Traditional QA in construction relies heavily on manual inspections and physical prototypes, which can be time-consuming and prone to human error. Digital Twin QA leverages real-time data and advanced simulation models to enhance accuracy, predict potential issues, and streamline the quality assurance process. This transition enables more efficient project monitoring, reduces costly rework, and improves overall construction quality.

Table of Comparison

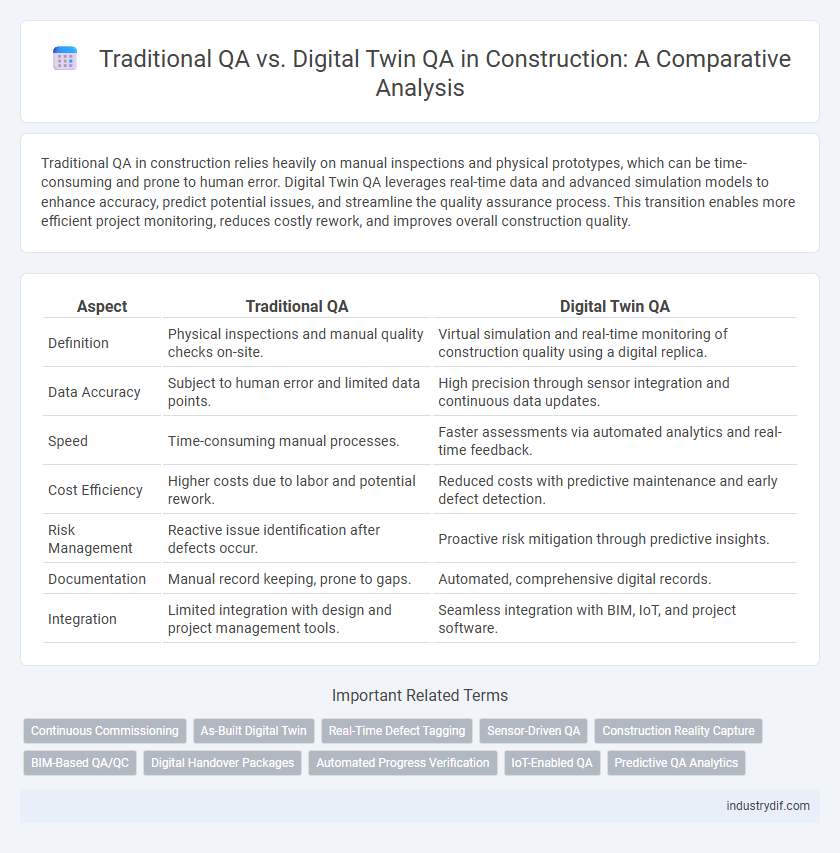

| Aspect | Traditional QA | Digital Twin QA |

|---|---|---|

| Definition | Physical inspections and manual quality checks on-site. | Virtual simulation and real-time monitoring of construction quality using a digital replica. |

| Data Accuracy | Subject to human error and limited data points. | High precision through sensor integration and continuous data updates. |

| Speed | Time-consuming manual processes. | Faster assessments via automated analytics and real-time feedback. |

| Cost Efficiency | Higher costs due to labor and potential rework. | Reduced costs with predictive maintenance and early defect detection. |

| Risk Management | Reactive issue identification after defects occur. | Proactive risk mitigation through predictive insights. |

| Documentation | Manual record keeping, prone to gaps. | Automated, comprehensive digital records. |

| Integration | Limited integration with design and project management tools. | Seamless integration with BIM, IoT, and project software. |

Introduction to Quality Assurance in Construction

Quality Assurance in construction ensures project specifications, safety standards, and regulatory compliance are consistently met. Traditional QA relies on manual inspections and documentation, often leading to delays and human errors. Digital Twin QA leverages real-time data and virtual models to enhance accuracy, predict potential issues, and streamline quality monitoring processes.

Defining Traditional QA Methods

Traditional QA methods in construction involve manual inspection, physical sampling, and documentation to ensure materials and workmanship meet project specifications. These processes rely heavily on human expertise and on-site assessments, often leading to time-consuming and error-prone quality checks. Standard techniques include visual inspections, checklists, and laboratory testing of concrete, soil, and other building materials to verify compliance with relevant standards.

Understanding Digital Twin QA

Digital Twin Quality Assurance (QA) enhances construction processes by creating a virtual replica of physical assets, enabling real-time monitoring and predictive analysis of project performance. Unlike Traditional QA, which relies on manual inspections and static data, Digital Twin QA integrates IoT sensors, BIM models, and AI algorithms to detect defects early and optimize maintenance schedules. This advanced approach reduces rework, improves safety compliance, and increases overall project efficiency through continuous data-driven insights.

Key Differences Between Traditional and Digital Twin QA

Traditional QA in construction relies on manual inspections, static data, and periodic sampling, often leading to delayed issue identification. Digital Twin QA leverages real-time data integration, continuous monitoring, and predictive analytics to enhance accuracy and proactive problem-solving. Key differences include digital twins' ability to simulate entire construction processes and environments, providing dynamic feedback that traditional methods cannot offer.

Efficiency and Accuracy in QA Processes

Traditional QA in construction relies on manual inspections and physical measurements, often leading to slower processes and potential human errors. Digital Twin QA leverages real-time data and 3D models, significantly enhancing efficiency by automating quality checks and improving accuracy through continuous monitoring. Integrating Digital Twin technology reduces rework and project delays, resulting in more precise and timely QA outcomes.

