Body armor provides reliable, rigid protection against ballistic threats by dispersing impact forces over a solid surface, making it ideal for consistent, high-risk situations. Liquid armor offers flexibility and lightweight comfort by hardening upon impact, allowing for greater mobility without sacrificing defense capabilities. Choosing between body armor and liquid armor depends on balancing protection level, weight, and wearer agility in various defense scenarios.

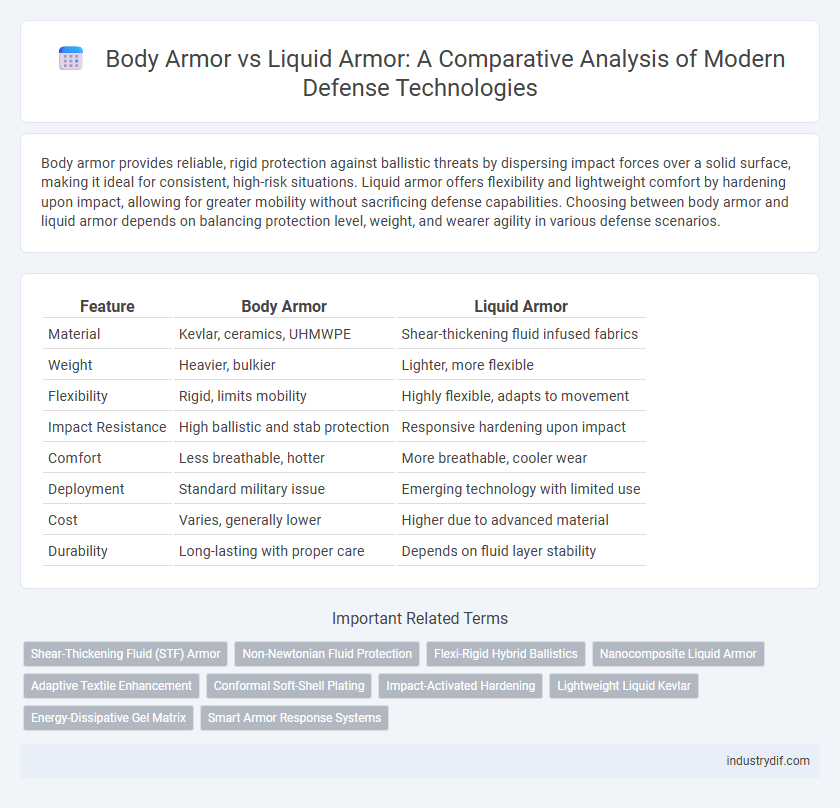

Table of Comparison

| Feature | Body Armor | Liquid Armor |

|---|---|---|

| Material | Kevlar, ceramics, UHMWPE | Shear-thickening fluid infused fabrics |

| Weight | Heavier, bulkier | Lighter, more flexible |

| Flexibility | Rigid, limits mobility | Highly flexible, adapts to movement |

| Impact Resistance | High ballistic and stab protection | Responsive hardening upon impact |

| Comfort | Less breathable, hotter | More breathable, cooler wear |

| Deployment | Standard military issue | Emerging technology with limited use |

| Cost | Varies, generally lower | Higher due to advanced material |

| Durability | Long-lasting with proper care | Depends on fluid layer stability |

Overview of Body Armor and Liquid Armor Technologies

Body armor traditionally relies on rigid materials such as Kevlar, ceramic plates, and ultra-high-molecular-weight polyethylene to provide ballistic protection against projectiles and shrapnel. Liquid armor technology integrates shear thickening fluids within flexible fabrics, enhancing impact resistance by instantly solidifying upon high-velocity impact to disperse energy more effectively. Emerging advancements in liquid armor aim to combine lightweight flexibility with superior blunt force protection, offering promising alternatives to conventional rigid armor systems.

