Concrete mix typically consists of cement, water, sand, and aggregates, offering adequate strength and durability for general construction projects. Ultra-High Performance Concrete (UHPC) incorporates advanced materials and a refined particle matrix, resulting in significantly enhanced compressive strength, durability, and resistance to environmental degradation. This superior performance makes UHPC ideal for structures demanding exceptional longevity and load-bearing capacity, such as bridges and high-rise buildings.

Table of Comparison

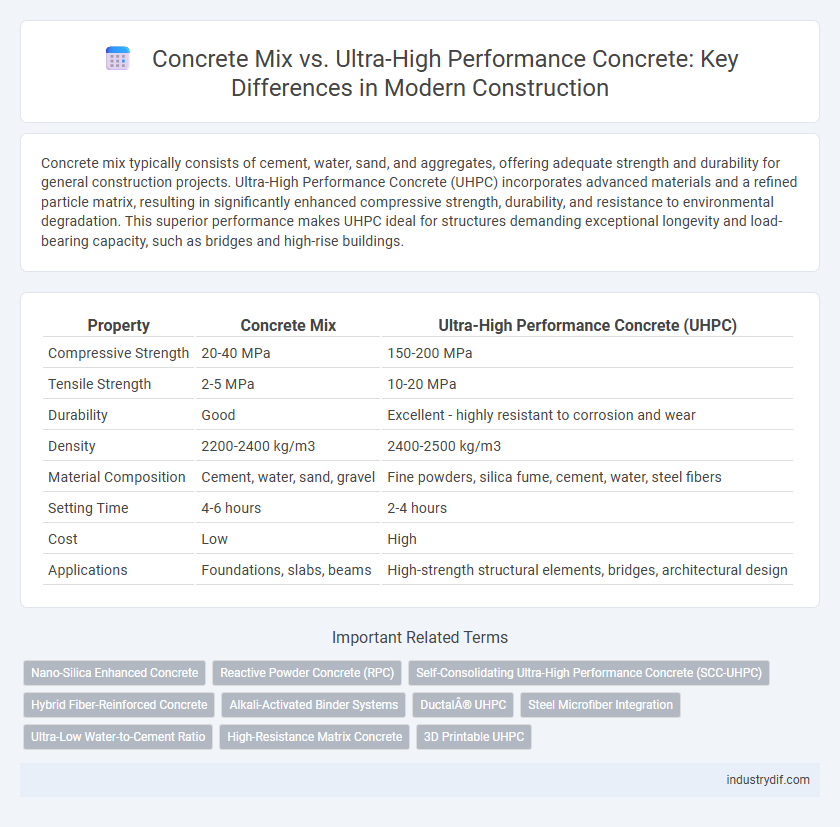

| Property | Concrete Mix | Ultra-High Performance Concrete (UHPC) |

|---|---|---|

| Compressive Strength | 20-40 MPa | 150-200 MPa |

| Tensile Strength | 2-5 MPa | 10-20 MPa |

| Durability | Good | Excellent - highly resistant to corrosion and wear |

| Density | 2200-2400 kg/m3 | 2400-2500 kg/m3 |

| Material Composition | Cement, water, sand, gravel | Fine powders, silica fume, cement, water, steel fibers |

| Setting Time | 4-6 hours | 2-4 hours |

| Cost | Low | High |

| Applications | Foundations, slabs, beams | High-strength structural elements, bridges, architectural design |

Understanding Standard Concrete Mix

Standard concrete mix consists primarily of cement, water, fine aggregates like sand, and coarse aggregates such as gravel, designed to achieve compressive strengths typically ranging from 3,000 to 5,000 psi. It provides adequate durability and workability for most conventional construction tasks but lacks the exceptional strength, ductility, and durability features found in Ultra-High Performance Concrete (UHPC), which can exceed compressive strengths of 20,000 psi. Understanding the composition and limitations of standard concrete mix is crucial for selecting appropriate materials based on the structural demands and environmental exposure conditions of a project.

