Laser levels provide quick and accurate horizontal and vertical alignment ideal for simpler construction tasks, while robotic total stations offer advanced precision and automation for complex surveying and layout projects. Total stations integrate electronic distance measurement and angle calculations, streamlining workflow with remote operation capabilities. Choosing between the two depends on project complexity, required accuracy, and budget constraints.

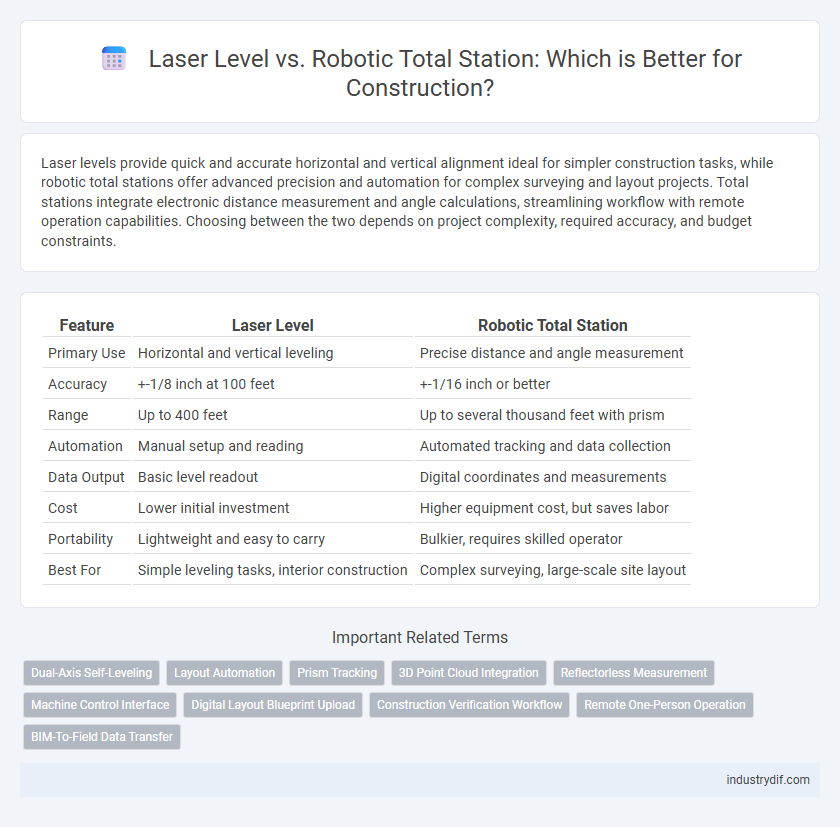

Table of Comparison

| Feature | Laser Level | Robotic Total Station |

|---|---|---|

| Primary Use | Horizontal and vertical leveling | Precise distance and angle measurement |

| Accuracy | +-1/8 inch at 100 feet | +-1/16 inch or better |

| Range | Up to 400 feet | Up to several thousand feet with prism |

| Automation | Manual setup and reading | Automated tracking and data collection |

| Data Output | Basic level readout | Digital coordinates and measurements |

| Cost | Lower initial investment | Higher equipment cost, but saves labor |

| Portability | Lightweight and easy to carry | Bulkier, requires skilled operator |

| Best For | Simple leveling tasks, interior construction | Complex surveying, large-scale site layout |

Introduction to Laser Levels and Robotic Total Stations

Laser levels project highly visible laser beams to create accurate horizontal and vertical reference lines, essential for aligning and leveling tasks in construction. Robotic total stations combine electronic distance measurement with automated surveying capabilities, offering precise 3D measurements and remote control functionality. Both instruments enhance accuracy and efficiency in site layout, though robotic total stations provide advanced data collection and positioning versatility.

Key Features of Laser Levels

Laser levels provide accurate horizontal and vertical leveling with self-leveling capabilities, ensuring precise alignment for construction tasks like framing and foundation work. They emit a highly visible laser beam, simplifying layout over short to medium distances, typically up to 100 meters. Their portability and ease of use make them ideal for site work requiring quick, repetitive measurements.

Key Features of Robotic Total Stations

Robotic Total Stations feature advanced automated surveying technology with integrated electronic distance measurement (EDM) and motorized prism tracking, enabling one-person operation and enhanced precision on construction sites. Equipped with onboard software and remote control capabilities, they provide real-time data collection and allow for efficient layout and measurement of complex structures. These instruments offer superior accuracy over traditional laser levels, making them ideal for detailed topographic surveys, building construction, and infrastructure projects.

Accuracy Comparison: Laser Levels vs Robotic Total Stations

Robotic Total Stations offer superior accuracy compared to traditional laser levels by integrating electronic distance measurement with precise angular data capture, achieving millimeter-level precision ideal for high-stakes construction projects. Laser levels provide adequate accuracy for basic leveling and alignment tasks, typically within a few millimeters over short distances, but lack the detailed positional data that robotic total stations deliver. For complex site layouts requiring exact coordinates and automated measurements, robotic total stations outperform laser levels in minimizing human error and enhancing project precision.

Ease of Use and Setup Differences

Laser levels offer straightforward setup with simple calibration and quick deployment, making them ideal for basic leveling tasks. Robotic total stations require more complex initial setup involving precise instrument calibration and programmed surveying points, suited for detailed site measurements. While laser levels prioritize speed and simplicity, robotic total stations deliver higher accuracy but demand more technical expertise during installation and operation.

