Scaffolding provides temporary external support during construction, enabling safe access and stability for workers while assembling or repairing structures. Exoskeleton support, on the other hand, involves wearable technology that enhances a worker's strength and endurance, reducing physical strain and improving productivity on site. Choosing between scaffolding and exoskeleton support depends on the specific project requirements, safety considerations, and efficiency goals.

Table of Comparison

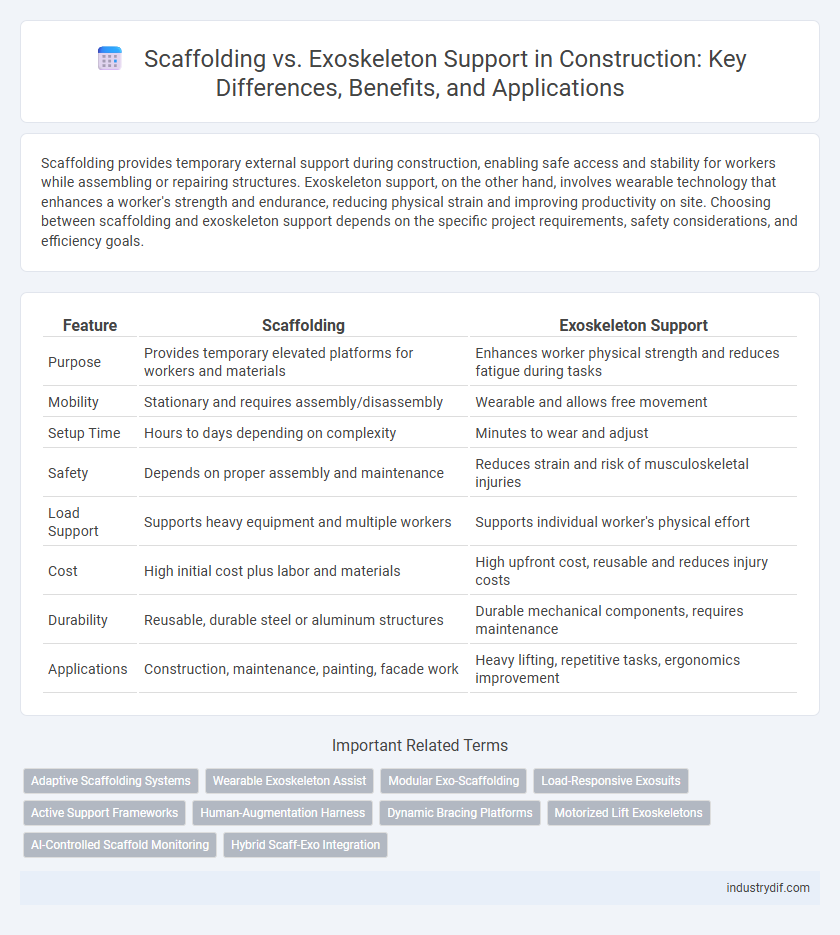

| Feature | Scaffolding | Exoskeleton Support |

|---|---|---|

| Purpose | Provides temporary elevated platforms for workers and materials | Enhances worker physical strength and reduces fatigue during tasks |

| Mobility | Stationary and requires assembly/disassembly | Wearable and allows free movement |

| Setup Time | Hours to days depending on complexity | Minutes to wear and adjust |

| Safety | Depends on proper assembly and maintenance | Reduces strain and risk of musculoskeletal injuries |

| Load Support | Supports heavy equipment and multiple workers | Supports individual worker's physical effort |

| Cost | High initial cost plus labor and materials | High upfront cost, reusable and reduces injury costs |

| Durability | Reusable, durable steel or aluminum structures | Durable mechanical components, requires maintenance |

| Applications | Construction, maintenance, painting, facade work | Heavy lifting, repetitive tasks, ergonomics improvement |

Introduction to Scaffolding and Exoskeleton Support

Scaffolding provides temporary, adjustable platforms for workers and materials during construction, ensuring safety at various heights and facilitating access to different building sections. Exoskeleton support involves wearable mechanical frameworks that reduce worker fatigue and enhance physical strength by distributing loads during labor-intensive tasks. Both methods improve efficiency and safety, but scaffolding offers structural elevation, while exoskeletons directly assist individual mobility and endurance.

