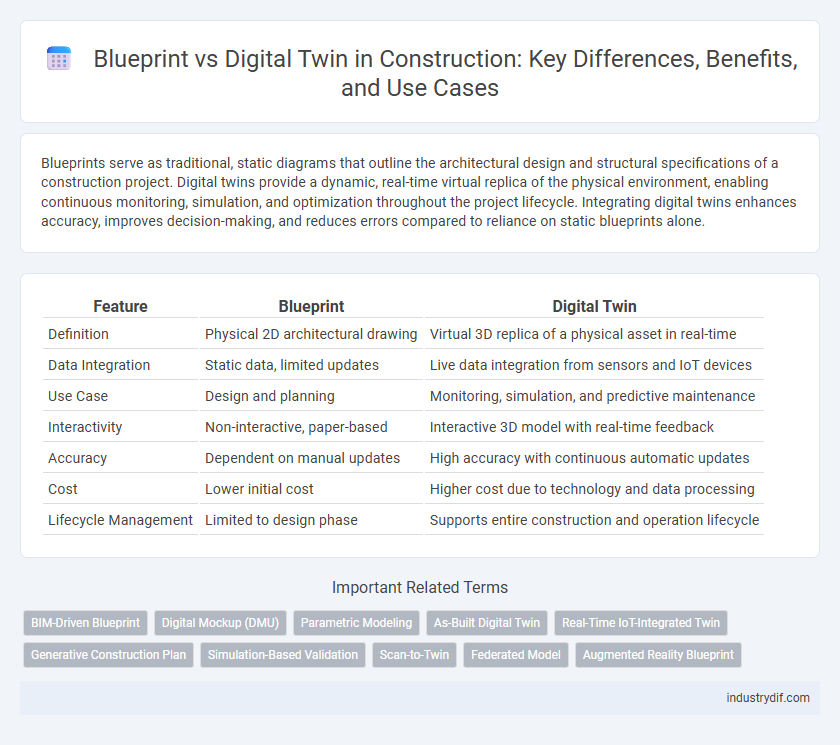

Blueprints serve as traditional, static diagrams that outline the architectural design and structural specifications of a construction project. Digital twins provide a dynamic, real-time virtual replica of the physical environment, enabling continuous monitoring, simulation, and optimization throughout the project lifecycle. Integrating digital twins enhances accuracy, improves decision-making, and reduces errors compared to reliance on static blueprints alone.

Table of Comparison

| Feature | Blueprint | Digital Twin |

|---|---|---|

| Definition | Physical 2D architectural drawing | Virtual 3D replica of a physical asset in real-time |

| Data Integration | Static data, limited updates | Live data integration from sensors and IoT devices |

| Use Case | Design and planning | Monitoring, simulation, and predictive maintenance |

| Interactivity | Non-interactive, paper-based | Interactive 3D model with real-time feedback |

| Accuracy | Dependent on manual updates | High accuracy with continuous automatic updates |

| Cost | Lower initial cost | Higher cost due to technology and data processing |

| Lifecycle Management | Limited to design phase | Supports entire construction and operation lifecycle |

Understanding Blueprints in Construction

Blueprints in construction serve as detailed technical drawings that outline the design, dimensions, and specifications of a building project, providing a clear visual guide for contractors and engineers. These traditional documents capture structural elements, electrical layouts, and plumbing systems with precise annotations, essential for accurate site execution. While blueprints focus on static representations, they remain a fundamental tool for interpreting architectural intent before integrating advanced technologies like digital twins.

Introduction to Digital Twins

Digital twins are advanced virtual replicas of physical construction assets that enable real-time monitoring and predictive analysis throughout a project's lifecycle. Unlike traditional blueprints, digital twins integrate data from IoT sensors, BIM models, and project management software to provide dynamic, data-driven insights for improved decision-making and risk management. This technology enhances construction efficiency by allowing stakeholders to visualize, simulate, and optimize processes before and during execution.

Key Differences between Blueprints and Digital Twins

Blueprints provide static, detailed architectural plans outlining the physical dimensions and specifications of a construction project, serving as traditional guides for builders. Digital twins offer dynamic, real-time virtual replicas of constructed environments, integrating IoT sensors and data analytics to monitor performance and predict maintenance needs. The primary difference lies in blueprints being fixed design documents, while digital twins enable continuous interaction, simulation, and operational management throughout the building lifecycle.

Evolution from Blueprints to Digital Twins

Blueprints served as static, two-dimensional representations of construction projects, providing essential design details and structural plans. The evolution to digital twins involves integrating real-time data with 3D models to create dynamic, interactive simulations that improve project monitoring and decision-making. Digital twins enable precise asset management, predictive maintenance, and enhanced collaboration throughout the construction lifecycle.

Advantages of Blueprints in Construction Projects

Blueprints in construction projects offer precise and standardized technical drawings that facilitate clear communication among architects, engineers, and builders. Their tangible format ensures easy accessibility on-site without the need for electronic devices or power, streamlining real-time decision-making and modifications. Blueprints also provide a durable, low-cost documentation method that supports compliance with building codes and regulatory requirements.

