automate stock replenishment. |

| Purpose | Evaluate sales efficiency and inventory management. | Optimize stock levels and prevent stockouts or overstock. |

| Key Metric | Cost of Goods Sold (COGS) / Average Inventory | Demand forecast accuracy and replenishment timing. |

| Data Requirement | Historical sales and inventory records. | Real-time sales data, market trends, and seasonal patterns. |

| Benefits | Improves cash flow and reduces holding costs. | Enhances supply chain efficiency and reduces stockouts. |

| Limitations | Does not predict future demand fluctuations. | Requires advanced technology and continuous data inputs. |

| Ideal For | Businesses tracking historical sales performance. | Wholesale operations seeking proactive inventory control. |

Understanding Inventory Turnover in Wholesale

Inventory turnover in wholesale measures how many times inventory is sold and replaced within a specific period, reflecting the efficiency of stock management and cash flow optimization. Higher turnover rates indicate effective demand forecasting and reduce holding costs, which minimizes outdated or excess inventory risks. Analyzing inventory turnover helps wholesalers align purchasing decisions with market demand and implement predictive replenishment strategies for seamless supply chain operations.

What Is Predictive Replenishment?

Predictive replenishment uses advanced data analytics and machine learning algorithms to forecast inventory needs based on historical sales, seasonal trends, and market demand. This approach helps wholesalers optimize stock levels, reduce carrying costs, and avoid stockouts by anticipating customer demand more accurately than traditional inventory turnover methods. By leveraging real-time data, predictive replenishment streamlines supply chain efficiency and enhances profitability in wholesale operations.

Key Differences: Inventory Turnover vs Predictive Replenishment

Inventory turnover measures how often stock is sold and replaced over a specific period, reflecting sales efficiency and inventory management in wholesale operations. Predictive replenishment uses historical data and advanced analytics to forecast demand, optimizing stock levels to prevent overstocking or stockouts. Key differences lie in inventory turnover's reactive nature based on past sales velocity, while predictive replenishment proactively anticipates future inventory needs to enhance supply chain responsiveness.

Benefits of High Inventory Turnover for Wholesalers

High inventory turnover enables wholesalers to reduce holding costs and minimize the risk of obsolete stock, improving cash flow and operational efficiency. By regularly selling and replenishing products, wholesalers can respond faster to market demand changes, ensuring product availability and customer satisfaction. This dynamic approach supports lean inventory management, optimizing warehouse space and boosting profitability.

How Predictive Replenishment Optimizes Stock Levels

Predictive replenishment leverages advanced analytics and real-time sales data to enhance inventory turnover by accurately forecasting demand, reducing stockouts and overstock situations. This method optimizes stock levels by aligning reorder points with consumption patterns, ensuring wholesalers maintain optimal inventory without excess carrying costs. Improved stock availability directly supports customer satisfaction and operational efficiency in wholesale distribution.

Impact on Cash Flow: Comparing Both Strategies

Inventory turnover directly influences cash flow by accelerating the conversion of stock into sales, reducing holding costs, and freeing up working capital for operational needs. Predictive replenishment leverages data analytics to forecast demand accurately, minimizing stockouts and overstock, which stabilizes cash flow and optimizes inventory investment. Comparing both, inventory turnover emphasizes speed and efficiency in sales, while predictive replenishment enhances cash flow predictability through strategic inventory management.

Technology’s Role in Inventory Management

Advanced inventory turnover metrics combined with predictive replenishment systems leverage AI and machine learning to optimize stock levels, reducing excess inventory and preventing stockouts. Real-time data analytics and IoT-enabled sensors provide actionable insights that enhance demand forecasting accuracy and streamline reorder processes. These technologies transform traditional wholesale inventory management into a proactive, efficient system that maximizes cash flow and customer satisfaction.

Analyzing Data for Better Replenishment Decisions

Inventory turnover rates provide critical insights into how quickly products move through wholesale channels, enabling precise demand forecasting when integrated with predictive replenishment systems. Analyzing sales velocity, seasonal trends, and historical order data allows wholesalers to optimize stock levels, reduce holding costs, and prevent stockouts. Advanced analytics tools leverage real-time inventory data to generate accurate replenishment alerts, enhancing supply chain efficiency and improving customer satisfaction.

