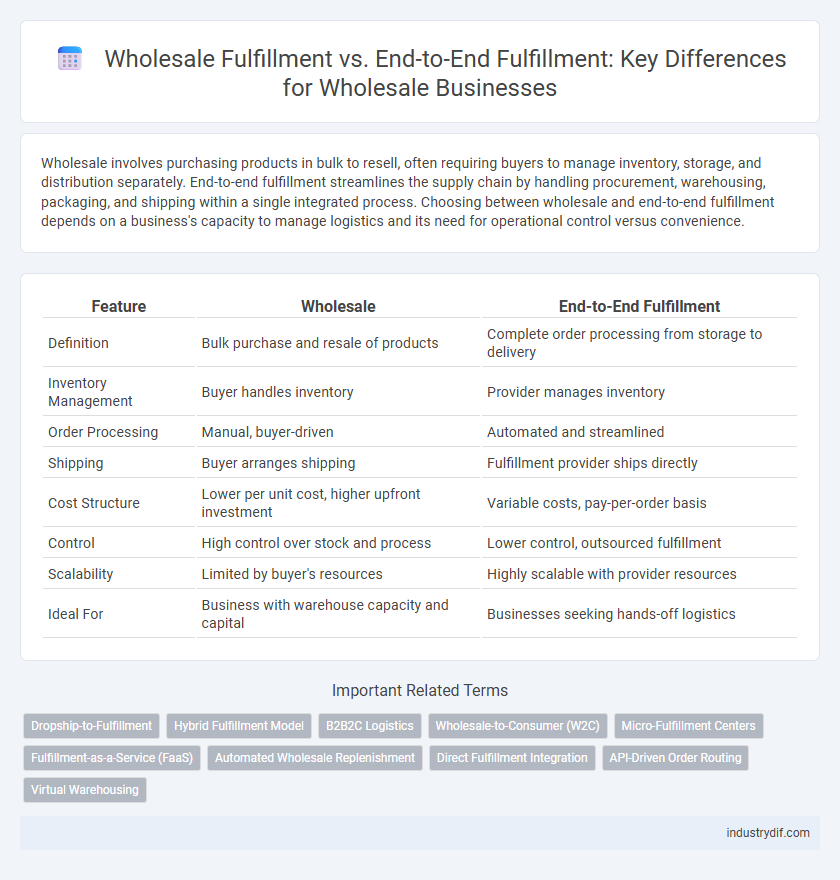

Wholesale involves purchasing products in bulk to resell, often requiring buyers to manage inventory, storage, and distribution separately. End-to-end fulfillment streamlines the supply chain by handling procurement, warehousing, packaging, and shipping within a single integrated process. Choosing between wholesale and end-to-end fulfillment depends on a business's capacity to manage logistics and its need for operational control versus convenience.

Table of Comparison

| Feature | Wholesale | End-to-End Fulfillment |

|---|---|---|

| Definition | Bulk purchase and resale of products | Complete order processing from storage to delivery |

| Inventory Management | Buyer handles inventory | Provider manages inventory |

| Order Processing | Manual, buyer-driven | Automated and streamlined |

| Shipping | Buyer arranges shipping | Fulfillment provider ships directly |

| Cost Structure | Lower per unit cost, higher upfront investment | Variable costs, pay-per-order basis |

| Control | High control over stock and process | Lower control, outsourced fulfillment |

| Scalability | Limited by buyer's resources | Highly scalable with provider resources |

| Ideal For | Business with warehouse capacity and capital | Businesses seeking hands-off logistics |

Understanding Wholesale: Definitions and Key Concepts

Wholesale involves selling goods in large quantities directly to retailers, businesses, or professional users, enabling bulk purchasing at discounted prices. It plays a crucial role in the supply chain by acting as an intermediary that bridges manufacturers and retailers, facilitating efficient distribution. Key concepts include bulk pricing, volume discounts, and minimum order quantities, which differentiate wholesale from retail and end-to-end fulfillment processes.