Introduction to Ultra-High Performance Concrete (UHPC)

Ultra-High Performance Concrete (UHPC) is an advanced construction material characterized by its superior strength, durability, and enhanced ductility compared to traditional concrete mixes. Composed of a refined blend of cement, silica fume, quartz sand, superplasticizers, and steel or organic fibers, UHPC achieves compressive strengths exceeding 150 MPa and exceptional resistance to environmental degradation. Its microstructure, optimized at the nanoscale, enables ultra-dense packing and reduced porosity, making UHPC ideal for infrastructure projects requiring long service life and minimal maintenance.

Key Material Differences

Concrete mix typically consists of cement, water, aggregates, and admixtures, providing standard compressive strength ranging from 20 to 40 MPa. Ultra-high performance concrete (UHPC) incorporates fine powders, silica fume, and steel fibers, achieving compressive strengths exceeding 150 MPa with enhanced durability and tensile strength. The dense microstructure and reduced porosity in UHPC result from optimized particle packing and low water-to-cement ratios compared to conventional concrete mixes.

Strength and Durability Comparison

Ultra-High Performance Concrete (UHPC) exhibits compressive strength exceeding 150 MPa, significantly outperforming traditional concrete mix strength ranges of 20-40 MPa. UHPC also offers superior durability, resisting sulfate attack, freeze-thaw cycles, and chloride ion penetration far better than conventional concrete, ensuring extended service life in harsh environments. High density and improved microstructure of UHPC contribute to its enhanced mechanical properties and longevity compared to standard concrete mixes.

Workability and Placement Techniques

Concrete mix offers moderate workability suitable for standard placement techniques such as pouring and vibrating in typical construction scenarios. Ultra-High Performance Concrete (UHPC) exhibits superior flowability and self-compacting properties, allowing for complex shapes and thin sections without extensive mechanical consolidation. Placement techniques for UHPC often include specialized pumping and precision casting methods to optimize its dense microstructure and high-strength characteristics.

Cost Implications and Budget Considerations

Concrete mix typically offers a cost-effective solution for standard construction projects, with prices ranging from $100 to $150 per cubic yard, making it suitable for budget-conscious builds. Ultra-high performance concrete (UHPC) can cost up to $2,500 per cubic yard due to its advanced composition and superior strength, significantly impacting overall project budgets. Evaluating the balance between initial material costs and long-term durability benefits is essential for optimized budget allocation in construction planning.

Applications in Modern Construction

Concrete mix is widely used for general construction projects such as foundations, slabs, and beams due to its cost-effectiveness and adequate strength for standard load-bearing structures. Ultra-high performance concrete (UHPC) offers superior durability, tensile strength, and resistance to environmental degradation, making it ideal for infrastructure requiring enhanced longevity like bridges, high-rise buildings, and seismic zones. Modern construction increasingly favors UHPC in applications demanding minimal maintenance and advanced performance, while conventional concrete mix remains prevalent for everyday structural elements.

Sustainability and Environmental Impact

Ultra-High Performance Concrete (UHPC) significantly reduces environmental impact by requiring less material volume due to its superior strength and durability compared to traditional concrete mixes. UHPC's enhanced longevity decreases the frequency of repairs and replacements, thereby minimizing resource consumption and carbon emissions over the structure's lifespan. In contrast, conventional concrete mixes often contribute to higher CO2 emissions and greater waste generation due to lower durability and increased maintenance needs.

Maintenance and Longevity

Ultra-High Performance Concrete (UHPC) offers superior durability and significantly reduced maintenance compared to traditional concrete mixes due to its dense microstructure and enhanced resistance to environmental stressors. The advanced composition of UHPC minimizes cracking, corrosion, and wear, ensuring longer service life in demanding construction applications. Conventional concrete requires more frequent repairs and maintenance to address common issues such as shrinkage, freeze-thaw damage, and reinforcing steel corrosion, leading to higher lifecycle costs.

Future Trends in Concrete Technology

Ultra-High Performance Concrete (UHPC) is revolutionizing construction by offering superior strength, durability, and reduced environmental impact compared to traditional concrete mixes. Advances in nanotechnology and fiber reinforcement are driving UHPC's enhanced mechanical properties and sustainability, enabling futuristic applications such as 3D-printed structures and resilient infrastructure. Ongoing research emphasizes optimizing mix designs to lower carbon footprints while maximizing performance, signaling a transformative shift in concrete technology for the construction industry.

