Steel rebar offers high tensile strength and durability, making it a traditional choice for concrete reinforcement, while carbon fiber reinforcement provides superior corrosion resistance and lighter weight with comparable strength. The use of carbon fiber reduces structural weight and enhances longevity, especially in environments prone to moisture and chemical exposure. Cost considerations and project requirements often dictate the optimal selection between steel and carbon fiber reinforcement materials.

Table of Comparison

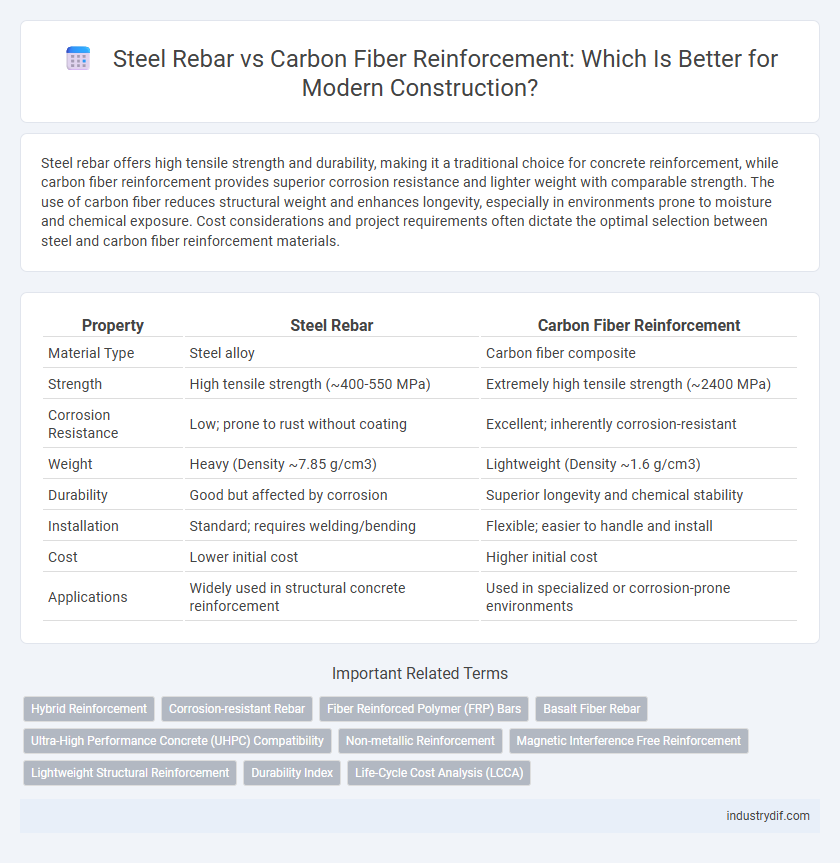

| Property | Steel Rebar | Carbon Fiber Reinforcement |

|---|---|---|

| Material Type | Steel alloy | Carbon fiber composite |

| Strength | High tensile strength (~400-550 MPa) | Extremely high tensile strength (~2400 MPa) |

| Corrosion Resistance | Low; prone to rust without coating | Excellent; inherently corrosion-resistant |

| Weight | Heavy (Density ~7.85 g/cm3) | Lightweight (Density ~1.6 g/cm3) |

| Durability | Good but affected by corrosion | Superior longevity and chemical stability |

| Installation | Standard; requires welding/bending | Flexible; easier to handle and install |

| Cost | Lower initial cost | Higher initial cost |

| Applications | Widely used in structural concrete reinforcement | Used in specialized or corrosion-prone environments |

Introduction to Reinforcement Materials in Construction

Steel rebar and carbon fiber reinforcement are critical materials for enhancing structural integrity in construction projects. Steel rebar offers high tensile strength and ductility, making it a traditional choice for load-bearing concrete structures. Carbon fiber reinforcement provides superior corrosion resistance and lightweight properties, gaining popularity in modern applications requiring durability and reduced maintenance.