Historical Evolution of Protective Armor in Defense

Body armor has evolved from rudimentary materials like leather and metal plates used by ancient warriors to advanced composites such as Kevlar and ultra-high-molecular-weight polyethylene in modern military applications. Liquid armor technology, developed in the 21st century, incorporates shear-thickening fluids embedded in fabric, providing enhanced flexibility and improved impact resistance over traditional armor. This progression reflects ongoing innovations aimed at balancing protection, mobility, and lightweight design for defense personnel.

Material Composition: Traditional vs. Liquid Armor

Traditional body armor primarily utilizes multiple layers of woven aramid fibers such as Kevlar, providing ballistic resistance through fiber strength and energy dispersion. Liquid armor incorporates shear-thickening fluids combined with flexible substrates like Kevlar or nylon, enhancing impact resistance by stiffening instantly upon high-velocity strikes. The integration of non-Newtonian fluids in liquid armor offers lightweight protection with improved flexibility compared to the denser, rigid construction of traditional ballistic vests.

Mechanisms of Protection: How Each Armor Works

Body armor uses layers of high-strength fibers, such as Kevlar or UHMWPE, to absorb and disperse the kinetic energy from ballistic impacts, preventing penetration by distributing force across a wider area. Liquid armor incorporates shear-thickening fluids that remain flexible under normal movement but instantly solidify upon impact, increasing resistance and reducing blunt force trauma. The key difference lies in the dynamic response of liquid armor's materials compared to the static, multi-layered fiber structure of traditional body armor.

Weight, Flexibility, and Mobility Comparison

Liquid armor offers superior flexibility and reduced weight compared to traditional body armor, enhancing soldier mobility in combat situations. Conventional body armor relies on rigid plates that provide high ballistic protection but often compromise agility due to their bulk and weight. Advances in shear-thickening fluids used in liquid armor absorb impact effectively while maintaining lightweight, allowing for greater ease of movement and endurance during extended missions.

Ballistic Resistance and Performance Metrics

Body armor traditionally relies on layered fabrics such as Kevlar to absorb and disperse ballistic energy, providing proven resistance against handgun rounds and some rifle calibers. Liquid armor utilizes shear-thickening fluids integrated into soft materials, significantly enhancing flexibility while dynamically hardening upon impact to improve ballistic resistance without sacrificing comfort. Performance metrics indicate liquid armor offers superior multi-hit capability and weight reduction, potentially exceeding conventional armor in blunt force trauma mitigation and durability under varied threat levels.

Cost Analysis: Manufacturing and Maintenance

Manufacturing body armor involves established processes using materials like Kevlar, resulting in moderate production costs and scalable output, while liquid armor, based on shear-thickening fluids, requires advanced technology and composite layering, significantly raising manufacturing expenses. Maintenance for traditional body armor is relatively straightforward, involving periodic inspections and replacement due to wear, whereas liquid armor demands more specialized care to preserve fluid integrity and performance over time. Cost analysis favors standard body armor for budget-conscious defense procurement, but liquid armor's superior flexibility and enhanced protection may justify higher upfront and maintenance investments in critical operational scenarios.

Adoption and Use Cases in Modern Defense Forces

Modern defense forces increasingly adopt liquid armor technologies alongside traditional body armor to enhance soldier protection and mobility. Liquid armor, utilizing shear-thickening fluids, offers superior flexibility and impact resistance in roles requiring agility such as special operations and reconnaissance. Conventional body armor remains prevalent for frontline infantry due to its established ballistic protection and extensive battlefield validation.

Limitations and Challenges of Both Armor Types

Body armor faces limitations such as weight and rigidity, which can restrict mobility and cause fatigue during prolonged use, while liquid armor challenges include durability and activation speed under impact. Both armor types struggle with balancing protection levels against various threats, like ballistic and stab resistance, without compromising wearer comfort. Advances in materials science are needed to overcome issues such as multi-hit performance degradation in conventional body armor and the scalability and cost-effectiveness of liquid armor technologies.

