Site visits provide firsthand sensory evaluation and immediate problem-solving capabilities, allowing construction teams to assess real-time conditions and address unexpected issues on the ground. Digital twin monitoring offers continuous, data-driven insights through virtual simulations, enabling detailed analysis of project progress and predictive maintenance without physical presence. Combining both methods optimizes project management by leveraging the accuracy of on-site inspections with the efficiency and scalability of digital technologies.

Table of Comparison

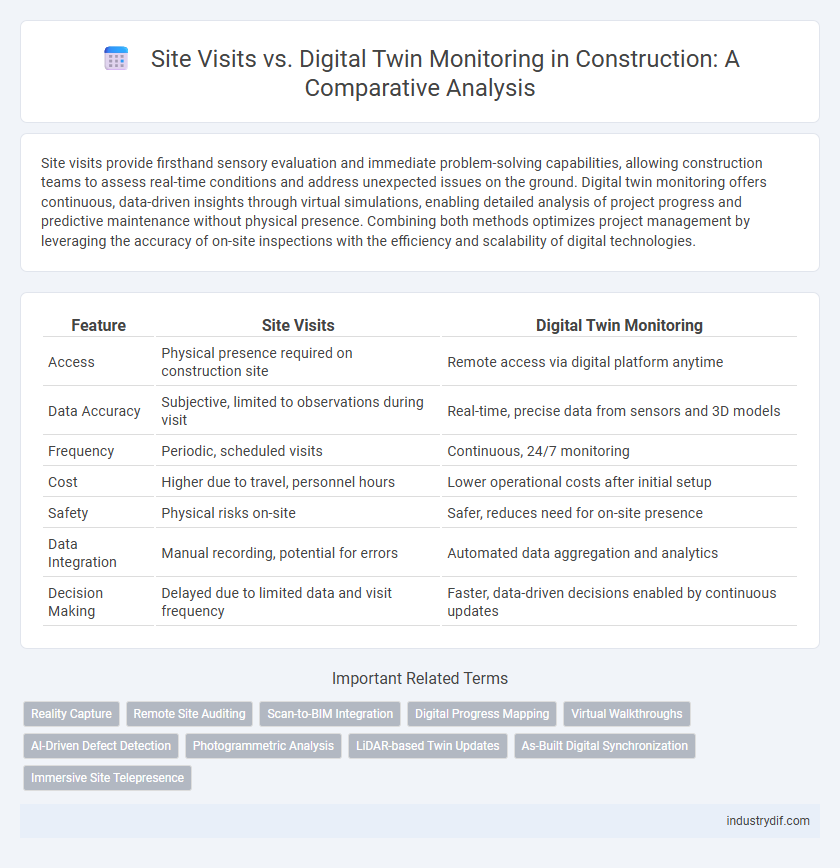

| Feature | Site Visits | Digital Twin Monitoring |

|---|---|---|

| Access | Physical presence required on construction site | Remote access via digital platform anytime |

| Data Accuracy | Subjective, limited to observations during visit | Real-time, precise data from sensors and 3D models |

| Frequency | Periodic, scheduled visits | Continuous, 24/7 monitoring |

| Cost | Higher due to travel, personnel hours | Lower operational costs after initial setup |

| Safety | Physical risks on-site | Safer, reduces need for on-site presence |

| Data Integration | Manual recording, potential for errors | Automated data aggregation and analytics |

| Decision Making | Delayed due to limited data and visit frequency | Faster, data-driven decisions enabled by continuous updates |

Introduction to Site Visits and Digital Twin Monitoring

Site visits provide direct, on-the-ground assessment of construction progress, allowing for real-time observation of materials, labor, and environmental conditions. Digital twin monitoring uses a virtual replica of the construction site to track project metrics, analyze structural integrity, and optimize workflows through data integration from IoT sensors and BIM models. Combining physical site visits with digital twin technology enhances accuracy in project management and risk mitigation.

Key Differences Between Site Visits and Digital Twin Monitoring

Site visits provide physical inspection and real-time human assessment of construction progress, safety, and quality, whereas digital twin monitoring offers continuous remote tracking through real-time data integration and 3D modeling. Site visits are limited by accessibility, weather, and time constraints, while digital twins enable predictive analytics and immediate issue detection by synchronizing sensor data with virtual models. The key differences lie in the manual, on-site verification of conditions versus automated, data-driven insights enhancing decision-making and operational efficiency.

Benefits of Traditional Site Visits in Construction

Traditional site visits in construction provide direct, real-time insight into project progress, allowing for immediate identification and resolution of issues such as structural defects or safety hazards. On-site presence fosters better communication among stakeholders, enabling hands-on inspections and dynamic problem-solving that digital twin monitoring may miss. Physical visits also ensure compliance with regulatory standards through thorough visual assessments that complement digital data analysis.

Advantages of Digital Twin Monitoring Technology

Digital twin monitoring technology provides real-time data analytics, enabling precise tracking of construction site progress and immediate identification of potential issues. It enhances safety by allowing remote observation and virtual inspections, reducing the need for physical presence in hazardous environments. Integration with IoT sensors and BIM models improves project efficiency, minimizing delays and optimizing resource allocation throughout the construction lifecycle.

Challenges of On-Site Inspections

On-site inspections face challenges such as limited accessibility to hazardous or remote areas and inconsistent data collection caused by human error. Physical site visits often disrupt ongoing construction activities, causing delays and increased labor costs. Digital twin monitoring overcomes these limitations by providing real-time, accurate data and enhancing remote collaboration for improved project management.

