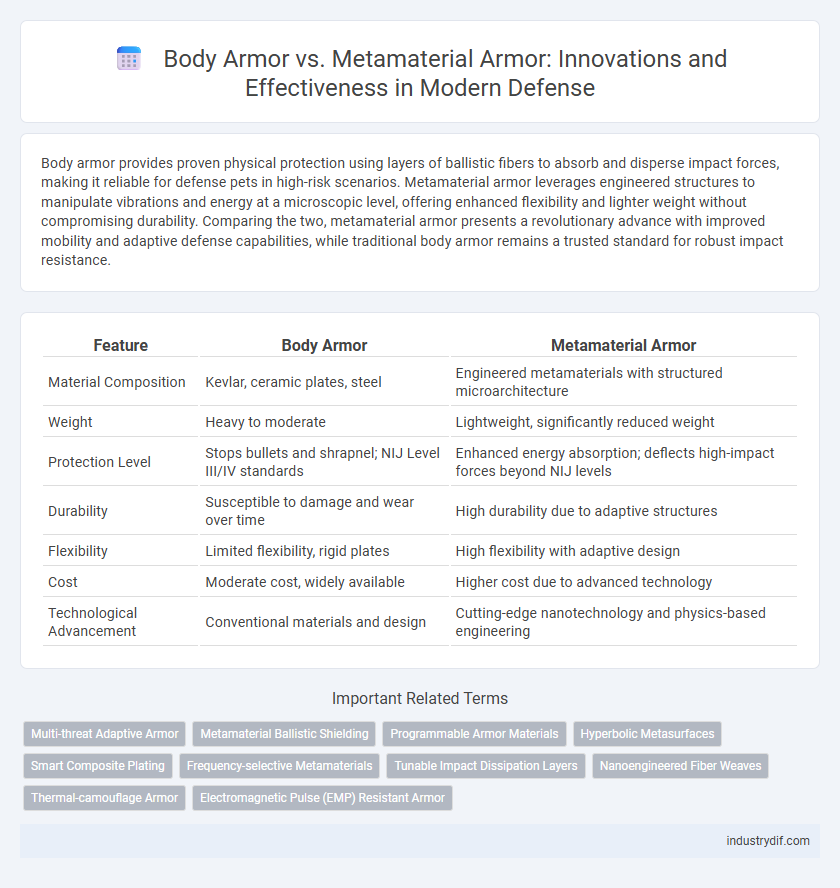

Body armor provides proven physical protection using layers of ballistic fibers to absorb and disperse impact forces, making it reliable for defense pets in high-risk scenarios. Metamaterial armor leverages engineered structures to manipulate vibrations and energy at a microscopic level, offering enhanced flexibility and lighter weight without compromising durability. Comparing the two, metamaterial armor presents a revolutionary advance with improved mobility and adaptive defense capabilities, while traditional body armor remains a trusted standard for robust impact resistance.

Table of Comparison

| Feature | Body Armor | Metamaterial Armor |

|---|---|---|

| Material Composition | Kevlar, ceramic plates, steel | Engineered metamaterials with structured microarchitecture |

| Weight | Heavy to moderate | Lightweight, significantly reduced weight |

| Protection Level | Stops bullets and shrapnel; NIJ Level III/IV standards | Enhanced energy absorption; deflects high-impact forces beyond NIJ levels |

| Durability | Susceptible to damage and wear over time | High durability due to adaptive structures |

| Flexibility | Limited flexibility, rigid plates | High flexibility with adaptive design |

| Cost | Moderate cost, widely available | Higher cost due to advanced technology |

| Technological Advancement | Conventional materials and design | Cutting-edge nanotechnology and physics-based engineering |

Introduction to Modern Protective Armor in Defense

Modern protective armor in defense integrates advanced materials to enhance soldier survivability on the battlefield. Traditional body armor relies on layers of Kevlar and ceramics to absorb and disperse ballistic impact, whereas metamaterial armor employs engineered structures designed at the microscopic level to manipulate mechanical waves for superior energy dissipation. Innovations in metamaterials promise lighter, more flexible armor systems with enhanced resistance against high-velocity projectiles and blasts compared to conventional body armor solutions.

Defining Body Armor: Traditional Materials and Capabilities

Traditional body armor predominantly utilizes materials such as Kevlar, ceramic plates, and high-strength polyethylene to provide ballistic protection against bullets, shrapnel, and blunt force trauma. These materials offer proven capabilities in dispersing impact energy and resisting penetration, but often come with limitations in weight, flexibility, and multi-threat adaptability. Conventional body armor prioritizes durability and coverage while balancing wearer mobility and comfort on the battlefield.

Metamaterial Armor: Emerging Technologies and Concepts

Metamaterial armor employs engineered structures at the nanoscale to manipulate electromagnetic waves and mechanical properties, offering enhanced ballistic resistance and reduced weight compared to traditional body armor. These advanced materials absorb and disperse kinetic energy more efficiently, improving soldier mobility and protection against modern threats such as high-velocity projectiles and blast waves. Ongoing research in metamaterial armor integrates concepts from materials science and physics to develop flexible, adaptive armor systems with potential applications across military and defense sectors.

