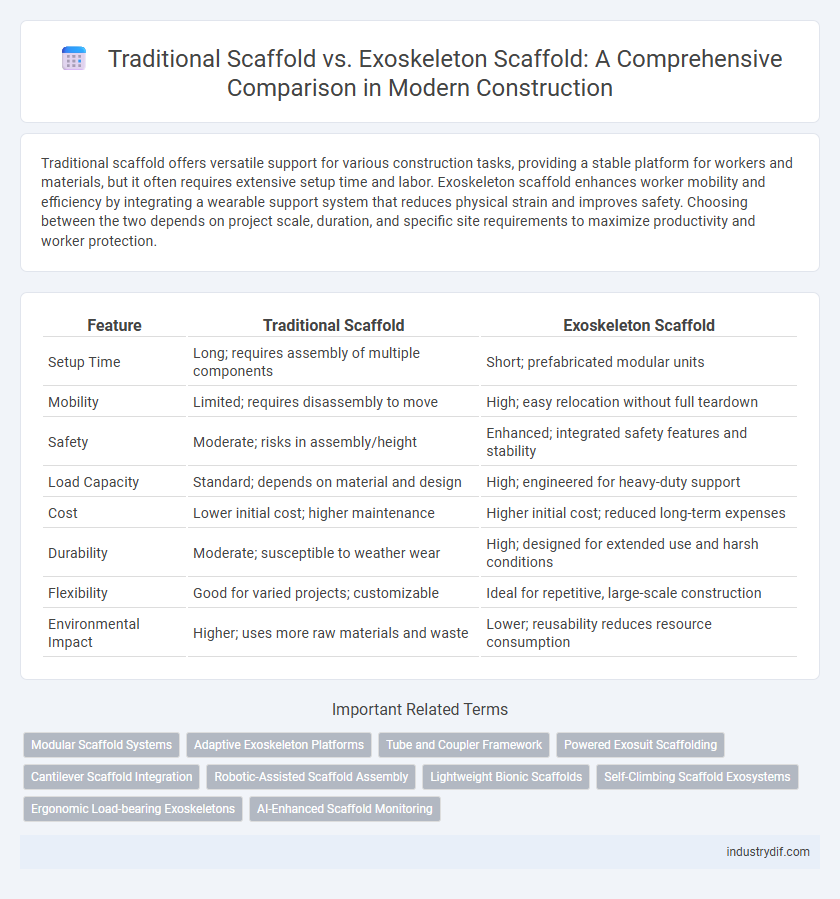

Traditional scaffold offers versatile support for various construction tasks, providing a stable platform for workers and materials, but it often requires extensive setup time and labor. Exoskeleton scaffold enhances worker mobility and efficiency by integrating a wearable support system that reduces physical strain and improves safety. Choosing between the two depends on project scale, duration, and specific site requirements to maximize productivity and worker protection.

Table of Comparison

| Feature | Traditional Scaffold | Exoskeleton Scaffold |

|---|---|---|

| Setup Time | Long; requires assembly of multiple components | Short; prefabricated modular units |

| Mobility | Limited; requires disassembly to move | High; easy relocation without full teardown |

| Safety | Moderate; risks in assembly/height | Enhanced; integrated safety features and stability |

| Load Capacity | Standard; depends on material and design | High; engineered for heavy-duty support |

| Cost | Lower initial cost; higher maintenance | Higher initial cost; reduced long-term expenses |

| Durability | Moderate; susceptible to weather wear | High; designed for extended use and harsh conditions |

| Flexibility | Good for varied projects; customizable | Ideal for repetitive, large-scale construction |

| Environmental Impact | Higher; uses more raw materials and waste | Lower; reusability reduces resource consumption |

Definition and Overview: Traditional Scaffold vs Exoskeleton Scaffold

Traditional scaffolds are temporary structures made of metal tubes and wooden planks assembled around buildings to provide support and access during construction or maintenance. Exoskeleton scaffolds consist of a permanent outer framework attached to the building, designed to enhance structural support and simplify future renovation work. The key difference lies in traditional scaffolds being removable and externally assembled, whereas exoskeleton scaffolds integrate with the building's exterior for long-term use.

