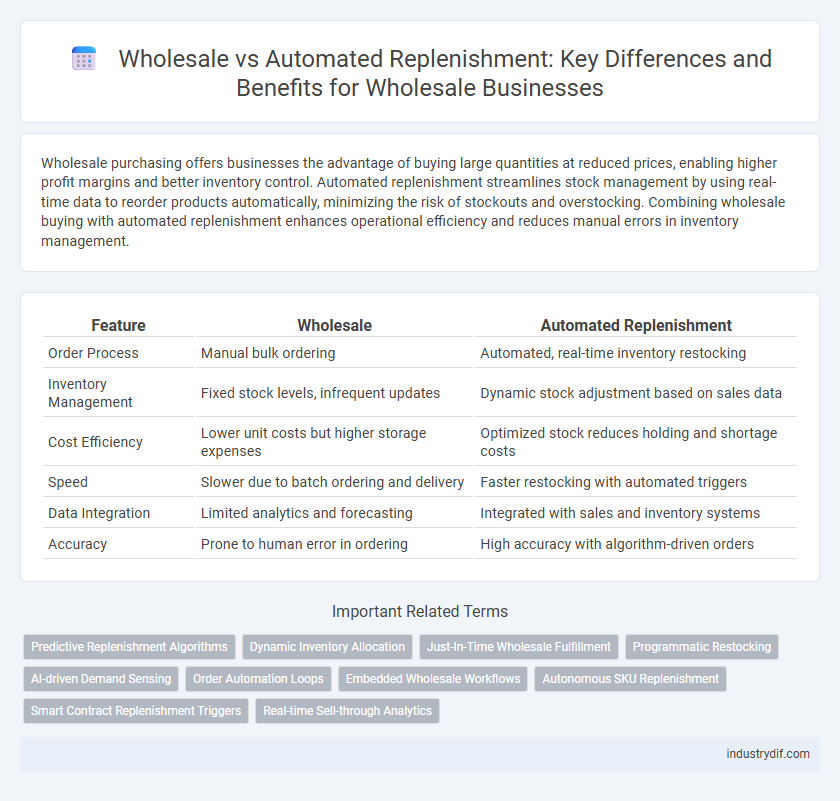

Wholesale purchasing offers businesses the advantage of buying large quantities at reduced prices, enabling higher profit margins and better inventory control. Automated replenishment streamlines stock management by using real-time data to reorder products automatically, minimizing the risk of stockouts and overstocking. Combining wholesale buying with automated replenishment enhances operational efficiency and reduces manual errors in inventory management.

Table of Comparison

| Feature | Wholesale | Automated Replenishment |

|---|---|---|

| Order Process | Manual bulk ordering | Automated, real-time inventory restocking |

| Inventory Management | Fixed stock levels, infrequent updates | Dynamic stock adjustment based on sales data |

| Cost Efficiency | Lower unit costs but higher storage expenses | Optimized stock reduces holding and shortage costs |

| Speed | Slower due to batch ordering and delivery | Faster restocking with automated triggers |

| Data Integration | Limited analytics and forecasting | Integrated with sales and inventory systems |

| Accuracy | Prone to human error in ordering | High accuracy with algorithm-driven orders |

Introduction to Wholesale and Automated Replenishment

Wholesale involves bulk purchasing of goods directly from manufacturers or distributors, enabling businesses to reduce costs and maintain inventory at competitive prices. Automated replenishment utilizes advanced software systems to monitor stock levels and trigger orders automatically, ensuring consistent product availability without manual intervention. Integrating automated replenishment within wholesale operations drives efficiency, minimizes stockouts, and optimizes inventory turnover for retailers and suppliers alike.

Key Differences Between Wholesale and Automated Replenishment

Wholesale involves bulk purchasing of goods at discounted prices for resale, emphasizing large inventory acquisition and cost savings. Automated replenishment uses technology-driven systems to monitor stock levels and trigger timely reorder processes, focusing on inventory optimization and demand forecasting. Key differences include the manual bulk buying approach in wholesale versus the data-driven, continuous inventory management in automated replenishment.

How Wholesale Models Operate

Wholesale models operate by purchasing large quantities of products directly from manufacturers or distributors, allowing businesses to benefit from bulk pricing and reduced costs. Inventory management in wholesale requires forecasting demand and storing stock until sales occur, which can lead to higher holding costs and potential overstock. Unlike automated replenishment, wholesale models rely heavily on manual orders and inventory reviews to maintain adequate supply levels.

What Is Automated Replenishment?

Automated replenishment is a technology-driven process that uses real-time inventory data and demand forecasting to automatically trigger stock orders, ensuring optimal inventory levels without manual intervention. This system enhances efficiency by reducing stockouts and overstock situations, enabling wholesalers to maintain seamless supply chain operations. By integrating automated replenishment, businesses can streamline procurement, lower operational costs, and improve customer satisfaction through consistent product availability.

Benefits of Wholesale Sourcing

Wholesale sourcing offers bulk purchasing advantages, enabling businesses to access lower unit costs and improved profit margins. It provides control over inventory selection and negotiation of favorable payment terms, enhancing cash flow management. This method supports greater flexibility in product variety and stock levels compared to automated replenishment systems.

