Steel rebar remains the most widely used reinforcement material in construction due to its high tensile strength and proven durability, especially in large-scale infrastructure projects. Basalt fiber reinforcement offers corrosion resistance, lightweight properties, and high chemical stability, making it ideal for harsh environments and reducing long-term maintenance costs. Choosing between steel rebar and basalt fiber depends on project requirements, environmental conditions, and budget constraints for optimized structural performance.

Table of Comparison

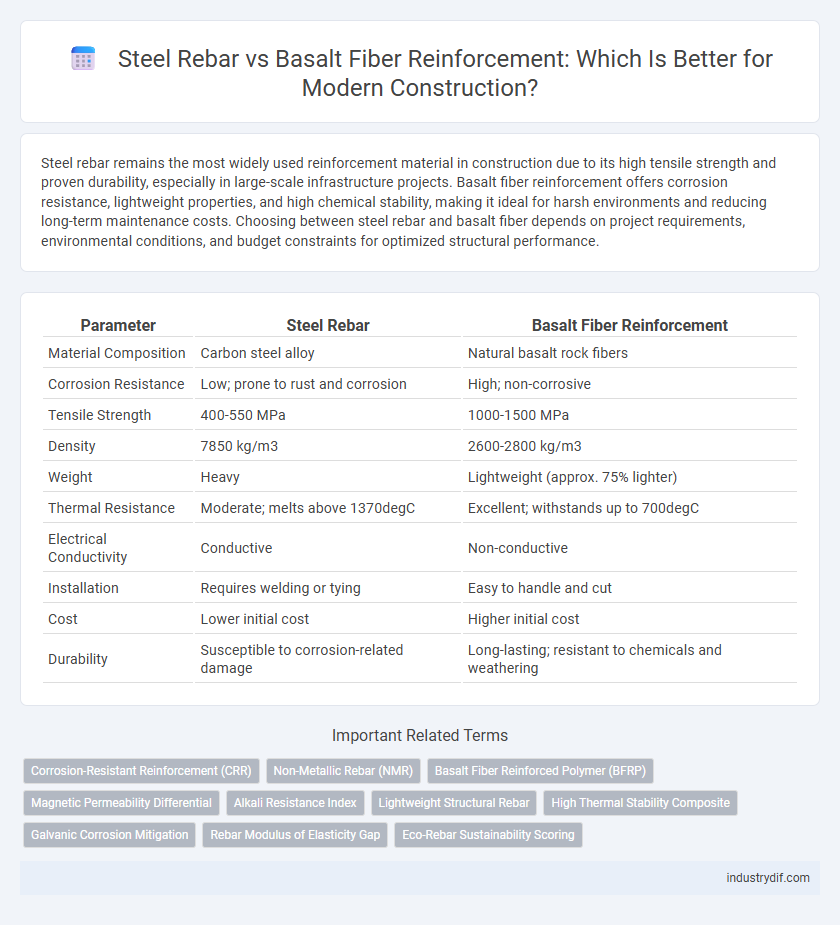

| Parameter | Steel Rebar | Basalt Fiber Reinforcement |

|---|---|---|

| Material Composition | Carbon steel alloy | Natural basalt rock fibers |

| Corrosion Resistance | Low; prone to rust and corrosion | High; non-corrosive |

| Tensile Strength | 400-550 MPa | 1000-1500 MPa |

| Density | 7850 kg/m3 | 2600-2800 kg/m3 |

| Weight | Heavy | Lightweight (approx. 75% lighter) |

| Thermal Resistance | Moderate; melts above 1370degC | Excellent; withstands up to 700degC |

| Electrical Conductivity | Conductive | Non-conductive |

| Installation | Requires welding or tying | Easy to handle and cut |

| Cost | Lower initial cost | Higher initial cost |

| Durability | Susceptible to corrosion-related damage | Long-lasting; resistant to chemicals and weathering |

Introduction to Construction Reinforcement Materials

Steel rebar remains the most widely used reinforcement material in construction due to its high tensile strength, durability, and proven performance in concrete structures. Basalt fiber reinforcement, emerging as an eco-friendly alternative, offers superior corrosion resistance and lighter weight while maintaining significant tensile strength. Both materials play crucial roles in enhancing the structural integrity and longevity of modern construction projects.

