Concrete is a widely used construction material known for its strength and durability, but it can develop cracks over time due to environmental stress and wear. Self-healing concrete enhances traditional concrete by incorporating healing agents that activate when cracks appear, automatically sealing and restoring structural integrity. This innovation reduces maintenance costs and extends the lifespan of concrete structures, making it a sustainable choice for modern construction projects.

Table of Comparison

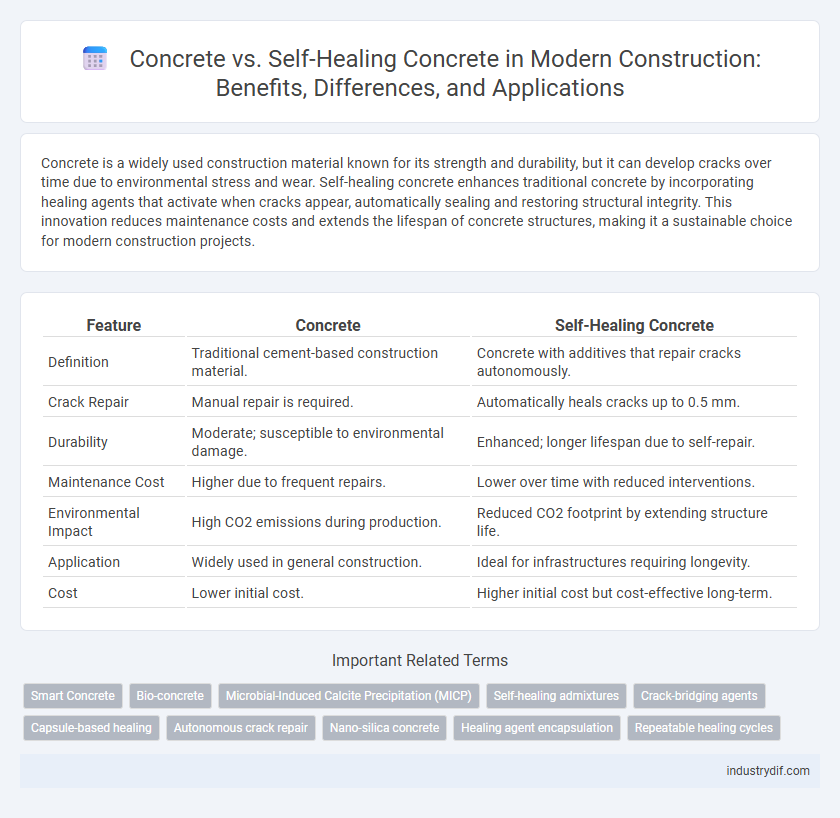

| Feature | Concrete | Self-Healing Concrete |

|---|---|---|

| Definition | Traditional cement-based construction material. | Concrete with additives that repair cracks autonomously. |

| Crack Repair | Manual repair is required. | Automatically heals cracks up to 0.5 mm. |

| Durability | Moderate; susceptible to environmental damage. | Enhanced; longer lifespan due to self-repair. |

| Maintenance Cost | Higher due to frequent repairs. | Lower over time with reduced interventions. |

| Environmental Impact | High CO2 emissions during production. | Reduced CO2 footprint by extending structure life. |

| Application | Widely used in general construction. | Ideal for infrastructures requiring longevity. |

| Cost | Lower initial cost. | Higher initial cost but cost-effective long-term. |

Introduction to Concrete and Self-Healing Concrete

Concrete, a composite material composed of cement, aggregates, water, and admixtures, is widely used in construction due to its strength, durability, and versatility. Self-healing concrete incorporates special additives such as bacteria or microcapsules containing healing agents that activate upon damage, enabling the material to autonomously repair cracks and extend structural lifespan. This innovation addresses common concrete weaknesses by enhancing durability and reducing maintenance costs in infrastructure projects.

Composition Differences between Traditional and Self-Healing Concrete

Traditional concrete comprises cement, water, aggregates, and chemical admixtures, forming a rigid matrix prone to cracks over time. Self-healing concrete integrates specialized bacteria or encapsulated healing agents within the mixture, triggering crack repair through biomineralization or chemical reactions when damage occurs. This innovative composition enhances durability by autonomously sealing microcracks, reducing maintenance costs and extending structural lifespan.

How Self-Healing Concrete Works

Self-healing concrete incorporates microcapsules or bacteria that activate upon crack formation, releasing healing agents to fill and seal fissures. This innovative material mimics natural biological processes by producing calcium carbonate, which bonds the cracked areas and restores structural integrity. The autonomous repair mechanism significantly extends the lifespan of concrete structures while reducing maintenance costs and environmental impacts.

Strength and Durability Comparison

Traditional concrete exhibits high compressive strength but tends to develop microcracks over time, compromising durability and requiring regular maintenance. Self-healing concrete incorporates bacteria or chemical agents that autonomously repair microcracks, significantly enhancing longevity and reducing structural degradation. This innovative material not only maintains comparable initial strength but also offers superior durability by preventing crack propagation and extending service life in construction applications.

Cost Implications in Construction Projects

Concrete remains the most cost-effective material in construction projects due to its widespread availability and established production methods, with typical costs ranging between $100 to $150 per cubic meter. Self-healing concrete, incorporating specialized bacteria or capsules for crack repair, can increase initial expenses by 20-50%, but offers significant long-term savings by reducing maintenance and extending structural lifespan. Investing in self-healing concrete can lower lifecycle costs, particularly in infrastructure projects where durability and reduced repair frequency are critical.