What is End-to-End Fulfillment?

End-to-end fulfillment is a comprehensive supply chain solution that manages every stage from order processing and inventory management to packaging and delivery directly to the customer. Unlike traditional wholesale, which primarily focuses on bulk product sales to retailers, end-to-end fulfillment ensures seamless integration of warehousing, shipping, and returns, enhancing efficiency and customer satisfaction. This approach leverages advanced logistics technology and real-time data to optimize inventory levels and reduce delivery times across multiple sales channels.

Core Differences Between Wholesale and End-to-End Fulfillment

Wholesale involves bulk purchasing and distribution of products to retailers or businesses, emphasizing inventory management and cost-effective large-scale transactions. End-to-end fulfillment encompasses the entire supply chain process, from order receipt and inventory storage to packaging and direct delivery to the end customer, focusing on seamless operational integration and customer experience. The core difference lies in wholesale prioritizing volume sales to intermediaries, whereas end-to-end fulfillment centers on efficient, customer-focused order fulfillment across multiple stages.

Inventory Management in Wholesale vs End-to-End Fulfillment

Wholesale inventory management involves maintaining large stock quantities to meet bulk order demands, requiring robust warehousing and consistent stock replenishment strategies. End-to-end fulfillment integrates inventory tracking with order processing and shipping, using real-time data analytics to optimize stock levels and reduce carrying costs. Efficient inventory control in wholesale emphasizes volume and distribution, while end-to-end fulfillment prioritizes accuracy and speed through seamless inventory synchronization across the supply chain.

Supply Chain Visibility and Control: Wholesale vs End-to-End Fulfillment

Wholesale provides broader supply chain visibility by managing bulk inventory across multiple distribution points, enabling efficient demand forecasting and reducing stockouts. End-to-end fulfillment offers granular control over every stage, from procurement to last-mile delivery, ensuring real-time tracking and enhanced transparency. This comprehensive oversight minimizes delays and optimizes inventory turnover, crucial for agile and responsive supply chain management.

Cost Structures: Comparing Wholesale and End-to-End Fulfillment

Wholesale cost structures typically involve bulk purchasing discounts and lower per-unit expenses, enabling businesses to manage inventory upfront with reduced product acquisition costs. End-to-end fulfillment integrates warehousing, packaging, and shipping, often leading to higher operational expenses but offering streamlined logistics and reduced handling fees. Comparing both, wholesale prioritizes lower upfront product costs while end-to-end fulfillment emphasizes operational efficiency and enhanced service delivery.

Scalability and Flexibility in Wholesale and End-to-End Fulfillment

Wholesale offers scalability through bulk purchasing and inventory management, enabling businesses to handle large order volumes efficiently. End-to-end fulfillment provides flexibility by integrating order processing, warehousing, and shipping, allowing rapid adaptation to market changes and customer demands. Combining wholesale scalability with end-to-end fulfillment's operational flexibility enhances overall supply chain performance and customer satisfaction.

Technology Integration: Wholesale Supply Chains vs Fulfillment Solutions

Wholesale supply chains rely on traditional inventory management systems that focus on bulk order processing, whereas end-to-end fulfillment solutions leverage advanced technology integration such as AI-driven demand forecasting, real-time tracking, and automated warehouse robotics. The seamless connection between order placement, inventory updates, and delivery logistics in fulfillment solutions enhances operational efficiency and reduces errors compared to the segmented approach in wholesale. Integrating cloud-based platforms and APIs enables fulfillment providers to offer scalable, flexible responses to market fluctuations unlike conventional wholesale systems.

Choosing the Right Model: Factors to Consider

Choosing the right fulfillment model involves evaluating order volume, customer expectations, and operational complexity. Wholesale fulfillment excels in handling bulk shipments and minimizing costs per unit, while end-to-end fulfillment offers greater control over inventory, packaging, and delivery speed. Businesses must balance cost-efficiency, scalability, and customer experience to determine which model aligns best with their growth strategy.