Defining Scaffolding in Construction

Scaffolding in construction refers to a temporary structure made of metal pipes or wooden planks designed to support workers and materials during building, maintenance, or repair projects. It provides a stable and safe platform at various heights, facilitating access to hard-to-reach areas without permanent modifications to the building structure. Unlike exoskeleton support systems, scaffolding is versatile and widely used for short-term applications across diverse construction sites.

Understanding Exoskeleton Support Systems

Exoskeleton support systems in construction offer enhanced worker safety and efficiency by providing powered or passive mechanical assistance to reduce physical strain during heavy lifting and repetitive tasks. Unlike traditional scaffolding, exoskeletons are wearable devices that support posture and increase endurance, thus minimizing musculoskeletal injuries on job sites. Integration of exoskeleton technology improves productivity while maintaining compliance with occupational health standards.

Key Components and Materials Used

Scaffolding primarily consists of modular metal tubes, couplers, and wooden or metal platforms designed for temporary worker support and material handling during construction. Exoskeleton support systems incorporate lightweight carbon fiber or aluminum frames with adjustable joints and straps aimed at enhancing worker strength and reducing fatigue. While scaffolding relies on rigid structural assemblies, exoskeletons use ergonomic materials engineered for mobility and load distribution in physically demanding tasks.

Safety Considerations and Compliance

Scaffolding provides temporary platforms that require rigorous inspection and adherence to OSHA standards to ensure worker safety and prevent falls or structural failure. Exoskeleton support enhances physical safety by reducing worker fatigue and musculoskeletal injuries, with compliance centered on ergonomic regulations and personal protective equipment integration. Both methods demand strict compliance with construction safety codes and regular training to mitigate risks on-site.

Installation and Dismantling Procedures

Scaffolding installation involves assembling modular components like tubes, boards, and couplers to create temporary platforms, often requiring manual labor and precise alignment for safety compliance. Exoskeleton support systems are typically integrated with wearables that assist workers during installation and dismantling by reducing physical strain and enhancing mobility, minimizing setup time. Dismantling scaffolding demands systematic disassembly in reverse order to maintain structural integrity, whereas exoskeleton supports can be quickly removed as part of personal protective equipment protocols.

Cost Comparison: Scaffolding vs Exoskeleton Support

Scaffolding typically involves lower initial costs but higher labor and material expenses over time, especially for complex or tall structures. Exoskeleton support systems require a higher upfront investment due to advanced technology and specialized equipment but can reduce labor costs and increase efficiency on long-term projects. Evaluating project scale and duration is crucial to determine the most cost-effective solution between scaffolding and exoskeleton support in construction.

Applications in Modern Construction Projects

Scaffolding provides temporary access and support for workers during building construction, renovation, and maintenance, ensuring safety and efficiency at various heights. Exoskeleton support systems enhance worker strength and reduce fatigue by augmenting physical capabilities, particularly in tasks involving heavy lifting and repetitive motions. Modern construction projects integrate scaffolding for structural access while deploying exoskeletons to improve labor productivity and minimize injury risk on-site.

Advantages and Limitations of Each System

Scaffolding provides versatile and cost-effective temporary support for construction projects, enabling easy access to various work heights but requires extensive setup time and regular inspections to ensure safety. Exoskeleton support systems enhance worker ergonomics and reduce fatigue by augmenting physical strength, yet they involve higher initial investment and may limit mobility in complex tasks. Selecting between scaffolding and exoskeleton support depends on project scale, budget constraints, and specific safety or accessibility requirements.