Limitations of Digital Twin Monitoring Solutions

Digital twin monitoring solutions in construction face limitations such as incomplete data capture due to sensor placement gaps and challenges in replicating real-time environmental changes accurately. These systems often struggle with latency issues and may not account for unexpected on-site variables like human activity or equipment malfunctions. Reliance on digital twins without regular physical site visits can lead to overlooked safety hazards and inaccuracies in project progress assessments.

Impact on Project Timelines and Efficiency

Site visits provide on-the-ground verification and real-time issue resolution, crucial for immediate problem-solving and ensuring quality control during construction. Digital twin monitoring offers continuous, data-driven insights and predictive analytics, enabling proactive maintenance and reducing the likelihood of delays by simulating project progress virtually. Integrating both methods enhances project timelines and efficiency by combining accurate physical inspections with advanced digital oversight.

Role of Data Accuracy in Both Methods

Data accuracy is crucial in site visits and digital twin monitoring within construction, impacting decision-making and project outcomes. In site visits, precise data collection relies on human observation and manual measurements, which can introduce errors and inconsistencies. Digital twin monitoring leverages real-time sensor data and advanced analytics to provide accurate, up-to-date representations of construction sites, enhancing predictive maintenance and risk management through continuous, reliable data streams.

Cost Comparison: Site Visits vs Digital Twin Monitoring

Site visits incur higher costs due to travel expenses, labor hours, and potential delays, often ranging from hundreds to thousands of dollars per visit depending on project size and location. Digital twin monitoring significantly reduces these expenses by enabling continuous, real-time remote inspections with minimal manpower, lowering operational costs by up to 40%. Implementing digital twin technology also minimizes downtime and enhances resource allocation, providing better cost efficiency in construction project management.

Future Trends in Construction Monitoring Technologies

Future trends in construction monitoring technologies emphasize the integration of digital twin monitoring with traditional site visits to enhance real-time data accuracy and predictive analytics. Advanced sensors, IoT devices, and BIM models enable continuous virtual monitoring, reducing the need for frequent physical inspections while ensuring safety and project efficiency. This hybrid approach leverages AI-driven insights to streamline construction management and optimize resource allocation on-site.

Related Important Terms

Reality Capture

Reality capture in construction leverages advanced technologies like 3D laser scanning and photogrammetry to create precise digital twins, enabling continuous site monitoring without physical presence. Digital twin monitoring enhances project accuracy and efficiency by providing real-time data updates, reducing the need for frequent site visits and minimizing human error.

Remote Site Auditing

Remote site auditing through digital twin monitoring enhances real-time data access, enabling precise assessments without the need for physical presence, reducing travel costs and project delays. Site visits remain crucial for tactile inspections and context-specific judgments but are increasingly supplemented by digital twins for continuous monitoring and risk management.

Scan-to-BIM Integration

Scan-to-BIM integration enhances site visits by enabling real-time digital twin monitoring, which improves accuracy in capturing as-built conditions and streamlines project management. This technology reduces the need for frequent physical inspections, accelerates decision-making processes, and facilitates seamless collaboration among construction stakeholders.

Digital Progress Mapping

Digital Twin Monitoring enables real-time digital progress mapping by integrating IoT sensors and 3D models, providing accurate, up-to-date site conditions without physical presence. This technology reduces the need for frequent site visits, streamlines decision-making, and enhances project timeline tracking through precise virtual monitoring.

Virtual Walkthroughs

Virtual walkthroughs enabled by digital twin monitoring offer immersive, real-time visualization of construction sites, enhancing project oversight without the need for physical presence. This technology reduces travel costs, accelerates decision-making, and improves collaboration by providing stakeholders with precise, up-to-date site conditions remotely.

AI-Driven Defect Detection

AI-driven defect detection in construction site visits leverages machine learning algorithms to identify structural issues with high accuracy and real-time insights. Digital twin monitoring enhances this process by continuously analyzing data from 3D models and IoT sensors, enabling predictive maintenance and reducing costly delays.

Photogrammetric Analysis

Photogrammetric analysis enhances site visits by providing precise 3D models through high-resolution images, enabling detailed monitoring without physical presence. Integrating digital twin monitoring with photogrammetry accelerates progress tracking and improves accuracy in construction project management.

LiDAR-based Twin Updates

LiDAR-based digital twin monitoring provides real-time, high-precision 3D mapping of construction sites, enabling continuous progress tracking and early detection of discrepancies without the need for frequent physical site visits. This technology enhances project efficiency by reducing manual inspection errors and optimizing decision-making through accurate, up-to-date virtual representations.

As-Built Digital Synchronization

Site visits enable direct inspection and real-time adjustments of construction progress, ensuring accurate as-built conditions, while digital twin monitoring integrates sensor data for continuous, remote updates of project status. As-built digital synchronization bridges these approaches by aligning physical site changes with virtual models, enhancing precision in construction management and reducing costly discrepancies.

Immersive Site Telepresence

Immersive site telepresence, enabled by digital twin monitoring, offers real-time, 3D visualization of construction sites, significantly reducing the need for physical site visits and enhancing project oversight. This technology integrates IoT sensors and high-resolution imaging to provide stakeholders with immersive, interactive access to site conditions, improving decision-making and reducing delays.

Site Visits vs Digital Twin Monitoring Infographic

industrydif.com

industrydif.com