Advantages of Automated Replenishment Systems

Automated replenishment systems significantly enhance inventory accuracy and reduce stockouts by utilizing real-time sales data and predictive analytics, ensuring optimal stock levels. These systems minimize manual intervention, leading to lower labor costs and increased operational efficiency across wholesale supply chains. Enhanced demand forecasting and seamless integration with supplier networks enable faster restocking cycles, improving customer satisfaction and reducing carrying costs.

Challenges in Wholesale Supply Chains

Wholesale supply chains face challenges such as demand variability, inventory inaccuracies, and complex supplier coordination, which complicate efficient stock management. Automated replenishment systems aim to mitigate these issues by using real-time data and predictive analytics to optimize order quantities and timing. However, integrating these systems can be hindered by legacy infrastructure, data silos, and resistance to technological adoption among wholesale partners.

How Technology Drives Automated Replenishment

Technology drives automated replenishment in wholesale by leveraging real-time inventory data, predictive analytics, and IoT sensors to ensure stock levels are optimized without manual intervention. Advanced software platforms integrate transactions and supplier information, enabling seamless reorder points and minimizing stockouts or overstock situations. Machine learning algorithms continuously analyze sales trends and seasonality, enhancing decision-making and operational efficiency in wholesale supply chains.

Choosing Between Wholesale and Automated Replenishment

Choosing between wholesale and automated replenishment depends on inventory management goals and cash flow preferences. Wholesale purchasing offers bulk discounts and control over stock levels but requires significant upfront investment and storage capacity. Automated replenishment systems optimize order frequency based on real-time sales data, reducing stockouts and excess inventory while streamlining supply chain operations.

Future Trends in Wholesale and Automated Inventory Management

Future trends in wholesale emphasize the integration of automated replenishment systems to optimize inventory turnover and reduce stockouts. Advanced data analytics and AI-driven forecasting enhance demand prediction accuracy, enabling retailers to maintain ideal inventory levels with minimal human intervention. This shift towards automated inventory management fosters greater supply chain agility, cost efficiency, and scalability in wholesale operations.

Related Important Terms

Predictive Replenishment Algorithms

Predictive replenishment algorithms leverage historical sales data and real-time market trends to optimize inventory levels in wholesale, reducing stockouts and excess inventory. These advanced algorithms forecast demand more accurately than traditional automated replenishment systems, enabling wholesalers to enhance supply chain efficiency and customer satisfaction.

Dynamic Inventory Allocation

Dynamic inventory allocation enhances wholesale operations by continuously analyzing real-time sales data and stock levels to optimize product distribution across multiple locations. This approach contrasts automated replenishment, which typically relies on fixed reorder points, by enabling greater responsiveness to demand fluctuations and reducing excess inventory costs.

Just-In-Time Wholesale Fulfillment

Just-In-Time (JIT) wholesale fulfillment optimizes inventory levels by synchronizing supply with demand, minimizing storage costs and reducing waste compared to traditional wholesale stocking methods. Automated replenishment systems enhance JIT efficiency through real-time data analysis and seamless order processing, ensuring faster turnaround and improved cash flow for wholesale distributors.

Programmatic Restocking

Programmatic restocking in wholesale leverages automated replenishment systems to predict inventory needs accurately, reducing stockouts and excess inventory while streamlining order management. This approach enhances supply chain efficiency by using data-driven algorithms to trigger timely purchases based on real-time demand forecasts and historical sales patterns.

AI-driven Demand Sensing

AI-driven demand sensing significantly enhances wholesale inventory management by accurately predicting customer demand patterns and reducing stockouts or overstock situations. Integrating automated replenishment systems with real-time data analytics optimizes order quantities and timing, resulting in increased operational efficiency and lower carrying costs.

Order Automation Loops

Order automation loops in wholesale streamline inventory management by continuously monitoring stock levels and triggering purchase orders without manual input, reducing delays and stockouts. Integrating automated replenishment enhances order accuracy and supplier collaboration, optimizing supply chain efficiency and lowering operational costs.

Embedded Wholesale Workflows

Embedded wholesale workflows streamline order processing by integrating automated replenishment systems directly into the supply chain, reducing manual intervention and minimizing stockouts. This seamless integration enhances inventory accuracy and accelerates order fulfillment, driving cost efficiency and stronger supplier relationships.

Autonomous SKU Replenishment

Wholesale businesses benefit from autonomous SKU replenishment systems that use real-time inventory data and predictive analytics to optimize stock levels without manual intervention. These automated processes reduce stockouts and overstock risks, enhancing supply chain efficiency and ensuring consistent product availability.

Smart Contract Replenishment Triggers

Smart Contract Replenishment Triggers in wholesale optimize inventory management by automatically initiating orders based on predefined conditions such as stock levels and demand forecasts, ensuring timely restocking without manual intervention. This automation reduces human error, accelerates supply chain responsiveness, and enhances operational efficiency compared to traditional wholesale replenishment methods.

Real-time Sell-through Analytics

Real-time sell-through analytics in wholesale enable businesses to track inventory movement accurately and adjust stock levels promptly, preventing overstock and stockouts. Automated replenishment leverages these analytics to streamline ordering processes, ensuring optimal inventory turnover and improved cash flow management.

Wholesale vs Automated Replenishment Infographic

industrydif.com

industrydif.com