On-site inspection provides real-time, physical assessment of construction progress and quality, allowing for immediate issue identification and direct communication with the team. Digital twin inspection leverages virtual replicas of the construction site, enabling remote monitoring, predictive analysis, and enhanced data integration for smarter decision-making. Combining both methods optimizes accuracy and efficiency, ensuring projects meet safety standards and performance expectations.

Table of Comparison

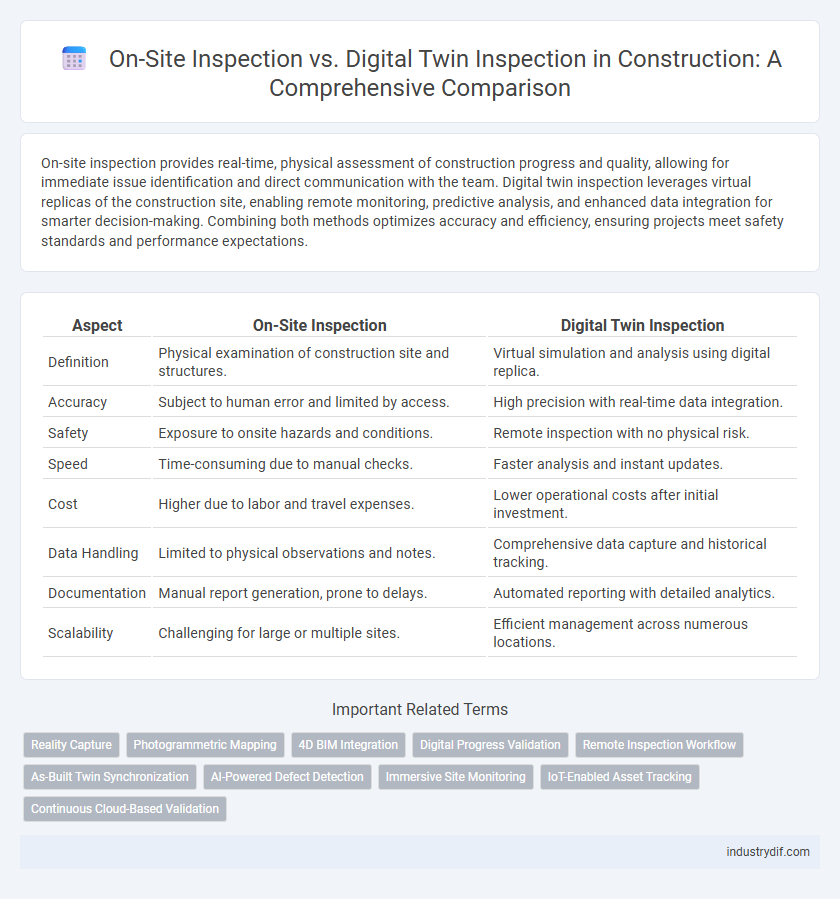

| Aspect | On-Site Inspection | Digital Twin Inspection |

|---|---|---|

| Definition | Physical examination of construction site and structures. | Virtual simulation and analysis using digital replica. |

| Accuracy | Subject to human error and limited by access. | High precision with real-time data integration. |

| Safety | Exposure to onsite hazards and conditions. | Remote inspection with no physical risk. |

| Speed | Time-consuming due to manual checks. | Faster analysis and instant updates. |

| Cost | Higher due to labor and travel expenses. | Lower operational costs after initial investment. |

| Data Handling | Limited to physical observations and notes. | Comprehensive data capture and historical tracking. |

| Documentation | Manual report generation, prone to delays. | Automated reporting with detailed analytics. |

| Scalability | Challenging for large or multiple sites. | Efficient management across numerous locations. |

Introduction to On-Site Inspection and Digital Twin Inspection

On-site inspection involves physically examining construction sites to assess structural integrity, safety compliance, and project progress through direct observation and manual measurements. Digital twin inspection uses highly detailed, real-time 3D models and sensor data to simulate and monitor construction environments remotely, enabling predictive maintenance and enhanced decision-making. Combining both methods improves accuracy and efficiency in construction quality control and risk management.

Defining On-Site Inspections in Construction

On-site inspections in construction involve physical visits to the project site to assess the quality, safety, and compliance of work with blueprints and regulations. Inspectors observe structural elements, materials, and workmanship firsthand, enabling immediate identification of defects or deviations. This traditional approach ensures real-time validation but can be limited by accessibility and human error.

Understanding Digital Twin Technology in Construction

Digital twin technology in construction enables the creation of accurate virtual replicas of physical sites, allowing continuous monitoring and real-time data analysis. Unlike traditional on-site inspections that rely on manual observations, digital twins integrate IoT sensors, BIM models, and AI to predict potential issues and optimize project workflows. This technology enhances decision-making by providing detailed insights into structural performance, safety compliance, and resource management throughout the project lifecycle.

Key Differences Between On-Site and Digital Twin Inspections

On-site inspections require physical presence to assess construction progress, identify defects, and ensure compliance with safety standards, whereas digital twin inspections utilize real-time 3D models and sensor data to remotely monitor structural integrity and project status. On-site methods often face limitations like weather constraints and accessibility issues, while digital twins enable continuous, data-driven analysis and predictive maintenance without disrupting construction activities. The integration of IoT devices in digital twin inspections significantly enhances accuracy and efficiency compared to traditional manual assessments.

Advantages of On-Site Inspections

On-site inspections in construction provide real-time, tactile assessments of structural integrity and material quality that digital twins cannot fully replicate. Direct visual and physical evaluations enable immediate identification of issues such as cracks, alignment errors, or safety hazards, ensuring compliance with building codes and standards. Moreover, on-site inspections foster clear communication among contractors, engineers, and inspectors, accelerating decision-making and reducing costly project delays.