Related Important Terms

Nano-Silica Enhanced Concrete

Nano-silica enhanced concrete significantly improves the durability and mechanical properties of both standard concrete mix and ultra-high performance concrete (UHPC) by refining the microstructure and reducing porosity. Incorporating nano-silica particles in UHPC leads to superior compressive strength exceeding 150 MPa and enhanced resistance to chemical attack compared to conventional concrete mixes.

Reactive Powder Concrete (RPC)

Reactive Powder Concrete (RPC), a type of Ultra-High Performance Concrete (UHPC), offers superior compressive strength up to 800 MPa and enhanced durability compared to traditional concrete mixes, making it ideal for high-stress structural applications. Its finely ground quartz and steel fibers improve microstructure density and toughness, significantly reducing permeability and increasing resistance to chemical attack.

Self-Consolidating Ultra-High Performance Concrete (SCC-UHPC)

Self-Consolidating Ultra-High Performance Concrete (SCC-UHPC) combines the superior strength and durability of Ultra-High Performance Concrete with exceptional flowability, eliminating the need for mechanical vibration during placement. This innovative material enhances constructability in complex forms and densely reinforced structures, providing enhanced tensile strength, reduced porosity, and improved longevity compared to traditional concrete mixes.

Hybrid Fiber-Reinforced Concrete

Hybrid fiber-reinforced concrete (HFRC) integrates steel and synthetic fibers to enhance tensile strength, ductility, and crack resistance compared to traditional concrete mixes, offering a significant performance boost in structural applications. When combined with ultra-high performance concrete (UHPC), HFRC enables exceptional durability and load-bearing capacity, making it ideal for infrastructure projects requiring superior mechanical properties and extended service life.

Alkali-Activated Binder Systems

Alkali-activated binder systems in Ultra-High Performance Concrete (UHPC) offer superior mechanical strength and durability compared to traditional Portland cement-based concrete mixes, enhancing resistance to chemical attack and reducing carbon emissions. These innovative binders optimize microstructure development, enabling UHPC to achieve higher compressive strengths above 150 MPa, while conventional concrete typically ranges between 20-40 MPa.

Ductal® UHPC

Ductal(r) UHPC offers superior compressive strength exceeding 150 MPa and exceptional durability compared to traditional concrete mixes, making it ideal for infrastructure requiring high resilience and minimal maintenance. Its dense microstructure and fiber reinforcement deliver enhanced ductility and fracture toughness, outperforming standard concrete's typical 30-40 MPa strength and limited tensile capacity.

Steel Microfiber Integration

Concrete mix incorporates steel microfibers to enhance tensile strength and crack resistance, improving structural durability in standard construction applications. Ultra-high performance concrete (UHPC) uses a higher volume and optimized distribution of steel microfibers, resulting in superior mechanical properties, including exceptional toughness and fatigue resistance for advanced infrastructure projects.

Ultra-Low Water-to-Cement Ratio

Ultra-High Performance Concrete (UHPC) features an ultra-low water-to-cement ratio, typically below 0.20, significantly enhancing its density, strength, and durability compared to traditional concrete mixes that usually have ratios around 0.40 to 0.60. This reduced water content results in superior mechanical properties and resistance to environmental degradation, making UHPC ideal for demanding construction applications requiring high performance and longevity.

High-Resistance Matrix Concrete

Ultra-High Performance Concrete (UHPC) features a high-resistance matrix concrete composed of optimized blend proportions, including fine powders, silica fume, and low water-to-cement ratios that significantly enhance compressive strength beyond 150 MPa compared to conventional concrete mixes typically ranging from 20 to 40 MPa. The dense microstructure and fiber reinforcement in UHPC improve durability, abrasion resistance, and tensile strength, making it ideal for advanced construction applications requiring superior mechanical performance and longevity.

3D Printable UHPC

Ultra-High Performance Concrete (UHPC) offers superior compressive strength exceeding 150 MPa and exceptional durability compared to conventional concrete mixes typically ranging from 20 to 40 MPa, making it ideal for 3D printing complex structural components with enhanced precision and reduced material waste. The tailored rheological properties of 3D printable UHPC ensure optimal buildability and layer adhesion, enabling innovative architectural designs and faster construction cycles in infrastructure and building applications.

Concrete Mix vs Ultra-High Performance Concrete Infographic

industrydif.com

industrydif.com