Benefits of Digital Twins for Modern Construction

Digital twins enhance modern construction by providing real-time, data-driven insights that improve project accuracy and reduce costly errors. They enable precise modeling of building performance, allowing for proactive maintenance and optimized resource management throughout the lifecycle. Integration of digital twins with IoT sensors and BIM systems accelerates decision-making, promotes sustainability, and increases overall efficiency on construction sites.

Challenges of Adopting Digital Twins

Adopting digital twins in construction faces significant challenges such as high initial costs for hardware and software integration, complex data management from diverse sources, and the need for skilled personnel to interpret real-time analytics. Additionally, interoperability issues arise when integrating digital twins with existing legacy systems and traditional blueprints, causing delays and increased project risks. Security concerns over sensitive project data and ongoing maintenance requirements further complicate widespread adoption in the construction industry.

Integration of Digital Twins with BIM Technology

Digital Twins integrated with Building Information Modeling (BIM) technology enable real-time data synchronization between physical assets and their virtual models, enhancing project visualization and decision-making. This integration supports comprehensive lifecycle management by continuously updating the digital replica with actual site performance, which surpasses the static nature of traditional blueprints. Leveraging IoT sensors and BIM data interoperability accelerates facility maintenance, reduces operational costs, and improves construction accuracy.

Real-life Applications: Blueprints vs Digital Twins

Blueprints serve as traditional, static representations of construction plans essential for on-site reference and regulatory approvals, ensuring precise measurement and structure alignment. Digital twins offer dynamic, real-time simulations and data integration of physical buildings, enabling predictive maintenance, performance optimization, and enhanced collaboration across stakeholders. The integration of digital twins in construction projects significantly reduces errors and operational costs compared to reliance solely on blueprints.

The Future of Construction: Digital Transformation

Digital Twins represent the future of construction by providing real-time, data-driven models that enhance project visualization, risk management, and operational efficiency far beyond traditional blueprints. Unlike static blueprints, Digital Twins integrate IoT sensors and BIM data to simulate construction processes, enabling predictive maintenance and dynamic decision-making throughout a project's lifecycle. This digital transformation accelerates project delivery timelines, minimizes costly errors, and supports sustainable building practices through continuous monitoring and optimization.

Related Important Terms

BIM-Driven Blueprint

BIM-driven blueprints offer a comprehensive digital representation of a building's physical and functional characteristics, providing precise project specifications and facilitating coordinated workflows. Unlike traditional blueprints, BIM integrates real-time data and enables dynamic updates, enhancing collaboration and reducing construction errors.

Digital Mockup (DMU)

Digital Mockup (DMU) in construction offers a comprehensive 3D visualization and simulation of building components, enabling real-time collaboration and error detection before physical construction begins. Unlike traditional blueprints, DMUs facilitate dynamic modifications and integration of complex systems, significantly enhancing project accuracy and efficiency.

Parametric Modeling

Parametric modeling in construction leverages digital twin technology to create dynamic, data-rich representations of physical assets that can be continuously updated and analyzed, contrasting with static blueprints that offer fixed, two-dimensional designs. Digital twins enable real-time simulation and optimization of building performance, facilitating enhanced decision-making and lifecycle management beyond traditional blueprint limitations.

As-Built Digital Twin

As-Built Digital Twins provide an accurate, real-time 3D representation of a constructed facility, capturing precise conditions and modifications made during construction, unlike traditional blueprints that offer static, 2D design plans. By integrating IoT sensors and BIM data, As-Built Digital Twins enable proactive maintenance, improved asset management, and enhanced decision-making throughout the building lifecycle.

Real-Time IoT-Integrated Twin

Real-time IoT-integrated digital twins provide dynamic, data-driven models that mirror construction site conditions instantaneously, enabling predictive maintenance and enhanced project management. Unlike static blueprints, these digital twins leverage sensor data to optimize workflows, reduce risks, and improve overall construction efficiency.

Generative Construction Plan

A Generative Construction Plan leverages Digital Twin technology to create precise, real-time simulations that enhance project accuracy beyond traditional blueprints. This approach integrates data-driven models to optimize resource allocation, reduce errors, and streamline construction workflows for improved efficiency.

Simulation-Based Validation

Blueprints provide static, 2D representations of construction projects, limiting the ability to perform dynamic analysis and real-time adjustments. Digital twins enable simulation-based validation by creating interactive, 3D virtual models that replicate physical assets and construction processes, allowing for predictive analytics, scenario testing, and optimized project outcomes.

Scan-to-Twin

Blueprints provide static, two-dimensional plans for construction projects, while Digital Twins offer dynamic, real-time 3D models that update as physical conditions change. The Scan-to-Twin process captures precise laser scans of buildings to create accurate digital replicas, enhancing project monitoring, facility management, and predictive maintenance in construction.

Federated Model

A Federated Model integrates multiple specialized digital twins into a unified framework, enabling real-time data synchronization and comprehensive project visualization beyond static blueprints. Unlike traditional blueprints that offer fixed design documentation, the Federated Model supports dynamic collaboration, enhancing precision in construction planning, monitoring, and facility management.

Augmented Reality Blueprint

Augmented Reality blueprints enhance construction accuracy by overlaying 3D digital models onto physical sites, enabling real-time visualization and interactive project modifications. This integration streamlines collaboration, reduces errors, and accelerates decision-making compared to traditional blueprints and static digital twin models.

Blueprint vs Digital Twin Infographic

industrydif.com

industrydif.com