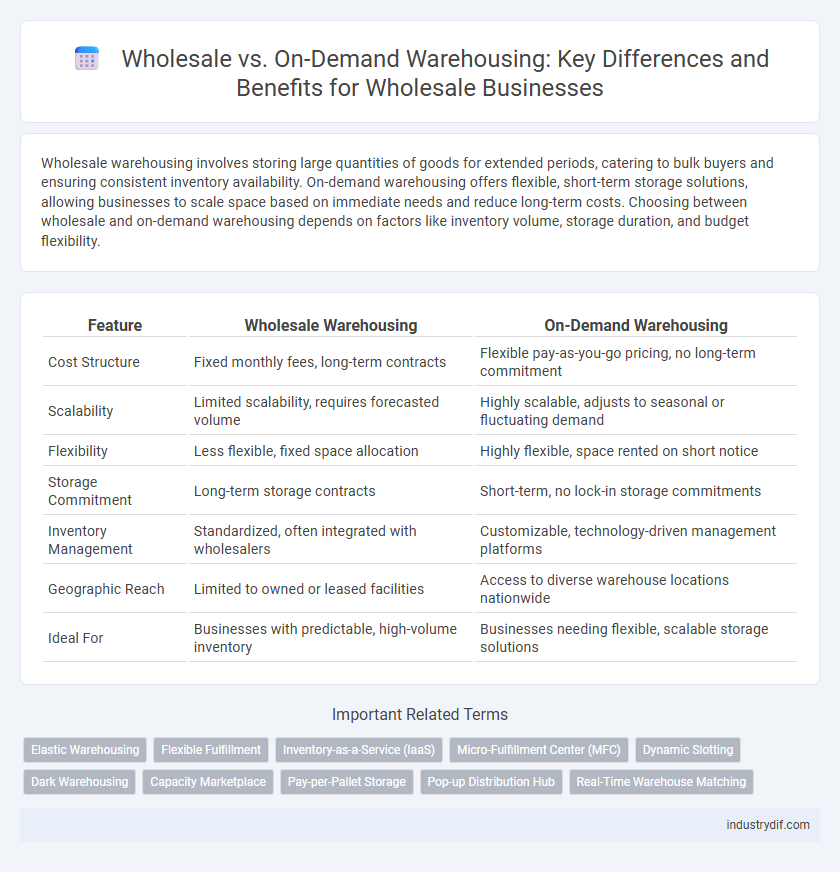

Wholesale warehousing involves storing large quantities of goods for extended periods, catering to bulk buyers and ensuring consistent inventory availability. On-demand warehousing offers flexible, short-term storage solutions, allowing businesses to scale space based on immediate needs and reduce long-term costs. Choosing between wholesale and on-demand warehousing depends on factors like inventory volume, storage duration, and budget flexibility.

Table of Comparison

| Feature | Wholesale Warehousing | On-Demand Warehousing |

|---|---|---|

| Cost Structure | Fixed monthly fees, long-term contracts | Flexible pay-as-you-go pricing, no long-term commitment |

| Scalability | Limited scalability, requires forecasted volume | Highly scalable, adjusts to seasonal or fluctuating demand |

| Flexibility | Less flexible, fixed space allocation | Highly flexible, space rented on short notice |

| Storage Commitment | Long-term storage contracts | Short-term, no lock-in storage commitments |

| Inventory Management | Standardized, often integrated with wholesalers | Customizable, technology-driven management platforms |

| Geographic Reach | Limited to owned or leased facilities | Access to diverse warehouse locations nationwide |

| Ideal For | Businesses with predictable, high-volume inventory | Businesses needing flexible, scalable storage solutions |

Understanding Wholesale and On-Demand Warehousing

Wholesale warehousing involves storing large quantities of inventory purchased in bulk to meet consistent demand, optimizing cost-efficiency and supply chain stability. On-demand warehousing offers flexible storage solutions, allowing businesses to rent space as needed, reducing overhead and adapting quickly to fluctuating inventory levels. Understanding these models helps companies balance fixed costs with scalability in their logistics strategies.