Cost Comparison and ROI Analysis

Laser levels typically cost between $100 and $700, making them a budget-friendly option for basic leveling tasks on construction sites. Robotic total stations, priced from $10,000 to over $50,000, represent a significant upfront investment but offer advanced features like automated measurements and data integration, enhancing precision and reducing labor costs. The return on investment for robotic total stations is substantial in large-scale, complex projects due to time savings and improved accuracy, whereas laser levels provide faster ROI in smaller, less complex jobs with limited precision requirements.

Applications in Construction Projects

Laser levels provide precise horizontal and vertical alignment ideal for interior construction tasks such as framing, drywall installation, and leveling foundations. Robotic total stations offer advanced surveying capabilities with automated angle and distance measurements, making them essential for large-scale site layout, topographic surveys, and infrastructure projects. Combining both tools enhances accuracy and efficiency across various construction phases, from initial site planning to final structural alignments.

Productivity and Time Savings

Laser levels provide quick and accurate reference points for horizontal and vertical alignment, significantly speeding up layout tasks on construction sites. Robotic total stations enhance productivity by automating angle and distance measurements, allowing a single operator to perform complex surveying with high precision. Combining these tools can reduce project timeframes by minimizing manual errors and improving workflow efficiency in construction surveying and layout.

Integration with Construction Technology

Laser levels offer precise horizontal and vertical alignment, seamlessly integrating with BIM software for real-time site adjustments, enhancing project accuracy. Robotic total stations combine advanced surveying capabilities with GPS and data transfer technologies, enabling automated measurements and immediate updates to construction management platforms. The integration of these tools with construction technology accelerates workflows, reduces errors, and improves coordination across excavation, foundation, and layout tasks.

Choosing the Right Tool for Your Construction Needs

Selecting the right tool between a laser level and a robotic total station depends on the precision and scope of your construction project. Laser levels provide quick, accurate leveling and alignment for smaller tasks, while robotic total stations offer advanced surveying capabilities with high accuracy for large-scale projects. Prioritize project size, required measurement precision, and budget to ensure optimal tool performance and efficiency.

Related Important Terms

Dual-Axis Self-Leveling

Laser levels with dual-axis self-leveling provide quick and accurate horizontal and vertical alignment crucial for foundation and framing work, ensuring minimal setup time and high precision on uneven surfaces. Robotic total stations incorporate dual-axis compensation to maintain exact positioning during complex measurements and automated site layout, enhancing accuracy in large-scale construction projects.

Layout Automation

Laser levels provide precise horizontal and vertical reference lines for quick, cost-effective layout tasks, while robotic total stations offer advanced automation by integrating distance measurement and angular data for highly accurate 3D positioning and complex site layouts. Robotic total stations enhance construction layout automation through remote operation and real-time data feedback, significantly reducing human error and labor time compared to traditional laser levels.

Prism Tracking

Laser levels provide accurate horizontal and vertical plane measurements but lack the advanced prism tracking capabilities found in robotic total stations, which automatically follow a prism target for real-time positioning and enhanced precision. Robotic total stations enable continuous, hands-free measurement on complex construction sites, improving efficiency and reducing the potential for human error compared to manual laser level setups.

3D Point Cloud Integration

Laser levels provide accurate horizontal and vertical reference lines ideal for basic layout tasks, while robotic total stations offer advanced 3D point cloud integration, enabling precise spatial data capture and real-time surveying on construction sites. The integration of 3D point clouds with robotic total stations enhances BIM workflows, improves site monitoring, and accelerates project execution through automated data collection and analysis.

Reflectorless Measurement

Laser levels provide accurate horizontal and vertical alignment for basic construction tasks, but robotic total stations excel with reflectorless measurement capabilities, enabling precise distance and angle data collection without requiring a prism reflector. This technology enhances efficiency and safety on complex job sites by allowing measurements of hard-to-reach or hazardous locations.

Machine Control Interface

Laser levels provide a straightforward machine control interface ideal for simple elevation and alignment tasks, ensuring quick setup and ease of use on construction sites. Robotic total stations offer advanced machine control interfaces with enhanced precision and remote operation capabilities, enabling automated data collection and real-time adjustments for complex site measurements.

Digital Layout Blueprint Upload

Laser levels provide precise horizontal and vertical reference lines ideal for simple layout tasks, while robotic total stations enable seamless digital layout blueprint uploads for highly accurate, automated site measurements and real-time data integration. Robotic total stations enhance workflow efficiency by allowing users to upload complex digital blueprints directly, reducing manual errors and accelerating project timelines on construction sites.

Construction Verification Workflow

Laser levels provide precise horizontal and vertical reference lines essential for quick alignment and leveling tasks in construction verification workflows, ensuring foundational accuracy. Robotic total stations integrate advanced angle and distance measurements with automated data capture, significantly enhancing site surveying efficiency and real-time verification accuracy for complex construction projects.

Remote One-Person Operation

A robotic total station enables remote one-person operation by integrating advanced GPS and robotic tracking technologies, allowing precise measurements and automatic adjustments without manual intervention. Laser levels, although accurate for simple leveling tasks, lack remote control capabilities and require operator presence for positioning and reading, limiting efficiency on complex construction sites.

BIM-To-Field Data Transfer

Laser levels provide precise horizontal and vertical reference points essential for layout tasks, but robotic total stations enhance BIM-to-field data transfer by enabling automated, accurate positioning tied directly to digital models. Integrating robotic total stations with BIM software accelerates construction workflows, improves accuracy in site measurements, and reduces human error compared to traditional laser level methods.

Laser Level vs Robotic Total Station Infographic

industrydif.com

industrydif.com