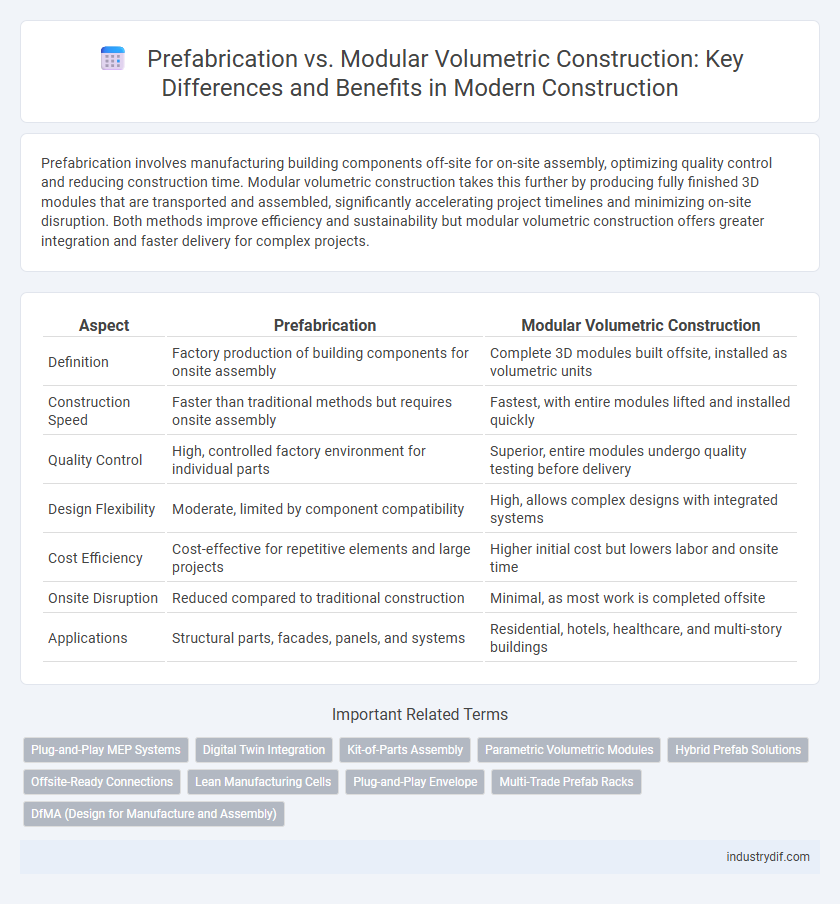

Prefabrication involves manufacturing building components off-site for on-site assembly, optimizing quality control and reducing construction time. Modular volumetric construction takes this further by producing fully finished 3D modules that are transported and assembled, significantly accelerating project timelines and minimizing on-site disruption. Both methods improve efficiency and sustainability but modular volumetric construction offers greater integration and faster delivery for complex projects.

Table of Comparison

| Aspect | Prefabrication | Modular Volumetric Construction |

|---|---|---|

| Definition | Factory production of building components for onsite assembly | Complete 3D modules built offsite, installed as volumetric units |

| Construction Speed | Faster than traditional methods but requires onsite assembly | Fastest, with entire modules lifted and installed quickly |

| Quality Control | High, controlled factory environment for individual parts | Superior, entire modules undergo quality testing before delivery |

| Design Flexibility | Moderate, limited by component compatibility | High, allows complex designs with integrated systems |

| Cost Efficiency | Cost-effective for repetitive elements and large projects | Higher initial cost but lowers labor and onsite time |

| Onsite Disruption | Reduced compared to traditional construction | Minimal, as most work is completed offsite |

| Applications | Structural parts, facades, panels, and systems | Residential, hotels, healthcare, and multi-story buildings |

Introduction to Prefabrication and Modular Volumetric Construction

Prefabrication involves manufacturing building components off-site in a controlled environment, which are then transported and assembled on-site, enhancing construction efficiency and quality control. Modular volumetric construction takes prefabrication further by producing fully integrated 3D modules, complete with internal finishes and services, allowing for faster on-site assembly and reduced labor costs. Both methods significantly minimize construction waste and disruption while improving project timelines and sustainability outcomes.

Defining Prefabrication: Methods and Applications

Prefabrication involves manufacturing building components off-site in controlled factory settings, allowing for precise quality control and reduced on-site construction time. Common methods include panelized systems, where walls and floors are pre-assembled, and volumetric units that are transported and installed as single pieces. This approach is widely applied in residential housing, commercial buildings, and infrastructure projects, enhancing efficiency and minimizing construction waste.

Understanding Modular Volumetric Construction

Modular Volumetric Construction involves manufacturing entire building units off-site in controlled factory environments, ensuring higher precision and quality control compared to traditional methods. These fully assembled volumetric modules are transported and installed on-site, significantly reducing construction time and minimizing disruptions. This approach enhances project efficiency, lowers labor costs, and supports sustainable building practices by reducing material waste.

Key Differences Between Prefabrication and Modular Volumetric Construction

Prefabrication involves manufacturing building components off-site for on-site assembly, focusing on parts like walls, floors, and roofs, while modular volumetric construction creates fully enclosed modules with finishes and services integrated. Modular volumetric offers faster project timelines due to comprehensive off-site assembly and reduced on-site labor compared to traditional prefabrication. Both methods improve quality control and reduce material waste but differ significantly in scale, complexity, and application within the construction process.

Advantages of Prefabrication in Construction Projects

Prefabrication in construction projects offers significant time savings by allowing building components to be manufactured simultaneously with site preparation, reducing overall project duration. Enhanced quality control is achieved through factory-based production, minimizing defects and ensuring consistency across all prefabricated elements. Cost efficiency is improved by reducing labor needs on-site and minimizing material waste, making prefabrication a strategic choice for large-scale construction developments.