Key Differences Between Wholesale and On-Demand Warehousing

Wholesale warehousing involves long-term storage agreements with fixed costs, optimized for large inventory volumes and consistent supply chain demands. On-demand warehousing offers flexible, short-term storage solutions with variable pricing, ideal for fluctuating inventory levels and seasonal peaks. Key differences include cost structure, contract duration, and scalability tailored to business inventory turnover and market dynamics.

Scalability: Comparing Wholesale and On-Demand Models

Wholesale warehousing offers scalability through long-term leases and bulk storage capacity, enabling businesses to handle high-volume inventory with consistent space allocation. On-demand warehousing provides flexible scalability by allowing companies to adjust storage space dynamically based on real-time needs, reducing fixed costs and minimizing unused capacity. Companies choosing between wholesale and on-demand warehouses must evaluate their inventory turnover rates, seasonality, and budget constraints to select the optimal scalable solution.

Cost Efficiency in Wholesale vs On-Demand Warehousing

Wholesale warehousing offers significant cost efficiency through bulk storage rates and long-term contracts that lower per-unit expenses, making it ideal for businesses with consistent inventory demands. On-demand warehousing incurs variable costs based on short-term storage and flexible space usage, leading to higher expenses per unit during peak periods or irregular volume spikes. Companies prioritizing predictable budgeting and large volume storage often find wholesale warehousing more financially advantageous compared to the fluctuating costs of on-demand solutions.

Flexibility and Customization Options

Wholesale warehousing typically offers limited flexibility due to bulk storage commitments and predefined inventory cycles, whereas on-demand warehousing provides scalable space and customizable solutions tailored to fluctuating business needs. On-demand models allow real-time adjustments in storage capacity and service options, optimizing operational efficiency and reducing costs associated with excess inventory. Businesses seeking adaptive logistics often prefer on-demand warehousing for its ability to accommodate seasonal spikes and dynamic supply chain requirements.

Inventory Management Strategies

Wholesale inventory management relies on bulk purchasing and storage, optimizing cost efficiency through large-scale stockholding in dedicated warehouses. On-demand warehousing offers flexible, scalable storage solutions, enabling real-time inventory adjustments based on fluctuating demand and minimizing holding costs. Integrating wholesale and on-demand strategies enhances supply chain responsiveness and reduces excess inventory risks.

Technology Integration in Warehousing Solutions

Wholesale warehousing leverages advanced technology integration such as warehouse management systems (WMS), automation, and IoT sensors to optimize inventory control, streamline bulk storage, and enhance supply chain visibility. On-demand warehousing platforms utilize cloud-based software and real-time data analytics to offer scalable, flexible storage solutions, allowing businesses to adjust capacity quickly and reduce costs. The seamless integration of robotics, AI, and telematics in both models drives operational efficiency, but wholesale warehousing typically emphasizes long-term infrastructure investments, while on-demand solutions prioritize agile, technology-driven resource allocation.

Suitability for Different Business Types

Wholesale warehousing suits businesses with high-volume, consistent inventory needs, offering cost efficiency through bulk storage and long-term contracts. On-demand warehousing benefits companies with fluctuating inventory levels or seasonal products by providing flexible, scalable storage solutions without long-term commitments. E-commerce startups and seasonal retailers often prefer on-demand models, while large manufacturers and distributors typically rely on traditional wholesale warehousing for stability.

Challenges and Risks of Each Warehousing Model

Wholesale warehousing faces challenges such as high inventory holding costs, inflexibility in storage capacity, and potential obsolescence due to bulk purchasing. On-demand warehousing carries risks including variable pricing, limited control over warehouse operations, and dependency on third-party providers for timely inventory management. Both models require careful assessment of demand forecasting accuracy and supply chain variability to mitigate operational disruptions.