Historical Evolution of Construction Scaffolding

Traditional scaffolding, characterized by timber and steel tube frameworks, has been a cornerstone of construction for centuries, evolving from rudimentary wooden structures used in ancient civilizations. The introduction of exoskeleton scaffolds marks a significant advancement, offering enhanced modularity, safety, and load-bearing capacity through prefabricated metal components. This evolution reflects ongoing technological innovations aimed at improving efficiency and worker protection in modern construction projects.

Core Materials and Structural Differences

Traditional scaffolds primarily use steel or aluminum tubes connected by couplers, providing a modular framework that relies on external bracing for stability. Exoskeleton scaffolds integrate a rigid frame made of high-strength steel or composite materials that envelop the structure, offering enhanced load-bearing capacity and resistance to lateral forces. These core material choices and structural designs result in exoskeleton scaffolds delivering greater durability, faster assembly, and improved safety compared to traditional scaffold systems.

Safety Considerations and Compliance Standards

Traditional scaffolds require regular inspection to meet OSHA safety standards, with risks including falls from unsecured platforms and scaffolding instability. Exoskeleton scaffolds enhance worker safety by providing built-in structural support and fall protection systems, aligning with ANSI/ASSE compliance for ergonomic hazard reduction. Both scaffold types must follow strict safety protocols, but exoskeleton scaffolds offer advanced features that reduce accident rates and improve compliance adherence on modern construction sites.

Installation Processes: Time and Labor Requirements

Traditional scaffold installation demands extensive labor and longer time frames due to its sequential assembly of multiple components, often requiring skilled workers for safety compliance. Exoskeleton scaffold systems significantly reduce installation time and labor by utilizing prefabricated modular units that streamline assembly and minimize on-site adjustments. This efficiency translates into cost savings and faster project timelines, enhancing overall construction productivity.

Cost Analysis: Initial Investment and Long-Term Value

Traditional scaffolds require a lower initial investment, typically ranging from $15 to $30 per square foot, but demand higher ongoing labor and maintenance costs due to assembly and disassembly complexity. Exoskeleton scaffolds involve higher upfront costs, often exceeding $50 per square foot, justified by reduced installation time, enhanced safety, and minimized downtime that drive long-term savings. Over a project lifecycle, exoskeleton scaffolds offer superior value through durability and efficiency, offsetting the initial premium compared to traditional scaffolding methods.

Flexibility and Adaptability on Job Sites

Traditional scaffolds offer limited flexibility due to fixed configurations and require extensive assembly to modify height or shape, slowing down project timelines. Exoskeleton scaffolds provide superior adaptability with modular components that can be quickly reconfigured to accommodate complex building geometries and variable job site conditions. This enhanced flexibility reduces labor costs and downtime, making exoskeleton scaffolding more efficient for dynamic construction environments.

Impact on Worker Productivity and Ergonomics

Traditional scaffolds often limit worker mobility and access, leading to increased setup times and physical strain, which can reduce overall productivity and heighten the risk of musculoskeletal injuries. Exoskeleton scaffolds enhance ergonomics by providing adjustable support and improved load distribution, enabling workers to maintain better posture and move more freely, thereby boosting efficiency and reducing fatigue. Studies indicate that construction sites using exoskeleton scaffolds report up to a 25% increase in task completion speed and a significant decline in work-related musculoskeletal disorders compared to traditional scaffolding methods.

Maintenance, Durability, and Lifecycle

Traditional scaffolds require frequent maintenance due to their exposed components, which are susceptible to weather damage and wear, resulting in a shorter lifecycle averaging 5-7 years. In contrast, exoskeleton scaffolds feature robust materials like high-grade steel and advanced protective coatings that significantly enhance durability and reduce maintenance needs, extending their lifecycle up to 15-20 years. The improved structural integrity of exoskeleton scaffolds lowers lifecycle costs and downtime, making them a more efficient investment for long-term construction projects.

