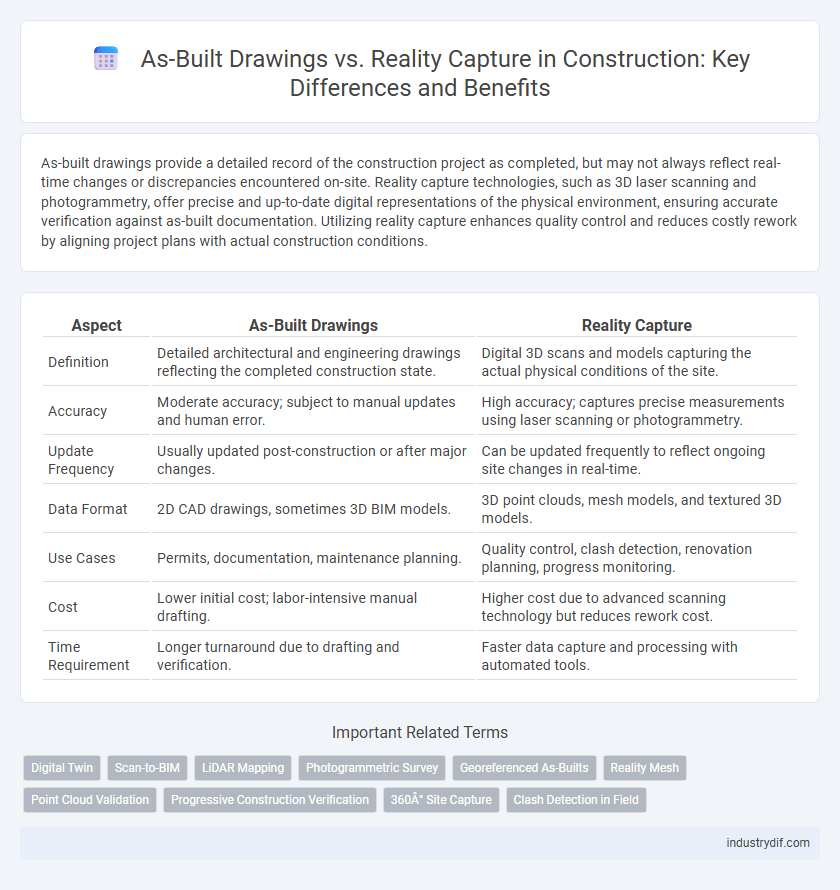

As-built drawings provide a detailed record of the construction project as completed, but may not always reflect real-time changes or discrepancies encountered on-site. Reality capture technologies, such as 3D laser scanning and photogrammetry, offer precise and up-to-date digital representations of the physical environment, ensuring accurate verification against as-built documentation. Utilizing reality capture enhances quality control and reduces costly rework by aligning project plans with actual construction conditions.

Table of Comparison

| Aspect | As-Built Drawings | Reality Capture |

|---|---|---|

| Definition | Detailed architectural and engineering drawings reflecting the completed construction state. | Digital 3D scans and models capturing the actual physical conditions of the site. |

| Accuracy | Moderate accuracy; subject to manual updates and human error. | High accuracy; captures precise measurements using laser scanning or photogrammetry. |

| Update Frequency | Usually updated post-construction or after major changes. | Can be updated frequently to reflect ongoing site changes in real-time. |

| Data Format | 2D CAD drawings, sometimes 3D BIM models. | 3D point clouds, mesh models, and textured 3D models. |

| Use Cases | Permits, documentation, maintenance planning. | Quality control, clash detection, renovation planning, progress monitoring. |

| Cost | Lower initial cost; labor-intensive manual drafting. | Higher cost due to advanced scanning technology but reduces rework cost. |

| Time Requirement | Longer turnaround due to drafting and verification. | Faster data capture and processing with automated tools. |

Understanding As-Built Drawings in Construction

As-built drawings provide a detailed record of the final constructed structure, reflecting all modifications made during the construction process. Understanding as-built drawings is essential for verifying compliance with design specifications, facilitating future renovations, and resolving disputes related to construction discrepancies. Integrating reality capture technologies, such as laser scanning and photogrammetry, enhances accuracy by directly comparing as-built drawings to the physical conditions on site.

What Is Reality Capture Technology?

Reality capture technology in construction utilizes advanced tools such as 3D laser scanning, photogrammetry, and drones to create precise digital models of physical sites. These technologies collect accurate spatial data that reflects the current conditions of a project, enabling detailed verification against design plans. Unlike traditional as-built drawings, reality capture provides real-time, high-resolution visualizations that enhance project accuracy, reduce errors, and improve decision-making during construction and renovation phases.

Key Differences Between As-Built Drawings and Reality Capture

As-built drawings provide a detailed, manual representation of the completed construction based on design changes and field measurements, while reality capture uses advanced technologies like laser scanning and photogrammetry to create precise 3D digital models of the physical site. As-built drawings often depend on human interpretation and can include inaccuracies or delays, whereas reality capture delivers real-time, highly accurate spatial data that reflects conditions exactly as they exist. Key differences lie in the accuracy, data acquisition methods, and the ability to visualize current site conditions for project validation and future renovations.

Traditional As-Built Documentation Methods

Traditional As-Built drawings rely heavily on manual measurements and hand annotations, often leading to inaccuracies and outdated information in construction projects. These conventional methods are time-consuming and prone to human error, making it challenging to maintain precise records of changes during construction. Reality capture technologies, such as 3D laser scanning and photogrammetry, offer more accurate and efficient alternatives by digitally documenting as-built conditions with high precision.