Data Collection and Analysis Techniques

Traditional QA in construction relies heavily on manual data collection methods such as visual inspections and physical measurements, which can be time-consuming and prone to human error. Digital Twin QA utilizes real-time data acquisition through IoT sensors and integrated BIM models, enabling continuous monitoring and precise analysis of construction parameters. This advanced approach enhances data accuracy, facilitates predictive maintenance, and improves overall project quality control.

Real-Time Monitoring and Issue Detection

Traditional QA in construction typically relies on periodic inspections and manual data collection, often leading to delayed issue detection and reactive problem-solving. Digital Twin QA leverages real-time monitoring through sensors and IoT integration, enabling continuous data analysis and immediate identification of defects or deviations in structural integrity. This shift enhances proactive decision-making, reduces downtime, and improves overall project quality by providing dynamic visualization of construction progress and performance metrics.

Cost Implications: Traditional vs Digital Twin QA

Traditional quality assurance (QA) in construction often leads to higher costs due to manual inspections, rework, and delayed issue detection, which can result in budget overruns. Digital Twin QA utilizes real-time data and predictive analytics to identify defects early, reducing rework and minimizing costly downtime, ultimately lowering overall project expenses. Investing in Digital Twin technology streamlines QA processes, enhances accuracy, and delivers significant cost savings compared to conventional methods.

Challenges and Limitations of Both Approaches

Traditional QA in construction faces challenges such as limited real-time data access, labor-intensive inspections, and higher susceptibility to human error, which can delay project timelines and increase costs. Digital Twin QA offers enhanced visualization and predictive analytics but is limited by high initial implementation costs, data integration complexities, and the need for specialized technical expertise. Both approaches struggle with scalability and interoperability issues, impacting their effectiveness in large, complex construction projects.

Future Trends in Construction Quality Assurance

Digital Twin QA leverages real-time data and advanced simulations to predict and mitigate construction defects before they occur, enhancing accuracy beyond Traditional QA methods. Integration of IoT sensors and AI analytics in Digital Twin models enables continuous monitoring of structural integrity and material performance throughout the project lifecycle. Future trends in construction quality assurance prioritize predictive maintenance, automated compliance verification, and smart construction site management powered by digital twin technologies.

Related Important Terms

Continuous Commissioning

Traditional QA in construction relies on periodic inspections and manual data collection, often leading to delayed issue detection and reactive problem-solving. Digital Twin QA enables continuous commissioning through real-time monitoring and automated analytics, enhancing proactive maintenance and optimizing asset performance throughout the building lifecycle.

As-Built Digital Twin

As-Built Digital Twin QA enhances traditional construction quality assurance by providing precise, real-time 3D models that capture exact conditions of the built environment, enabling early detection of deviations and reducing rework. Unlike conventional methods relying on static documentation, Digital Twin QA integrates sensor data and BIM updates to continuously monitor structural integrity and project compliance throughout the construction lifecycle.

Real-Time Defect Tagging

Traditional QA in construction relies on manual inspections and delayed reporting, which often leads to slower identification and resolution of defects. In contrast, Digital Twin QA enables real-time defect tagging by integrating IoT sensors and AI analytics, enhancing accuracy and accelerating corrective actions on site.

Sensor-Driven QA

Traditional QA in construction relies heavily on manual inspections and periodic sampling, which often leads to delayed issue detection and increased rework costs. Sensor-driven QA through Digital Twin technology enables real-time monitoring and predictive analytics, enhancing accuracy and accelerating decision-making for proactive quality management.

Construction Reality Capture

Traditional QA in construction often relies on manual inspections and 2D drawings, which can miss real-time discrepancies on-site, whereas Digital Twin QA integrates Construction Reality Capture through 3D laser scanning and IoT sensors to create precise, real-time digital replicas of the physical environment. This technology enables automated progress tracking, instant deviation detection, and improved decision-making, significantly reducing costly rework and enhancing overall project accuracy.

BIM-Based QA/QC

BIM-based QA/QC integrates real-time data and 3D models to enhance accuracy and efficiency compared to traditional QA methods, which rely heavily on manual inspections and paper-based documentation. Digital Twin QA leverages BIM to provide continuous monitoring, predictive analytics, and streamlined collaboration, significantly reducing errors and project delays in construction quality control.

Digital Handover Packages

Digital Twin QA enhances construction quality assurance by integrating real-time data and virtual models, enabling precise validation of building components before project completion. Digital Handover Packages streamline the transition process by providing comprehensive, accurate, and easily accessible documentation, reducing errors and improving facility management efficiency.

Automated Progress Verification

Traditional QA in construction often relies on manual inspections and paper-based documentation, resulting in slower progress verification and increased chances of human error. Digital Twin QA leverages real-time data integration and automated progress tracking, enabling precise, continuous monitoring and reducing project delays through enhanced accuracy and efficiency.

IoT-Enabled QA

IoT-enabled Quality Assurance in construction leverages real-time sensor data and digital twin models to monitor project parameters continuously, enhancing accuracy and reducing human error compared to traditional QA methods that rely on periodic manual inspections. This integration allows for predictive maintenance, immediate issue detection, and data-driven decision-making, significantly improving construction quality and efficiency.

Predictive QA Analytics

Traditional QA in construction relies heavily on manual inspections and historical data analysis, often resulting in reactive issue resolution with limited prediction capabilities. Digital Twin QA leverages real-time data integration and advanced predictive analytics, enabling proactive identification of potential quality risks and optimizing project outcomes through continuous monitoring and simulation.

Traditional QA vs Digital Twin QA Infographic

industrydif.com

industrydif.com