Environmental Impact and Sustainability

Concrete production accounts for approximately 8% of global CO2 emissions, posing significant environmental challenges due to energy-intensive cement manufacturing. Self-healing concrete incorporates bacteria or encapsulated healing agents that autonomously repair cracks, extending the lifespan of structures and reducing maintenance-related material consumption. This innovation enhances sustainability by minimizing resource extraction, lowering carbon footprints, and promoting resilience in infrastructure.

Maintenance and Lifecycle Considerations

Concrete requires regular maintenance to address cracks and structural degradation, leading to increased lifecycle costs and potential downtime. Self-healing concrete significantly reduces maintenance needs by autonomously repairing microcracks, extending the material's lifespan and enhancing durability. This innovation lowers long-term expenses and improves safety in infrastructure projects by preventing early-stage damage progression.

Typical Applications in Modern Construction

Concrete is widely used in foundational structures, pavements, bridges, and high-rise buildings due to its high compressive strength and durability. Self-healing concrete enhances longevity in infrastructure projects such as tunnels, marine structures, and critical transportation networks by autonomously repairing micro-cracks and reducing maintenance costs. This innovation improves structural resilience and sustainability in modern construction practices, extending service life and minimizing environmental impact.

Limitations and Challenges of Each Material

Traditional concrete faces challenges such as cracking from shrinkage, environmental degradation, and limited durability, often requiring costly repairs and maintenance. Self-healing concrete, while promising enhanced longevity and crack repair through microbial or encapsulated healing agents, grapples with high production costs, complex formulation processes, and uncertain long-term performance in diverse environmental conditions. Both materials demand careful consideration of structural requirements, environmental impact, and economic feasibility to determine optimal application in construction projects.

Future Trends in Concrete Technology

Future trends in concrete technology emphasize the integration of self-healing concrete to enhance durability and reduce maintenance costs in construction projects. Self-healing concrete utilizes embedded microcapsules or bacteria that activate upon cracking to seal fissures autonomously, significantly extending the service life of infrastructure. Innovations in nanotechnology and biomimicry are driving advancements, positioning self-healing materials as a sustainable solution to traditional concrete's vulnerability to environmental stressors.

Related Important Terms

Smart Concrete

Smart concrete, often referred to as self-healing concrete, incorporates microcapsules or bacteria that activate upon crack formation, significantly extending the durability and lifespan of structures in construction. This innovative material reduces maintenance costs and environmental impact by autonomously repairing damages, making it a superior alternative to traditional concrete in smart infrastructure development.

Bio-concrete

Bio-concrete, a form of self-healing concrete, incorporates bacteria that produce limestone to fill cracks autonomously, significantly extending the durability and reducing maintenance costs compared to traditional concrete. This innovative material enhances structural integrity by preventing water ingress and corrosion, making it a sustainable solution for infrastructure with improved longevity and environmental benefits.

Microbial-Induced Calcite Precipitation (MICP)

Concrete strengthened with Microbial-Induced Calcite Precipitation (MICP) exhibits enhanced durability by autonomously filling cracks through calcite deposition, reducing maintenance costs and extending structural lifespan. Unlike traditional concrete, self-healing concrete using MICP leverages bacteria to trigger mineral precipitation, resulting in improved resistance to water ingress and structural degradation.

Self-healing admixtures

Self-healing concrete incorporates advanced self-healing admixtures such as bacteria-based agents and microcapsules containing healing agents that activate upon cracking, significantly enhancing durability and reducing maintenance costs. These admixtures enable autonomous crack repair by precipitating calcium carbonate or releasing polymers, which restores structural integrity and extends the lifespan of concrete infrastructure.

Crack-bridging agents

Concrete relies on traditional crack-bridging agents such as steel fibers and polymer additives to enhance structural integrity by controlling crack propagation. Self-healing concrete incorporates innovative microcapsules or bacterial agents that autonomously repair cracks, reducing maintenance costs and extending the lifespan of construction materials.

Capsule-based healing

Capsule-based self-healing concrete incorporates microcapsules filled with healing agents that release upon crack formation, effectively restoring structural integrity and preventing further deterioration. This innovative technology enhances durability and reduces maintenance costs compared to traditional concrete by autonomously repairing micro-cracks and extending service life.

Autonomous crack repair

Self-healing concrete autonomously repairs micro-cracks through embedded capsules or bacteria that precipitate calcium carbonate, enhancing durability compared to traditional concrete which requires manual maintenance. This innovative technology significantly reduces structural degradation and maintenance costs by automatically sealing fissures and preventing water infiltration.

Nano-silica concrete

Nano-silica concrete enhances traditional concrete by improving durability and strength through the incorporation of nanoscale silica particles that fill microvoids, reducing permeability and crack formation. In contrast, self-healing concrete uses microcapsules or bacteria to autonomously repair cracks, while nano-silica concrete primarily focuses on nano-modification to increase density and mechanical performance, offering a complementary approach to structural longevity.

Healing agent encapsulation

Encapsulation of healing agents in self-healing concrete involves embedding microcapsules containing adhesives or bacteria that activate upon cracking, enabling autonomous repair and prolonging structural durability. In contrast, traditional concrete lacks these embedded systems, making it prone to irreversible damage and increased maintenance costs over time.

Repeatable healing cycles

Self-healing concrete incorporates microcapsules or bacteria that enable multiple repeatable healing cycles by autonomously repairing cracks, significantly extending the lifespan of structures compared to traditional concrete, which lacks this regenerative capability and requires manual repairs. This durability enhancement reduces maintenance costs and improves structural integrity in infrastructure subjected to frequent stress and environmental exposure.

Concrete vs Self-Healing Concrete Infographic

industrydif.com

industrydif.com