Future Trends in Scaffold Technology

Exoskeleton scaffolds represent a significant advancement over traditional scaffolding by integrating wearable technology that enhances worker mobility and safety on construction sites. Future trends in scaffold technology emphasize smart materials, lightweight composites, and IoT-enabled monitoring systems to improve structural integrity and real-time hazard detection. Adoption of exoskeleton scaffolds is expected to reduce labor fatigue and increase efficiency, revolutionizing high-rise construction and complex architectural projects.

Related Important Terms

Modular Scaffold Systems

Traditional scaffold systems rely on fixed, sequential assembly methods that can limit flexibility and increase labor time, while exoskeleton scaffold systems feature modular components designed for rapid installation and enhanced structural adaptability. Modular scaffold systems in exoskeleton designs offer superior load distribution, improved safety standards, and scalability for complex construction projects, optimizing both efficiency and worker mobility.

Adaptive Exoskeleton Platforms

Adaptive exoskeleton platforms in construction scaffold technology enhance worker safety and efficiency by dynamically adjusting support based on real-time movement and load. Unlike traditional scaffolds, these advanced exoskeletons reduce physical strain, improve ergonomics, and enable precise positioning, significantly boosting productivity on complex building sites.

Tube and Coupler Framework

Traditional scaffold systems primarily rely on tube and coupler frameworks constructed from steel or aluminum tubes connected by clamps, offering flexibility and ease of assembly on various construction sites. Exoskeleton scaffolds integrate pre-engineered tube and coupler components with modular design principles to enhance structural stability, reduce setup time, and improve safety by providing external support to building facades.

Powered Exosuit Scaffolding

Powered exosuit scaffolding integrates wearable robotic technology to enhance worker mobility and safety, significantly reducing physical strain compared to traditional scaffolding systems. This innovation increases efficiency on construction sites by enabling workers to perform tasks at height with greater stability and reduced risk of injury.

Cantilever Scaffold Integration

Cantilever scaffold integration in construction enhances load-bearing capacity by supporting platforms on projecting beams, eliminating ground support needs typical in traditional scaffolds. Exoskeleton scaffold designs provide superior stability and flexibility for cantilever applications, enabling efficient access to complex structures while reducing material usage compared to conventional scaffolding systems.

Robotic-Assisted Scaffold Assembly

Robotic-assisted scaffold assembly significantly enhances efficiency and safety compared to traditional scaffold methods by automating repetitive tasks and reducing manual labor risks. Exoskeleton scaffolds integrated with robotic systems enable faster erection and dismantling processes while improving worker ergonomics and precision on construction sites.

Lightweight Bionic Scaffolds

Lightweight bionic scaffolds in construction leverage advanced materials and biomimetic designs to surpass traditional and exoskeleton scaffolds by offering enhanced strength-to-weight ratios and improved flexibility. These innovative frameworks reduce labor costs and assembly time while maximizing safety and adaptability on complex building sites.

Self-Climbing Scaffold Exosystems

Self-climbing scaffold exosystems offer enhanced safety and efficiency by automatically adjusting height without external support, unlike traditional scaffolds that require manual assembly and dismantling. These exoskeleton scaffolds minimize labor costs and downtime on high-rise construction projects, optimizing workflow and structural stability.

Ergonomic Load-bearing Exoskeletons

Ergonomic load-bearing exoskeletons in construction offer significant advantages over traditional scaffolds by reducing physical strain and improving worker posture during heavy lifting and extended tasks. These advanced wearable systems enhance mobility and safety while distributing weight efficiently, leading to increased productivity and decreased risk of musculoskeletal injuries on site.

AI-Enhanced Scaffold Monitoring

AI-enhanced scaffold monitoring leverages real-time data analytics and sensor integration to optimize safety and efficiency, with exoskeleton scaffolds providing superior structural adaptability and load-bearing capabilities compared to traditional scaffolds. This advanced monitoring system facilitates predictive maintenance and immediate hazard detection, significantly reducing construction site risks and downtime.

Traditional Scaffold vs Exoskeleton Scaffold Infographic

industrydif.com

industrydif.com