Overview of Steel Rebar in Construction

Steel rebar is the most commonly used reinforcement material in construction due to its high tensile strength, durability, and strong bond with concrete. It provides essential structural support in concrete frameworks for buildings, bridges, and infrastructure, ensuring resistance to tension and cracking. Steel rebar's widespread availability, cost-effectiveness, and proven performance make it the preferred choice for reinforcing concrete in a variety of construction projects.

Basalt Fiber Reinforcement: Composition and Properties

Basalt fiber reinforcement is composed of fine fibers derived from basalt rock, offering exceptional tensile strength and durability compared to traditional steel rebar. Its high corrosion resistance and lightweight nature enhance structural longevity and reduce transportation costs in construction projects. Superior thermal stability and chemical inertness make basalt fiber reinforcement ideal for harsh environments where steel rebar is prone to degradation.

Comparative Structural Performance

Steel rebar exhibits high tensile strength and ductility, making it ideal for handling dynamic loads and seismic forces in concrete structures. Basalt fiber reinforcement offers superior corrosion resistance and lightweight properties but generally has lower tensile strength compared to steel rebar. In critical load-bearing applications, steel rebar provides better structural performance, while basalt fiber is advantageous in environments prone to corrosion and chemical exposure.

Corrosion Resistance: Steel Rebar vs Basalt Fiber

Basalt fiber reinforcement offers superior corrosion resistance compared to traditional steel rebar, as it is inherently immune to rust and chemical degradation in harsh environments. Steel rebar requires protective coatings or treatments to mitigate corrosion risks, which can increase maintenance costs and reduce structural longevity. Utilizing basalt fiber reinforcement enhances durability in concrete structures exposed to moisture, chlorides, and acidic conditions, significantly extending service life.

Cost Analysis and Lifecycle Value

Steel rebar typically presents a higher initial cost due to raw material and manufacturing expenses, while basalt fiber reinforcement offers cost savings through lower material weight and reduced transportation costs. Over the lifecycle, basalt fiber's superior corrosion resistance translates to decreased maintenance and replacement expenses, enhancing long-term value compared to steel rebar's susceptibility to rust and deterioration. Evaluating total cost of ownership, basalt fiber reinforcement can provide better economic efficiency in infrastructure projects subjected to harsh environmental conditions.

Installation and Handling Differences

Steel rebar requires heavy equipment for cutting, bending, and tying due to its rigidity and weight, making installation labor-intensive and time-consuming. Basalt fiber reinforcement is lightweight, corrosion-resistant, and flexible, allowing for easier cutting, handling, and faster placement without specialized tools. These differences reduce overall labor costs and improve efficiency on construction sites when using basalt fiber compared to traditional steel rebar.

Environmental Impact and Sustainability

Steel rebar production emits significant CO2, contributing heavily to environmental degradation, whereas basalt fiber reinforcement offers a lower carbon footprint due to energy-efficient manufacturing processes. Basalt fibers are non-corrosive and have a longer lifespan, reducing maintenance and replacement needs, which enhances sustainability in construction projects. Utilizing basalt fiber reinforcement supports eco-friendly building practices by decreasing resource consumption and minimizing waste compared to traditional steel rebar.

Typical Applications in Construction Projects

Steel rebar is predominantly used in high-load-bearing structures such as bridges, highways, and commercial buildings due to its superior tensile strength and ductility. Basalt fiber reinforcement finds typical applications in lightweight concrete panels, pavements, and marine structures where corrosion resistance and thermal stability are critical. Both materials enhance structural integrity, with steel preferred for traditional heavy construction and basalt fiber ideal for sustainable, durable solutions in harsh environments.

Future Trends in Reinforcement Technologies

Advancements in reinforcement technologies highlight the increasing use of basalt fiber as a sustainable alternative to traditional steel rebar, offering superior corrosion resistance and lighter weight for improved structural longevity. Research trends emphasize the integration of hybrid systems combining steel rebar with basalt fibers to enhance tensile strength and durability in concrete infrastructure. Innovations in composite materials and automated manufacturing processes are expected to drive wider adoption of basalt fiber reinforcement in future construction projects.

