Preventive maintenance involves scheduled inspections and routine upkeep to reduce equipment failures, relying on historical data and fixed intervals. Predictive maintenance uses real-time data and advanced analytics to anticipate issues before they occur, optimizing repair schedules and minimizing downtime. Both strategies aim to enhance asset longevity and operational efficiency but differ in approach and technological dependency.

Table of Comparison

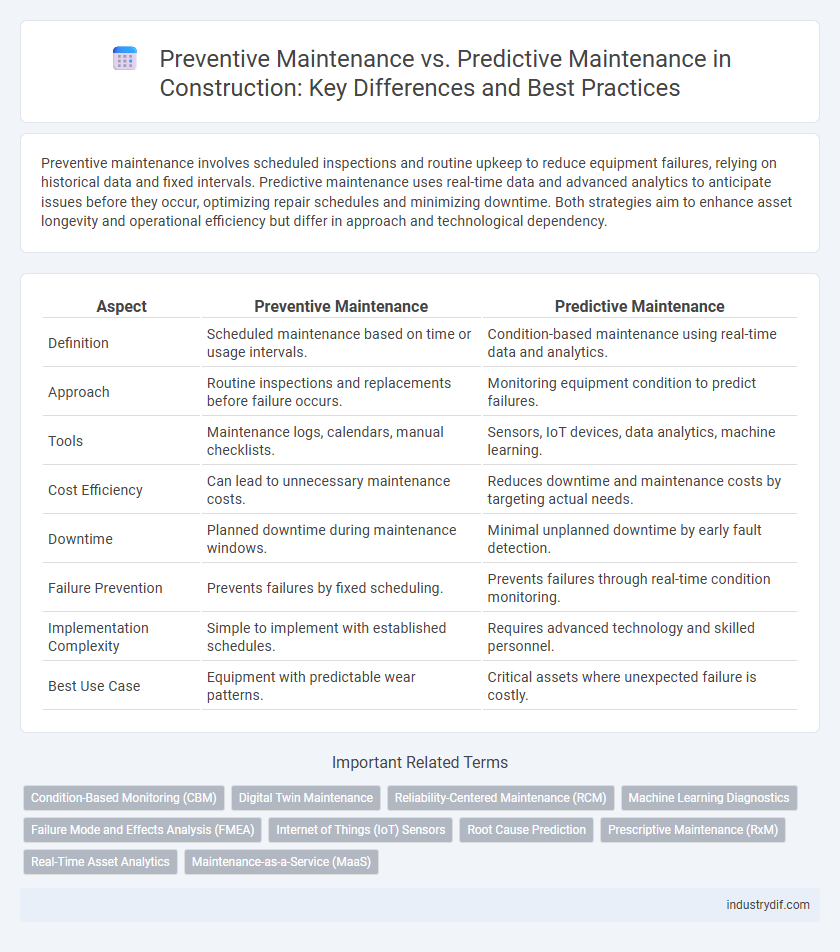

| Aspect | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Definition | Scheduled maintenance based on time or usage intervals. | Condition-based maintenance using real-time data and analytics. |

| Approach | Routine inspections and replacements before failure occurs. | Monitoring equipment condition to predict failures. |

| Tools | Maintenance logs, calendars, manual checklists. | Sensors, IoT devices, data analytics, machine learning. |

| Cost Efficiency | Can lead to unnecessary maintenance costs. | Reduces downtime and maintenance costs by targeting actual needs. |

| Downtime | Planned downtime during maintenance windows. | Minimal unplanned downtime by early fault detection. |

| Failure Prevention | Prevents failures by fixed scheduling. | Prevents failures through real-time condition monitoring. |

| Implementation Complexity | Simple to implement with established schedules. | Requires advanced technology and skilled personnel. |

| Best Use Case | Equipment with predictable wear patterns. | Critical assets where unexpected failure is costly. |

Introduction to Maintenance Strategies in Construction

Preventive maintenance in construction involves scheduled inspections and routine servicing of equipment to reduce the risk of unexpected failures, extending machinery lifespan and ensuring safety on site. Predictive maintenance uses data analytics, sensor technology, and real-time monitoring to anticipate equipment issues before they occur, optimizing resource allocation and minimizing downtime. Both strategies are crucial for maintaining operational efficiency, with preventive maintenance offering routine care and predictive maintenance enabling proactive decision-making based on equipment condition.