Future Trends in Construction Support Solutions

Future trends in construction support solutions emphasize the integration of advanced materials and smart technologies to enhance scaffolding and exoskeleton support systems. Lightweight, high-strength composites and sensor-embedded scaffolding improve safety and efficiency, while exoskeletons with adaptive robotics offer workers enhanced mobility and load-bearing capabilities. The convergence of IoT, AI, and wearable tech drives innovation, reducing construction site injuries and optimizing project timelines.

Related Important Terms

Adaptive Scaffolding Systems

Adaptive scaffolding systems offer dynamic load-bearing capabilities and real-time structural adjustments, outperforming traditional exoskeleton supports in flexibility and safety under variable construction loads. These intelligent frameworks integrate sensor technology and automated controls to optimize stability, minimize material use, and accelerate assembly times on complex construction sites.

Wearable Exoskeleton Assist

Wearable exoskeleton assist technology in construction enhances worker safety and productivity by reducing physical strain during heavy lifting and repetitive tasks, outperforming traditional scaffolding in mobility and ergonomic support. Integrating powered exoskeletons improves endurance and decreases injury risk, driving innovation in industrial site safety protocols and labor efficiency.

Modular Exo-Scaffolding

Modular Exo-Scaffolding combines the stability of traditional scaffolding with the mobility of an exoskeleton, enabling safer and more efficient access to elevated construction sites. This innovative system reduces setup time by up to 40% while enhancing worker ergonomics and load-bearing capacity compared to conventional scaffolding or standalone exoskeletons.

Load-Responsive Exosuits

Load-responsive exosuits in construction enhance worker safety and efficiency by adapting to varying load conditions, reducing physical strain compared to traditional scaffolding that remains static and requires extensive setup. These exoskeleton supports offer dynamic, ergonomic assistance, enabling prolonged labor with improved posture and reduced risk of musculoskeletal injuries on-site.

Active Support Frameworks

Active support frameworks in construction utilize scaffolding to provide temporary, adjustable platforms ensuring worker safety and structural stability during building phases. Exoskeleton supports enhance human physical capacity through wearable mechanical systems, reducing fatigue and injury risks while promoting efficiency on-site.

Human-Augmentation Harness

Human-augmentation harnesses integrated into scaffolding provide enhanced ergonomic support, reducing worker fatigue and increasing safety on construction sites by distributing load and improving mobility. Exoskeleton support systems offer advanced biomechanical assistance, enabling construction workers to lift heavy materials with less strain and minimizing the risk of musculoskeletal injuries.

Dynamic Bracing Platforms

Dynamic bracing platforms in scaffolding provide adjustable, temporary support to stabilize structures during construction, while exoskeleton support offers permanent, integrated reinforcement enhancing load distribution and worker safety. Scaffolding's modular design allows for flexible bracing configurations, whereas exoskeleton systems use engineered frameworks to reduce structural stress and improve seismic resistance.

Motorized Lift Exoskeletons

Motorized lift exoskeletons enhance worker mobility and reduce fatigue by providing powered support during heavy lifting and repetitive tasks in construction, significantly improving safety and efficiency compared to traditional scaffolding which offers static, external support without mobility assistance. These wearable robotic suits integrate sensors and actuators to amplify human strength, enabling prolonged work durations at heights while minimizing musculoskeletal injuries.

AI-Controlled Scaffold Monitoring

AI-controlled scaffold monitoring enhances safety and efficiency on construction sites by providing real-time structural integrity analysis and automated hazard detection for both traditional scaffolding and exoskeleton support systems. Integration of machine learning algorithms enables predictive maintenance and dynamic load management, reducing risks associated with human error and material failure.

Hybrid Scaff-Exo Integration

Hybrid scaff-exo integration merges traditional scaffolding systems with advanced exoskeleton support to enhance worker safety and efficiency on construction sites. This approach leverages the structural stability of scaffolds with the ergonomic benefits of wearable exoskeletons, reducing physical strain and minimizing fall risks during elevated tasks.

Scaffolding vs Exoskeleton Support Infographic

industrydif.com

industrydif.com