Understanding Steel Rebar: Properties and Applications

Steel rebar exhibits high tensile strength, ductility, and corrosion resistance, making it a reliable reinforcement material in concrete structures. Its ability to bond well with concrete and endure significant stress enhances structural integrity in foundations, beams, and columns. Common applications include residential, commercial, and infrastructure projects where load-bearing capacity and durability are critical.

Overview of Carbon Fiber Reinforcement Technology

Carbon fiber reinforcement technology offers superior strength-to-weight ratios compared to traditional steel rebar, making it a preferred choice for reducing structural weight without compromising durability. This advanced material exhibits excellent corrosion resistance, significantly extending the lifespan of reinforced concrete structures in harsh environments. Its non-magnetic and non-conductive properties also enhance safety and performance in specialized construction applications.

Comparative Strength and Performance Analysis

Steel rebar offers high tensile strength and excellent ductility, making it a preferred choice for traditional concrete reinforcement with proven durability under dynamic loads. Carbon fiber reinforcement provides superior strength-to-weight ratio, corrosion resistance, and enhanced fatigue performance, which extends structural lifespan in harsh environments. Performance analysis indicates carbon fiber's reduced weight and non-corrosive properties lead to lower maintenance costs, while steel rebar remains cost-effective with well-established construction standards.

Durability and Corrosion Resistance

Steel rebar offers high tensile strength but is prone to corrosion, reducing its durability in harsh environments. Carbon fiber reinforcement provides exceptional corrosion resistance and maintains structural integrity over time, making it ideal for aggressive or marine conditions. Choosing carbon fiber can significantly extend the lifespan of reinforced concrete structures by preventing rust-related deterioration.

Installation Techniques and Construction Practices

Steel rebar installation requires precise bending, tying, and placement within formwork to ensure structural integrity, while carbon fiber reinforcement involves layering and bonding with epoxy or resin to existing surfaces. The steel rebar method demands heavy lifting and welding equipment, whereas carbon fiber techniques emphasize surface preparation and curing time for optimal adhesion. Construction practices using carbon fiber reinforcement reduce labor intensity and corrosion concerns, offering faster application and enhanced durability in challenging environments.

Cost Considerations: Steel Rebar vs Carbon Fiber

Steel rebar remains the more cost-effective option for large-scale construction projects due to lower material and installation expenses, typically ranging from $0.75 to $1.50 per pound. Carbon fiber reinforcement, while offering superior corrosion resistance and tensile strength, commands higher upfront costs, averaging $10 to $20 per pound. Long-term durability and reduced maintenance can offset these initial expenses, making carbon fiber economically viable for specialized applications with strict performance requirements.

Sustainability and Environmental Impact

Steel rebar, traditionally used for concrete reinforcement, has a high environmental footprint due to its energy-intensive production and carbon emissions, while carbon fiber reinforcement offers a lightweight, corrosion-resistant alternative with significantly lower lifecycle emissions. Carbon fiber's durability extends the lifespan of structures, reducing the need for frequent repairs and material replacement, thus minimizing waste over time. Sustainability in construction increasingly favors carbon fiber reinforcement for its potential to reduce resource consumption and enhance resilience in infrastructure projects.

Industry Standards and Compliance

Steel rebar remains the standard reinforcement material in construction due to its compliance with ASTM A615 and A706 industry standards, ensuring consistent tensile strength and ductility. Carbon fiber reinforcement, governed by guidelines such as ACI 440.8R-18, offers superior corrosion resistance and lightweight properties but requires specialized testing protocols for structural compliance. Both materials must meet rigorous building codes like the International Building Code (IBC) to ensure safety and durability in reinforced concrete applications.

Future Trends in Reinforcement Materials

Future trends in reinforcement materials emphasize the increasing use of carbon fiber reinforcement due to its superior strength-to-weight ratio, corrosion resistance, and ease of installation compared to traditional steel rebar. Innovations in composite technologies and nanomaterials are accelerating the adoption of carbon fiber in infrastructure projects, promising enhanced durability and reduced maintenance costs. Ongoing research focuses on hybrid reinforcement systems that combine steel rebar and carbon fiber to optimize performance in diverse construction environments.