Definition of Preventive Maintenance

Preventive maintenance in construction involves scheduled inspections and upkeep activities designed to reduce equipment wear and prevent unexpected failures. It relies on time-based intervals or usage metrics, such as hours of operation or mileage, to perform routine tasks like lubrication, adjustments, and parts replacement. This proactive approach ensures machinery reliability, extends asset life, and minimizes costly downtime on construction sites.

Definition of Predictive Maintenance

Predictive maintenance in construction utilizes real-time data and advanced analytics to forecast equipment failures before they occur, minimizing unplanned downtime and optimizing machinery lifespan. This approach relies on sensors, IoT technology, and machine learning to detect abnormalities and predict when maintenance should be performed, enhancing operational efficiency. By proactively addressing potential issues, predictive maintenance reduces repair costs and improves safety on construction sites.

Key Differences Between Preventive and Predictive Maintenance

Preventive maintenance in construction involves scheduled inspections and routine servicing to reduce equipment failure risks, relying on time-based intervals. Predictive maintenance uses real-time data and advanced analytics, such as vibration analysis and thermal imaging, to forecast equipment issues before they occur. Key differences include the reliance on fixed schedules for preventive maintenance versus condition-based triggers for predictive maintenance, leading to enhanced efficiency and reduced downtime with predictive strategies.

Benefits of Preventive Maintenance in Construction

Preventive maintenance in construction enhances equipment reliability by scheduling regular inspections and servicing, reducing unexpected breakdowns and costly downtime. It extends the lifespan of machinery, ensuring consistent performance and safety compliance on job sites. This proactive approach helps control maintenance costs by addressing potential issues before they escalate into major repairs.

Benefits of Predictive Maintenance in Construction

Predictive maintenance in construction significantly reduces equipment downtime by accurately forecasting failures through real-time data and sensor analysis. This approach extends machinery lifespan and optimizes resource allocation, leading to substantial cost savings and enhanced project timelines. Enhanced safety is achieved by addressing potential equipment issues before catastrophic breakdowns occur, minimizing risks on construction sites.

Challenges in Implementing Preventive Maintenance

Implementing preventive maintenance in construction faces challenges such as scheduling disruptions, inaccurate equipment usage data, and increased labor costs due to routine inspections. Incomplete records and lack of staff training can lead to overlooked maintenance tasks, resulting in unexpected equipment failures. Limited integration with digital tools also hinders effective tracking and optimization of maintenance schedules on construction sites.

Challenges in Implementing Predictive Maintenance

Challenges in implementing predictive maintenance in construction include high initial investment costs for advanced sensor technologies and data analytics platforms. Integrating predictive systems with existing equipment requires skilled personnel and can lead to operational disruptions during the transition phase. Data accuracy and real-time processing limitations also hinder the effectiveness of predictive maintenance strategies on construction sites.

Cost Implications: Preventive vs Predictive Maintenance

Preventive maintenance involves scheduled inspections and routine repairs, often leading to higher labor costs and potential unnecessary part replacements, increasing overall expenditures. Predictive maintenance leverages real-time data and condition monitoring technologies to identify faults before failure, optimizing resource allocation and significantly reducing unexpected downtime and repair costs. Investing in predictive maintenance systems can yield long-term cost savings by minimizing equipment wear, extending asset lifespan, and lowering operational disruptions on construction sites.

Selecting the Right Maintenance Approach for Construction Projects

Selecting the right maintenance approach for construction projects hinges on balancing cost-efficiency and equipment reliability. Preventive maintenance follows a scheduled timeline based on usage or time, effectively reducing unexpected breakdowns but sometimes leading to unnecessary services. Predictive maintenance leverages real-time data and condition monitoring to perform maintenance only when indicators show declining performance, optimizing resource allocation and extending machinery lifespan.