Benefits of Modular Volumetric Construction for Efficiency

Modular volumetric construction significantly enhances efficiency by delivering fully finished, three-dimensional sections off-site, reducing on-site labor and minimizing weather-related delays. This approach ensures faster project completion with consistent quality control, as modules are fabricated in controlled factory environments. The streamlined logistics and reduced material waste also contribute to cost savings and sustainability in construction projects.

Challenges and Limitations in Prefabrication

Prefabrication faces challenges such as limited design flexibility and high transportation costs for large components, which can constrain project scope and logistics. Quality control issues may arise from variations in factory conditions, impacting overall building performance. Additionally, coordination complexities between off-site manufacturing and on-site assembly can lead to scheduling delays and increased labor requirements.

Modular Volumetric Construction: Common Barriers

Modular volumetric construction faces common barriers such as high initial capital investment and complex logistics for transporting large prefabricated units. Regulatory challenges and strict building codes often delay approvals, adding to project timelines and costs. Limited skilled workforce and resistance to adopting new methods further inhibit widespread implementation of this efficient construction technology.

Comparing Cost, Time, and Quality Outcomes

Prefabrication typically involves manufacturing building components off-site and assembling them on-site, often reducing labor costs and construction time compared to traditional methods. Modular volumetric construction, which produces fully finished volumetric units in controlled factory environments, frequently achieves higher quality control and faster project delivery due to minimized on-site work and standardized processes. Cost efficiency varies by project scale and complexity, with modular volumes generally incurring higher initial fabrication expenses offset by significant time savings and reduced rework costs.

Future Trends in Prefabrication and Modular Volumetric Construction

Future trends in prefabrication and modular volumetric construction emphasize increased automation and digital integration, enhancing precision and reducing labor costs. The adoption of Building Information Modeling (BIM) and Internet of Things (IoT) technologies enables real-time monitoring and improved collaboration across supply chains. Growing demand for sustainable and eco-friendly materials drives innovation, positioning modular methods as key solutions for efficient, scalable urban development.

Related Important Terms

Plug-and-Play MEP Systems

Plug-and-play MEP systems in modular volumetric construction enable rapid on-site installation by delivering fully integrated mechanical, electrical, and plumbing components pre-assembled within prefabricated modules. This approach reduces construction time and labor costs compared to traditional prefabrication methods that often require separate MEP installation stages, enhancing overall project efficiency and quality control.

Digital Twin Integration

Prefabrication and modular volumetric construction both benefit significantly from digital twin integration, enabling real-time simulation and optimization of building components before on-site assembly. Digital twins enhance precision in design, reduce errors, and improve project timelines by providing dynamic data analytics and virtual testing environments for prefabricated modules and volumetric units.

Kit-of-Parts Assembly

Prefabrication involves manufacturing building components in a factory for on-site assembly, emphasizing standardized kit-of-parts systems that streamline construction processes and reduce waste. Modular volumetric construction advances this by delivering complete volumetric modules, fully fitted with structural, mechanical, and finishes, enabling faster on-site assembly and superior quality control.

Parametric Volumetric Modules

Parametric volumetric modules in modular volumetric construction enhance precision and customization by using algorithm-driven design processes that optimize material usage and structural performance. Unlike traditional prefabrication, these modules allow for adaptive, flexible configurations, significantly reducing construction time and waste while improving scalability and integration with digital workflows.

Hybrid Prefab Solutions

Hybrid prefab solutions integrate the precision of modular volumetric construction with the flexibility of traditional prefabrication, optimizing project timelines and cost efficiency while maintaining high-quality standards. This approach leverages factory-built modules combined with on-site assembly, reducing waste, enhancing sustainability, and allowing tailored design adaptations in complex construction projects.

Offsite-Ready Connections

Prefabrication uses pre-assembled components transported to the site for integration, whereas modular volumetric construction delivers fully finished modules with offsite-ready connections enabling faster onsite assembly and reduced labor costs. Offsite-ready connections in modular systems enhance precision, minimize onsite errors, and improve project schedules by streamlining the joining of structural, mechanical, and electrical systems.

Lean Manufacturing Cells

Lean manufacturing cells in prefabrication optimize workflow by focusing on standardized, repetitive tasks within controlled environments, reducing waste and increasing efficiency. Modular volumetric construction integrates these lean principles by assembling entire building modules off-site, enabling faster on-site installation and minimizing construction time through improved quality control and resource management.

Plug-and-Play Envelope

Plug-and-play envelope systems in modular volumetric construction enable rapid assembly by integrating pre-fabricated wall, floor, and roof components with finished internal and external finishes, reducing on-site labor and construction time. Unlike traditional prefabrication, modular volumetric construction offers fully enclosed, factory-built units that are transported and installed as complete building sections, enhancing quality control and minimizing weather-related delays.

Multi-Trade Prefab Racks

Multi-trade prefab racks streamline construction by integrating electrical, plumbing, HVAC, and structural components into pre-assembled units, reducing on-site labor and minimizing coordination errors. Modular volumetric construction benefits from these racks through faster installation times and enhanced quality control, improving overall project efficiency and cost-effectiveness.

DfMA (Design for Manufacture and Assembly)

Prefabrication involves producing building components off-site for on-site assembly, emphasizing standardized parts, while modular volumetric construction integrates full 3D modules fabricated under controlled factory settings. DfMA optimizes both methods by enhancing design efficiency, reducing waste, and improving assembly speed, leading to cost savings and higher quality control in construction projects.

Prefabrication vs Modular Volumetric Construction Infographic

industrydif.com

industrydif.com