The Rise of Digital Reality Capture Solutions

Digital reality capture solutions, such as 3D laser scanning and photogrammetry, revolutionize as-built drawings by providing highly accurate and detailed representations of construction sites. Unlike traditional as-built drawings, which rely on manual measurements and can be prone to errors, these technologies deliver precise spatial data that enhances project accuracy and accelerates the verification process. The rise of digital reality capture improves collaboration, reduces rework, and supports efficient facility management throughout the building lifecycle.

Benefits of Reality Capture Over Conventional As-Builts

Reality capture technology offers precise 3D models and accurate site documentation, reducing human errors common in conventional as-built drawings. It significantly enhances project efficiency by providing comprehensive, real-time data, enabling better decision-making and reducing rework costs. High-resolution laser scanning and photogrammetry improve verification processes and facilitate seamless collaboration among stakeholders.

Accuracy and Reliability: As-Builts vs. Reality Capture

As-built drawings provide a traditional method of documenting completed construction projects, often relying on manual measurements that may introduce errors and reduce accuracy. Reality capture technologies, such as 3D laser scanning and photogrammetry, deliver highly precise and reliable data by digitally recording the exact conditions on-site. The enhanced accuracy and reliability of reality capture minimize discrepancies between design and construction, improving quality control and project outcomes.

Applications of Reality Capture in Modern Construction

Reality capture technology, such as 3D laser scanning and photogrammetry, revolutionizes modern construction by providing highly accurate, real-time data for project monitoring, quality control, and progress tracking. Unlike traditional as-built drawings, reality capture enables the creation of precise digital models that reflect current site conditions, improving coordination among stakeholders and reducing costly rework. Applications include clash detection, site surveying, and facility management, enhancing overall construction efficiency and project outcomes.

Challenges in Integrating Reality Capture with As-Built Drawings

Integrating reality capture with as-built drawings faces challenges such as discrepancies in scale, alignment, and level of detail between the two data sources, often leading to inconsistencies in spatial accuracy. The complexity of processing large reality capture datasets, like point clouds from 3D laser scanning or photogrammetry, requires advanced software and skilled personnel to effectively update as-built drawings. Furthermore, differing update cycles and standards between traditional drawings and frequent reality capture can result in time lags and data incompatibility, complicating seamless project documentation and coordination.

Future Trends: Evolving As-Built Documentation Practices

Future trends in construction emphasize integrating reality capture technologies such as 3D laser scanning and drone photogrammetry to enhance the accuracy of as-built drawings. These advancements enable real-time updates and digital twin creation, improving project management and facility maintenance. The shift towards automated data processing and cloud-based collaboration platforms is transforming as-built documentation into a dynamic, continuously updated resource.

Related Important Terms

Digital Twin

As-Built Drawings provide a static, accurate representation of a completed construction project, while Reality Capture employs advanced technologies such as 3D laser scanning and photogrammetry to create dynamic, real-time digital models. Digital Twin technology integrates Reality Capture data to offer an interactive, up-to-date virtual replica of physical assets, enabling enhanced project monitoring, facility management, and predictive maintenance.

Scan-to-BIM

Scan-to-BIM leverages reality capture technologies such as 3D laser scanning to generate highly accurate as-built drawings that reflect actual site conditions, reducing discrepancies between design intent and construction outcomes. This integration enhances project coordination, minimizes rework, and provides a comprehensive digital twin that supports facility management and future renovations.

LiDAR Mapping

As-built drawings provide a static representation of construction projects, but LiDAR mapping offers precise, real-time 3D spatial data that captures the exact conditions on-site, improving accuracy and reducing discrepancies. Integrating LiDAR-based reality capture with traditional as-built documentation enhances project verification, clash detection, and progress monitoring in construction workflows.

Photogrammetric Survey

Photogrammetric surveys provide highly accurate 3D models that enhance As-Built Drawings by capturing real-world conditions with precision, reducing discrepancies between design plans and actual site status. Implementing photogrammetry in construction projects enables efficient verification and updates of As-Built Drawings, improving project documentation and quality control.

Georeferenced As-Builts

Georeferenced As-Built drawings integrate precise spatial data from reality capture technologies such as laser scanning and photogrammetry, enabling exact alignment of construction elements with geographic coordinates. This fusion improves accuracy in project documentation and facilitates easier updates and clash detection during construction and post-construction phases.

Reality Mesh

Reality mesh technology revolutionizes construction by generating precise 3D models from reality capture data, enhancing accuracy beyond traditional as-built drawings. Integrating reality meshes enables real-time project updates, minimizes discrepancies, and streamlines quality control throughout the construction lifecycle.

Point Cloud Validation

Point cloud validation in construction ensures as-built drawings accurately reflect site conditions by comparing laser-scanned 3D data with design models. This process detects deviations, enhances quality control, and supports precise project documentation and compliance.

Progressive Construction Verification

Progressive construction verification leverages as-built drawings and reality capture technologies to ensure ongoing accuracy between planned designs and actual site conditions. High-definition 3D laser scanning and photogrammetry enable precise comparisons against as-built models, minimizing discrepancies and improving project quality control throughout construction phases.

360° Site Capture

360deg site capture offers a comprehensive visual record that enhances the accuracy of as-built drawings by providing detailed, real-time spatial data. Integrating 360deg imagery with reality capture technology reduces discrepancies between design plans and actual site conditions, streamlining project documentation and verification processes.

Clash Detection in Field

As-built drawings provide a static representation of completed construction elements, often leading to discrepancies during clash detection in the field due to outdated or incomplete information. Reality capture technologies, such as 3D laser scanning and photogrammetry, enable precise and real-time detection of clashes by creating accurate digital twins, improving issue identification and resolution on-site.

As-Built Drawings vs Reality Capture Infographic

industrydif.com

industrydif.com