Future Trends in Personal Protective Equipment

Advancements in personal protective equipment emphasize the integration of body armor and liquid armor technologies, enhancing flexibility and impact resistance for military and law enforcement personnel. Liquid armor, utilizing shear-thickening fluids, offers adaptive protection that remains lightweight while hardening upon impact, addressing mobility challenges faced by traditional body armor. Future trends prioritize hybrid systems combining rigid ballistic materials with liquid armor layers, improving coverage and comfort without compromising survivability on the battlefield.

Related Important Terms

Shear-Thickening Fluid (STF) Armor

Shear-Thickening Fluid (STF) armor enhances traditional body armor by incorporating fluids that harden instantaneously upon impact, providing superior flexibility and increased ballistic protection without compromising mobility. This technology allows for lighter, more comfortable protective gear while maintaining high resistance to penetration from shrapnel and bullets.

Non-Newtonian Fluid Protection

Body armor utilizing non-Newtonian fluid protection maximizes impact resistance by hardening upon sudden force, offering superior flexibility and weight reduction compared to traditional rigid plates. Liquid armor adapts dynamically to varying threat levels, improving mobility for military personnel while maintaining high ballistic and stab protection standards.

Flexi-Rigid Hybrid Ballistics

Flexi-rigid hybrid ballistics combines the flexibility of soft body armor with the high-impact resistance of liquid armor technologies, enhancing wearer mobility without compromising protection against ballistic threats. This hybrid approach leverages shear-thickening fluids that harden upon impact alongside rigid ballistic plates, offering advanced multi-threat defense in modern military and law enforcement applications.

Nanocomposite Liquid Armor

Nanocomposite liquid armor combines advanced nanomaterials and shear-thickening fluids to provide superior impact resistance and flexibility compared to traditional body armor, enhancing mobility without compromising protection. Its unique nanoscale structure absorbs and disperses kinetic energy more efficiently, making it a transformative solution for military and law enforcement personnel seeking lightweight and adaptive protective gear.

Adaptive Textile Enhancement

Body armor traditionally relies on rigid plates for ballistic protection, whereas liquid armor incorporates shear-thickening fluids that harden upon impact, enhancing flexibility and comfort. Adaptive textile enhancement through liquid armor technology offers superior mobility and rapid response to threats by dynamically adjusting stiffness during combat scenarios.

Conformal Soft-Shell Plating

Conformal Soft-Shell Plating in body armor offers enhanced flexibility and reduced weight compared to traditional rigid plates, allowing for greater mobility and comfort in high-risk defense operations. Liquid armor, utilizing shear-thickening fluids, complements this by providing adaptive protection that hardens upon impact, creating a dynamic defense system optimized for diverse combat scenarios.

Impact-Activated Hardening

Impact-activated hardening in body armor utilizes shear-thickening fluids that remain flexible under normal conditions but instantly stiffen upon high-velocity impacts, providing enhanced protection and mobility. Liquid armor leverages this technology to offer superior trauma resistance by dynamically dispersing energy, outperforming traditional rigid plates in weight and adaptability.

Lightweight Liquid Kevlar

Lightweight Liquid Kevlar body armor integrates nanotechnology to enhance ballistic protection while significantly reducing weight compared to traditional Kevlar vests, offering superior flexibility and comfort for military personnel. This advanced liquid armor hardens upon impact, dispersing energy efficiently to protect against bullets and shrapnel, making it a cutting-edge solution in personal defense gear.

Energy-Dissipative Gel Matrix

Energy-dissipative gel matrices in liquid armor provide superior impact absorption by dispersing kinetic energy across a flexible, shear-thickening medium, enhancing wearer mobility compared to traditional rigid body armor. Unlike conventional ballistic plates, this gel matrix adapts dynamically to multiple threat levels, offering lightweight protection ideal for evolving defense environments.

Smart Armor Response Systems

Smart armor response systems integrate body armor and liquid armor technologies to enhance adaptive protection against ballistic and blunt force threats. Liquid armor's shear-thickening fluids solidify upon impact to distribute force, while embedded sensors in smart systems analyze and respond in real-time, optimizing defense based on threat type and intensity.

Body Armor vs Liquid Armor Infographic

industrydif.com

industrydif.com