Wholesale vs End-to-End Fulfillment: Which Fits Your Business?

Wholesale offers bulk purchasing at reduced costs, ideal for businesses seeking scalable inventory without handling individual orders. End-to-end fulfillment integrates inventory management, packaging, and shipping, streamlining operations for businesses prioritizing efficiency and customer experience. Choosing between wholesale and end-to-end fulfillment depends on your business model, order volume, and resource allocation preferences.

Related Important Terms

Dropship-to-Fulfillment

Dropship-to-fulfillment streamlines wholesale operations by directly shipping products from suppliers to customers, reducing inventory costs and enhancing delivery speed compared to traditional end-to-end fulfillment models. This approach leverages supplier networks and real-time order processing to optimize supply chain efficiency and scalability in wholesale distribution.

Hybrid Fulfillment Model

The hybrid fulfillment model combines wholesale bulk inventory with end-to-end fulfillment processes, enabling faster delivery and improved inventory management while maintaining cost efficiency. By integrating wholesale sourcing and direct-to-customer logistics, businesses optimize supply chain agility and enhance customer satisfaction.

B2B2C Logistics

Wholesale involves bulk purchasing and distribution primarily to retailers, while end-to-end fulfillment in B2B2C logistics integrates inventory management, order processing, and delivery directly to the consumer. Efficient B2B2C logistics solutions streamline the supply chain by combining wholesale scale benefits with personalized consumer delivery, enhancing speed and reducing costs.

Wholesale-to-Consumer (W2C)

Wholesale-to-Consumer (W2C) models streamline product distribution by enabling wholesalers to sell directly to end customers, bypassing traditional retail intermediaries and reducing lead times. This approach enhances control over pricing, inventory management, and customer experience compared to End-to-End Fulfillment, which often involves multiple stakeholders and extended supply chains.

Micro-Fulfillment Centers

Micro-fulfillment centers enhance wholesale operations by enabling faster, localized inventory storage and order processing, reducing delivery times compared to traditional end-to-end fulfillment models. These compact facilities optimize inventory management and improve scalability, meeting increasing consumer demand for rapid order fulfillment in wholesale distribution.

Fulfillment-as-a-Service (FaaS)

Fulfillment-as-a-Service (FaaS) transforms wholesale operations by integrating advanced logistics, order management, and scalable warehousing into a seamless end-to-end fulfillment solution. FaaS enhances efficiency, reduces overhead, and improves delivery speed compared to traditional wholesale models, enabling businesses to better meet dynamic consumer demand.

Automated Wholesale Replenishment

Automated wholesale replenishment streamlines inventory management by integrating real-time sales data with supply chain systems, reducing stockouts and excess inventory. Unlike end-to-end fulfillment, this process emphasizes bulk product restocking from manufacturers directly to wholesalers, enhancing order accuracy and turnaround time.

Direct Fulfillment Integration

Direct fulfillment integration streamlines the supply chain by enabling wholesalers to ship products directly from manufacturers to customers, reducing inventory holding costs and delivery times. This approach enhances efficiency compared to traditional end-to-end fulfillment, which involves multiple handling stages and warehouses, leading to slower order processing and higher operational expenses.

API-Driven Order Routing

API-driven order routing in wholesale streamlines inventory management by automatically directing orders to the most optimal warehouse or supplier based on real-time data, reducing delivery times and costs. This contrasts with end-to-end fulfillment, where the entire supply chain is managed under one system, limiting flexibility and scalability in multi-vendor environments.

Virtual Warehousing

Virtual warehousing in wholesale enables businesses to streamline inventory management by integrating multiple suppliers' stock into a single, centralized system, reducing overhead costs and enhancing delivery speed. This contrasts with end-to-end fulfillment, where companies control the entire supply chain but face higher capital investment and less flexibility in scaling operations.

Wholesale vs End-to-End Fulfillment Infographic

industrydif.com

industrydif.com