Common Challenges in Wholesale Inventory Optimization

Wholesale inventory optimization faces common challenges such as inaccurate demand forecasting and slow inventory turnover rates, leading to overstocking or stockouts. Predictive replenishment requires sophisticated data analytics to balance inventory levels, yet many wholesalers struggle with integrating real-time sales data and supplier lead times. Inefficient coordination between inventory turnover metrics and replenishment schedules often results in higher carrying costs and lost sales opportunities.

Best Practices for Balancing Turnover and Predictive Replenishment

Optimizing inventory turnover requires accurately forecasting demand through predictive replenishment models that analyze historical sales data and market trends. Implementing real-time data analytics and automated reorder points ensures a balanced stock level, reducing both overstock and stockouts. Best practices include integrating advanced inventory management systems with supplier lead time insights to align replenishment cycles with sales velocity effectively.

Related Important Terms

Dynamic Inventory Turnover

Dynamic inventory turnover enhances wholesale efficiency by continuously adjusting stock levels based on real-time sales data and market trends, reducing overstock and stockouts. Predictive replenishment leverages these insights to forecast demand accurately, enabling wholesalers to optimize order cycles and maintain optimal inventory flow.

Predictive Replenishment Algorithms

Predictive replenishment algorithms leverage historical sales data and real-time market trends to optimize inventory levels, reducing stockouts and excess holding costs in wholesale operations. These algorithms enhance inventory turnover by forecasting demand with greater accuracy, enabling wholesalers to maintain optimal stock levels and improve cash flow efficiency.

Stock-to-Sales Ratio AI

Inventory turnover measures how frequently stock is sold and replaced over a period, while predictive replenishment leverages AI to optimize the stock-to-sales ratio by forecasting demand more accurately. Implementing AI-driven stock-to-sales ratio analysis enables wholesalers to reduce overstock and stockouts, enhancing inventory efficiency and boosting profit margins.

Demand Sensing Analytics

Inventory turnover rates improve significantly when predictive replenishment systems leverage demand sensing analytics, enabling wholesalers to forecast real-time consumer demand accurately. This approach minimizes stockouts and overstock situations by adjusting inventory levels dynamically based on market trends and purchasing behavior data.

Automated Inventory Oscillation

Inventory turnover measures how quickly stock is sold and replaced, serving as a key indicator of wholesale efficiency and cash flow management. Predictive replenishment leverages automated inventory oscillation algorithms to optimize stock levels, reduce holding costs, and prevent stockouts by dynamically adjusting orders based on sales patterns and demand forecasts.

Machine Learning Stock Forecasting

Inventory turnover rates directly impact wholesale profitability by indicating how efficiently stock is sold and replaced, while predictive replenishment uses machine learning stock forecasting to optimize reorder timing and quantities, reducing overstock and stockouts. Machine learning models analyze historical sales data, seasonality, and market trends to provide accurate demand predictions that enhance inventory management strategies.

Replenishment Lead Time Optimization

Optimizing replenishment lead time in wholesale significantly enhances inventory turnover by reducing stockouts and excess inventory, ensuring faster response to demand fluctuations. Predictive replenishment leverages data analytics to forecast optimal reorder points and quantities, minimizing lead times and improving overall supply chain efficiency.

Real-Time Inventory Visibility

Real-time inventory visibility enhances inventory turnover by providing accurate, up-to-the-minute stock levels that drive predictive replenishment strategies, minimizing stockouts and overstock situations. Implementing advanced tracking systems enables wholesalers to optimize supply chain responsiveness, reduce holding costs, and improve cash flow efficiency.

Adaptive Cycle Counting

Adaptive cycle counting enhances inventory turnover by enabling continuous, data-driven audits that predict stock needs more accurately than traditional replenishment methods. This predictive replenishment approach minimizes stockouts and excess inventory, optimizing cash flow and operational efficiency in wholesale distribution.

Smart Backorder Mitigation

Inventory turnover rates directly impact wholesale efficiency by indicating how quickly stock is sold and replaced, while predictive replenishment uses historical sales data and AI algorithms to forecast demand accurately. Implementing smart backorder mitigation combines these strategies by anticipating potential stockouts and automatically adjusting orders, reducing lost sales and improving customer satisfaction.

Inventory Turnover vs Predictive Replenishment Infographic

industrydif.com

industrydif.com