Related Important Terms

Hybrid Reinforcement

Hybrid reinforcement combining steel rebar and carbon fiber offers enhanced structural performance by leveraging steel's high tensile strength and carbon fiber's corrosion resistance and lightweight properties. This integration improves durability, reduces maintenance costs, and optimizes load-bearing capacity in advanced construction projects.

Corrosion-resistant Rebar

Corrosion-resistant rebar, such as epoxy-coated steel and stainless steel variants, significantly extends the lifespan of concrete structures by preventing rust and deterioration compared to traditional carbon fiber reinforcement, which, while lightweight and strong, can be more costly and less effective in basal corrosion protection. Optimizing the use of corrosion-resistant steel rebar in marine, bridge, and industrial environments enhances structural integrity and reduces long-term maintenance costs.

Fiber Reinforced Polymer (FRP) Bars

Fiber Reinforced Polymer (FRP) bars offer superior corrosion resistance and lightweight properties compared to traditional steel rebar, making them ideal for structures exposed to harsh environments or requiring reduced structural weight. The high tensile strength and non-conductive nature of FRP bars enhance durability and longevity in construction applications such as bridges, marine structures, and parking decks.

Basalt Fiber Rebar

Basalt fiber rebar offers superior corrosion resistance and high tensile strength compared to traditional steel rebar, making it ideal for extending the lifespan of concrete structures in aggressive environments. This composite material combines the benefits of carbon fiber reinforcement, such as lightweight and durability, with enhanced cost-effectiveness and eco-friendly properties.

Ultra-High Performance Concrete (UHPC) Compatibility

Steel rebar provides traditional tensile strength but is prone to corrosion when embedded in Ultra-High Performance Concrete (UHPC), potentially compromising durability. Carbon fiber reinforcement offers superior corrosion resistance and tensile strength, enhancing UHPC's mechanical performance and extending structural lifespan in aggressive environments.

Non-metallic Reinforcement

Carbon fiber reinforcement offers superior corrosion resistance and higher tensile strength compared to traditional steel rebar, making it ideal for structures exposed to harsh environmental conditions. Non-metallic reinforcement like carbon fiber reduces maintenance costs and extends the lifespan of concrete elements without compromising structural integrity.

Magnetic Interference Free Reinforcement

Carbon fiber reinforcement offers a magnetic interference-free alternative to traditional steel rebar, making it ideal for applications requiring non-conductive materials in environments with sensitive electronic equipment or MRI facilities. Its corrosion-resistant properties and lightweight nature also enhance structural longevity and ease of installation, outperforming steel rebar in durability and electromagnetic compatibility.

Lightweight Structural Reinforcement

Steel rebar, traditionally used for structural reinforcement, offers high tensile strength but adds significant weight to construction projects, increasing overall load and transportation costs. Carbon fiber reinforcement provides a lightweight alternative with superior strength-to-weight ratio and corrosion resistance, making it ideal for applications requiring reduced structural weight and enhanced durability.

Durability Index

Steel rebar exhibits a Durability Index of approximately 60-70 due to its susceptibility to corrosion and fatigue under harsh environmental conditions. Carbon fiber reinforcement surpasses steel with a Durability Index above 90, offering superior resistance to corrosion, tensile strength, and longevity in concrete structures.

Life-Cycle Cost Analysis (LCCA)

Steel rebar typically presents higher initial costs but demonstrates proven durability and ease of installation, while carbon fiber reinforcement offers superior corrosion resistance and longer lifespan, reducing long-term maintenance and replacement expenses. Life-Cycle Cost Analysis (LCCA) reveals carbon fiber reinforcement can achieve lower total costs over a 50-year period due to minimal degradation and reduced structural repairs compared to traditional steel rebar.

Steel Rebar vs Carbon Fiber Reinforcement Infographic

industrydif.com

industrydif.com