Related Important Terms

Condition-Based Monitoring (CBM)

Preventive maintenance relies on scheduled inspections and routine servicing to reduce equipment failure risks, while predictive maintenance uses advanced Condition-Based Monitoring (CBM) techniques such as vibration analysis, infrared thermography, and ultrasonic testing to assess real-time asset health and predict failures before they occur. Implementing CBM in construction machinery enables targeted interventions, optimizing machine uptime, reducing operational costs, and extending equipment lifespan through data-driven maintenance decisions.

Digital Twin Maintenance

Digital twin maintenance leverages real-time data and simulations to enhance predictive maintenance by forecasting equipment failures before they occur, reducing downtime and extending asset life. Preventive maintenance, based on scheduled inspections and part replacements, lacks the dynamic adaptability provided by digital twins, making predictive approaches more cost-effective and precise in construction asset management.

Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) in construction prioritizes Preventive Maintenance by scheduling routine inspections and upkeep to avoid equipment failure, enhancing operational reliability and safety. Predictive Maintenance under RCM leverages real-time data and condition monitoring technologies to forecast failures, enabling targeted interventions that reduce downtime and maintenance costs.

Machine Learning Diagnostics

Machine learning diagnostics in predictive maintenance leverage real-time data and advanced algorithms to detect early warning signs of equipment failure, optimizing uptime and reducing costly downtime in construction machinery. Preventive maintenance follows fixed schedules based on manufacturer recommendations, often leading to unnecessary service or overlooked emerging issues that machine learning can more accurately identify and address.

Failure Mode and Effects Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) plays a critical role in distinguishing preventive maintenance, which schedules regular inspections regardless of equipment condition, from predictive maintenance that relies on real-time data to forecast failures. By utilizing FMEA to identify potential failure modes and their impacts, construction firms optimize maintenance strategies, reduce downtime, and enhance equipment reliability through targeted interventions.

Internet of Things (IoT) Sensors

IoT sensors enable real-time data collection on equipment conditions, making predictive maintenance more efficient by forecasting failures before they occur, unlike preventive maintenance, which relies on scheduled inspections regardless of actual equipment status. Integrating IoT in construction sites reduces downtime and maintenance costs by allowing precise intervention only when sensor data indicates potential issues.

Root Cause Prediction

Preventive maintenance involves scheduled inspections and repairs to avoid equipment failure, whereas predictive maintenance leverages real-time data and advanced analytics to predict root causes of potential issues before they occur. Utilizing IoT sensors and machine learning algorithms in predictive maintenance enhances accuracy in root cause prediction, minimizing downtime and reducing unexpected costs in construction project management.

Prescriptive Maintenance (RxM)

Prescriptive Maintenance (RxM) in construction goes beyond preventive and predictive approaches by utilizing advanced data analytics, machine learning, and real-time sensor inputs to recommend specific actions that optimize equipment performance and reduce downtime. This proactive strategy enhances asset management by not only predicting failures but also prescribing maintenance tasks that maximize operational efficiency and extend machinery lifespan.

Real-Time Asset Analytics

Preventive maintenance schedules regular inspections and repairs to reduce equipment failure, while predictive maintenance leverages real-time asset analytics and IoT sensor data to forecast issues before they occur, optimizing uptime and reducing costs. Real-time asset analytics enable construction firms to monitor equipment health continuously, analyze performance trends, and trigger timely interventions, enhancing operational efficiency and extending asset lifespan.

Maintenance-as-a-Service (MaaS)

Maintenance-as-a-Service (MaaS) integrates both preventive maintenance, which schedules regular inspections to avoid equipment failure, and predictive maintenance, leveraging IoT sensors and AI analytics to forecast issues before they occur. This hybrid approach in construction enhances asset longevity, reduces downtime, and optimizes resource allocation by combining time-based routines with real-time condition monitoring.

Preventive Maintenance vs Predictive Maintenance Infographic

industrydif.com

industrydif.com