Related Important Terms

Corrosion-Resistant Reinforcement (CRR)

Steel rebar remains the most common reinforcement material due to its high tensile strength and cost-effectiveness, but basalt fiber reinforcement offers superior corrosion resistance, making it ideal for structures exposed to aggressive environments. Corrosion-resistant reinforcement (CRR) such as basalt fibers extends the lifespan of concrete by preventing rust-induced damage and reducing maintenance costs in infrastructure projects.

Non-Metallic Rebar (NMR)

Non-metallic rebars (NMR), such as basalt fiber reinforcement, offer superior corrosion resistance and lighter weight compared to traditional steel rebar, enhancing durability and reducing maintenance costs in concrete structures. Basalt fiber rebar exhibits high tensile strength and excellent thermal stability, making it an ideal choice for infrastructure exposed to harsh environments and chemical exposure.

Basalt Fiber Reinforced Polymer (BFRP)

Basalt Fiber Reinforced Polymer (BFRP) offers superior corrosion resistance and higher tensile strength compared to traditional steel rebar, making it ideal for structures exposed to harsh environments such as bridges and marine facilities. BFRP's lightweight nature and non-conductive properties reduce maintenance costs and improve durability, enhancing the longevity and safety of concrete reinforcements.

Magnetic Permeability Differential

Steel rebar exhibits high magnetic permeability, making it susceptible to electromagnetic interference and affecting structural health monitoring systems, whereas basalt fiber reinforcement has negligible magnetic permeability, ensuring better compatibility with non-destructive testing technologies. This magnetic permeability differential influences the choice of reinforcement in applications requiring precise magnetic or electromagnetic evaluations for durability and safety assessments.

Alkali Resistance Index

Steel rebar typically exhibits lower alkali resistance compared to basalt fiber reinforcement, which maintains its structural integrity in highly alkaline cement environments due to its high Alkali Resistance Index (ARI) above 130%. This superior alkali resistance of basalt fiber minimizes corrosion risks and enhances durability in concrete construction.

Lightweight Structural Rebar

Lightweight structural rebar made from basalt fiber offers superior corrosion resistance and higher tensile strength compared to traditional steel rebar, significantly reducing structural weight and increasing durability in construction applications. Basalt fiber reinforcement also enhances thermal stability and reduces maintenance costs, making it an ideal choice for modern infrastructure projects aiming for longevity and sustainability.

High Thermal Stability Composite

Steel rebar offers excellent tensile strength but is susceptible to corrosion and thermal expansion under high temperatures, whereas basalt fiber reinforcement provides superior thermal stability, maintaining structural integrity in fire-prone environments. Basalt fibers exhibit resistance to thermal degradation up to 800degC, making them an ideal composite material for enhancing durability in high-temperature construction applications.

Galvanic Corrosion Mitigation

Galvanic corrosion mitigation is a critical advantage of basalt fiber reinforcement over steel rebar, as basalt fibers are non-metallic and electrically inert, preventing electrochemical reactions between different metals that accelerate corrosion. In contrast, steel rebar in concrete structures often suffers from galvanic corrosion due to exposure to moisture and chlorides, leading to compromised structural integrity and increased maintenance costs.

Rebar Modulus of Elasticity Gap

Steel rebar typically exhibits a modulus of elasticity around 200 GPa, significantly higher than basalt fiber reinforcement, which ranges between 85 and 90 GPa. This modulus gap impacts structural stiffness and load-bearing capacity, making steel rebar preferable for applications requiring high rigidity and deformation resistance.

Eco-Rebar Sustainability Scoring

Eco-Rebar Sustainability Scoring reveals that basalt fiber reinforcement outperforms steel rebar due to its lower carbon footprint, reduced energy consumption during production, and recyclability. Steel rebar's higher embodied energy and susceptibility to corrosion make basalt fiber a more sustainable choice in modern construction projects aiming for green certification.

Steel Rebar vs Basalt Fiber Reinforcement Infographic

industrydif.com

industrydif.com