Deciding the Best Fit: Wholesale vs On-Demand Warehousing

Wholesale warehousing offers fixed, long-term storage solutions ideal for businesses with consistent inventory turnover and predictable demand patterns, maximizing cost efficiency through bulk storage. On-demand warehousing provides flexible, scalable space ideal for seasonal peaks or fluctuating inventory levels, enabling businesses to optimize storage costs without long-term commitments. Evaluating order volume, supply chain variability, and budget constraints helps determine whether wholesale or on-demand warehousing best aligns with a company's operational needs.

Related Important Terms

Elastic Warehousing

Elastic warehousing offers scalable storage solutions that adapt in real-time to fluctuating inventory demands, unlike traditional wholesale warehousing which relies on fixed, long-term space commitments. This on-demand flexibility reduces overhead costs and improves supply chain responsiveness by allowing businesses to expand or contract warehouse usage based on current market needs.

Flexible Fulfillment

Wholesale warehouses prioritize bulk storage with fixed contracts, limiting flexibility in order fulfillment, whereas on-demand warehousing offers scalable space and adaptable logistics to meet fluctuating demand. This flexible fulfillment approach reduces holding costs and accelerates delivery times by enabling real-time inventory management and dynamic resource allocation.

Inventory-as-a-Service (IaaS)

Wholesale distribution relies on bulk inventory storage to streamline supply chains, while On-Demand Warehousing, under the Inventory-as-a-Service (IaaS) model, offers flexible, scalable storage solutions that optimize inventory management and reduce costs. IaaS integrates real-time data analytics and dynamic space allocation to enhance operational efficiency and meet fluctuating market demands.

Micro-Fulfillment Center (MFC)

Wholesale distribution relies on bulk inventory storage and long-term contracts, while On-Demand Warehousing emphasizes flexible, short-term space usage ideal for Micro-Fulfillment Centers (MFCs) that optimize rapid order processing and local delivery. MFCs leverage on-demand warehousing to reduce last-mile delivery time and adapt quickly to fluctuating demand without the overhead of traditional wholesale inventory management.

Dynamic Slotting

Dynamic slotting in wholesale warehousing optimizes inventory placement by continuously analyzing demand patterns and product velocity, enhancing space utilization and reducing picking time. On-demand warehousing lacks this real-time adaptability, often resulting in less efficient storage and slower order fulfillment.

Dark Warehousing

Dark warehousing in wholesale refers to the operation of fully automated storage facilities without on-site staff, optimizing inventory management and reducing labor costs. This approach contrasts with on-demand warehousing, where space is rented as needed and human oversight is essential, often leading to higher operational expenses and less consistent inventory control.

Capacity Marketplace

Wholesale warehouses offer dedicated, long-term storage solutions with fixed capacity, enabling predictable inventory management and cost efficiency. On-Demand Warehousing leverages a capacity marketplace model, connecting businesses with flexible storage providers to optimize space utilization and scale warehouse capacity dynamically based on fluctuating demand.

Pay-per-Pallet Storage

Pay-per-pallet storage in wholesale warehousing offers flexible, cost-efficient solutions by charging only for the actual space used, optimizing inventory management and reducing overhead compared to traditional on-demand warehousing fees. This model maximizes cash flow by eliminating long-term commitments and enables scalable storage based on real-time demand fluctuations.

Pop-up Distribution Hub

Wholesale operations benefit from pop-up distribution hubs by enabling rapid, flexible inventory management and localized product availability without long-term storage commitments. On-demand warehousing complements wholesale by providing scalable space solutions that accommodate fluctuating order volumes, optimizing supply chain efficiency and reducing overhead costs.

Real-Time Warehouse Matching

Real-time warehouse matching in wholesale optimizes inventory distribution by instantly connecting large-volume storage demands with suitable warehouse spaces, enhancing efficiency and reducing downtime. This contrasts with on-demand warehousing, which offers flexible, short-term solutions but may lack the scalability and immediacy required for wholesale operations.

Wholesale vs On-Demand Warehousing Infographic

industrydif.com

industrydif.com