Benefits of Digital Twin Inspection Methods

Digital Twin Inspection methods provide precise, real-time data visualization that enhances accuracy and reduces human error during construction assessments. These methods enable remote monitoring, streamline project management, and support predictive maintenance by simulating potential issues before they occur on site. Integrating digital twins accelerates decision-making processes and improves overall construction quality while minimizing downtime and cost overruns.

Challenges and Limitations of On-Site Inspections

On-site inspections in construction face challenges such as limited access to hazardous or confined spaces, potential safety risks, and time-consuming manual data collection. Human error during visual assessments can lead to missed defects or inaccurate measurements, impacting project quality and timelines. The inability to capture real-time data often results in delayed decision-making and increased costs compared to digital twin inspections.

Limitations and Considerations for Digital Twin Inspections

Digital Twin Inspections in construction face limitations such as dependency on high-quality data input and real-time sensor accuracy, which can affect the fidelity of virtual replicas. Considerations include the requirement of advanced technology infrastructure and skilled personnel to interpret digital models accurately. Unlike traditional On-Site Inspections, Digital Twins may miss nuanced physical defects, emphasizing the need for integrated hybrid inspection approaches.

Integration of On-Site and Digital Twin Inspection Processes

Integrating on-site inspection with digital twin inspection processes enhances construction project accuracy and efficiency by enabling real-time data synchronization and comprehensive analysis. The combined approach allows seamless cross-referencing of physical site conditions with digital models, facilitating proactive issue detection and decision-making. This integration supports continuous monitoring, reducing errors, minimizing rework, and accelerating project timelines.

Future Trends in Construction Inspection Technologies

Construction inspection is rapidly evolving with the integration of digital twin technology, enabling real-time monitoring and predictive maintenance that surpass traditional on-site inspections. Future trends emphasize augmented reality (AR), artificial intelligence (AI), and Internet of Things (IoT) sensors embedded within digital twins to enhance accuracy, reduce human error, and facilitate remote collaboration. These advancements are expected to significantly improve project timelines, safety standards, and cost efficiency in the construction industry.

Related Important Terms

Reality Capture

On-site inspection relies on physical presence to assess construction progress and identify defects, providing real-time, tactile feedback but limited by accessibility and human error. Digital twin inspection leverages reality capture technologies like 3D scanning and photogrammetry to create precise virtual models, enabling detailed remote analysis, progress tracking, and clash detection with higher accuracy and efficiency.

Photogrammetric Mapping

Photogrammetric mapping enhances on-site inspection accuracy by generating detailed 3D models from photographic data, enabling precise measurements and visual analysis. Digital twin inspection leverages this data to create real-time, interactive virtual replicas of construction sites, improving monitoring, issue detection, and project management efficiency.

4D BIM Integration

On-site inspection provides real-time, physical verification of construction progress, while digital twin inspection leverages 4D BIM integration to simulate and analyze project timelines, spatial data, and resource allocation in a virtual environment. Integrating 4D BIM with digital twins enhances predictive analytics, reduces risks, and improves decision-making accuracy compared to traditional manual inspection methods.

Digital Progress Validation

Digital Twin Inspection enables real-time, precise validation of construction progress by continuously comparing as-built conditions with design models, reducing errors and delays. On-site inspections, while traditional, often lack the detailed data integration and immediate feedback that digital twins provide for progress tracking and decision-making.

Remote Inspection Workflow

Remote inspection workflow in construction leverages digital twin technology to create accurate virtual replicas of physical sites, enabling real-time monitoring and issue detection without the need for on-site presence. This approach enhances efficiency, reduces travel costs, and facilitates immediate stakeholder collaboration while maintaining detailed, up-to-date project data.

As-Built Twin Synchronization

On-site inspection provides real-time, physical verification of construction elements, ensuring immediate identification of discrepancies between design and actual build. Digital Twin Inspection with As-Built Twin Synchronization enables continuous, accurate updates by integrating sensor data and 3D models, enhancing remote monitoring and predictive maintenance throughout the project lifecycle.

AI-Powered Defect Detection

AI-powered defect detection enhances on-site inspection by rapidly identifying structural issues through advanced imaging and machine learning algorithms, reducing human error and inspection time. Digital twin inspection integrates AI with real-time data from the physical site to simulate and predict potential defects, enabling proactive maintenance and precise decision-making.

Immersive Site Monitoring

Immersive site monitoring through digital twin inspection enhances real-time data visualization and accuracy, enabling virtual walkthroughs that detect discrepancies and potential hazards without physical presence. Traditional on-site inspections rely on manual observation prone to human error and limited access, whereas digital twin technology integrates IoT sensors, 3D modeling, and AI analytics to offer comprehensive, continuous project oversight.

IoT-Enabled Asset Tracking

IoT-enabled asset tracking enhances on-site inspection by providing real-time data and location updates, increasing efficiency and reducing manual errors. Digital twin inspection leverages this IoT data to create accurate virtual replicas of assets, enabling predictive maintenance and remote monitoring for improved decision-making in construction projects.

Continuous Cloud-Based Validation

Continuous cloud-based validation enables real-time monitoring and instant data synchronization for both on-site inspections and digital twin inspections, significantly enhancing accuracy and efficiency in construction project management. Digital twin inspection leverages this technology to provide a dynamic, virtual replica updated continuously, while on-site inspection relies on periodic physical assessments supported by cloud data integration.

On-Site Inspection vs Digital Twin Inspection Infographic

industrydif.com

industrydif.com