Comparative Protection: Ballistics and Impact Resistance

Body armor traditionally relies on layered Kevlar or ceramic plates to absorb and distribute ballistic impacts, effectively stopping handgun rounds and shrapnel but often struggles against high-velocity rifle rounds and blunt force trauma. Metamaterial armor enhances protection by utilizing engineered materials designed at the microscopic level, which dissipate energy more efficiently and offer superior impact resistance while maintaining lighter weight and flexibility. Studies indicate metamaterial armor can outperform conventional body armor in resisting multi-hit ballistic impacts and reducing trauma from blunt forces, marking a significant advancement in defensive capabilities.

Flexibility and Mobility: Ergonomics in Armor Design

Metamaterial armor significantly enhances flexibility and mobility compared to traditional body armor by incorporating advanced engineered structures that adapt to body movements. Ergonomic design in metamaterial armor reduces fatigue and improves soldier performance by providing lightweight protection without compromising coverage. The integration of metamaterials enables better articulation and less restriction, critical for dynamic combat environments.

Weight and Comfort: Operational Implications

Body armor traditionally relies on heavy ballistic materials that can restrict mobility and increase fatigue during extended missions, impacting operational efficiency. Metamaterial armor offers significant weight reduction while maintaining protection levels, enhancing soldier comfort and endurance in diverse combat environments. This advancement enables greater agility and sustained performance, crucial for mission success in modern defense operations.

Adaptability to Evolving Threats

Body armor traditionally relies on rigid materials such as Kevlar and ceramics, providing effective protection against conventional ballistic threats but often lacking flexibility against emerging high-velocity projectiles and advanced explosives. Metamaterial armor incorporates engineered structures that can dynamically alter their mechanical properties, enabling enhanced adaptability to evolving threats by dissipating energy more efficiently and resisting a broader spectrum of impacts. This innovative technology offers a significant advantage in modern defense contexts by potentially reducing weight while improving protective capabilities against both known and novel attack vectors.

Cost Analysis: Production, Procurement, and Lifecycle

Body armor production costs vary widely based on materials such as Kevlar and ceramic plates, with metamaterial armor often requiring advanced fabrication techniques that increase initial manufacturing expenses. Procurement expenses must consider not only purchase price but also scalability and supply chain complexity; metamaterial armor currently incurs higher procurement costs due to limited suppliers and novel production processes. Lifecycle costs for both armor types include maintenance, replacement frequency, and durability, where metamaterial armor shows potential for longer service life and reduced maintenance, potentially offsetting its higher upfront investment.

Adoption Challenges and Future Trends

Body armor faces significant adoption challenges due to weight constraints and limited flexibility, restricting soldier mobility and endurance. Metamaterial armor, leveraging advanced nanostructures for enhanced impact absorption and reduced mass, shows promising potential but struggles with high production costs and scalability issues. Future trends indicate a shift towards hybrid solutions that integrate metamaterials with traditional ballistic fibers to optimize protection efficiency and operational adaptability.

Final Assessment: Body Armor vs Metamaterial Armor in Defense

Metamaterial armor outperforms traditional body armor by providing enhanced ballistic resistance and weight reduction, crucial for modern defense applications. Its engineered structure allows for superior energy dispersion and impact absorption compared to conventional Kevlar or ceramic composites. Adoption of metamaterial armor could revolutionize soldier protection by combining advanced durability with improved mobility.

Related Important Terms

Multi-threat Adaptive Armor

Multi-threat adaptive armor leveraging metamaterials offers superior defense capabilities compared to traditional body armor by dynamically altering its structural properties to counter ballistic, blast, and stab threats simultaneously. This innovative approach integrates tunable metamaterial layers that enhance energy absorption, reduce weight, and improve wearer mobility while maintaining high protection levels against diverse combat scenarios.

Metamaterial Ballistic Shielding

Metamaterial ballistic shielding leverages engineered microstructures to achieve superior impact absorption and energy dispersion compared to traditional body armor, providing enhanced protection against high-velocity projectiles. Innovations in metamaterial design enable lighter, more flexible armor solutions that maintain structural integrity while reducing wearer fatigue, revolutionizing personal defense capabilities.

Programmable Armor Materials

Programmable armor materials leverage metamaterial technology to dynamically adapt their structural properties, providing enhanced ballistic resistance and impact dispersion compared to conventional body armor. These smart materials integrate sensors and responsive elements that allow real-time modulation of stiffness and flexibility, significantly improving soldier protection and mobility on the battlefield.

Hyperbolic Metasurfaces

Body armor embedded with hyperbolic metasurfaces outperforms traditional ballistic vests by manipulating electromagnetic waves to dissipate impact energy more efficiently, significantly enhancing protection against high-velocity projectiles. This advanced metamaterial armor leverages anisotropic permittivity to create subwavelength scale energy redirection, reducing penetration risks and increasing battlefield survivability.

Smart Composite Plating

Smart composite plating in metamaterial armor offers advanced structural adaptability and enhanced ballistic resistance compared to traditional body armor, utilizing engineered materials that manipulate electromagnetic waves for superior impact dispersion. This innovation delivers lighter-weight protection with improved energy absorption and multi-threat defense capabilities, revolutionizing personal protection systems in modern military applications.

Frequency-selective Metamaterials

Frequency-selective metamaterials in body armor enable selective absorption and reflection of electromagnetic waves, significantly enhancing protection against radar-guided threats and electronic warfare compared to traditional ballistic materials. These advanced metamaterials provide tunable frequency responses and lightweight designs, improving situational awareness and survivability on the battlefield.

Tunable Impact Dissipation Layers

Tunable impact dissipation layers in metamaterial armor utilize adaptive microstructures to dynamically disperse kinetic energy, outperforming traditional body armor that relies on static, rigid materials for protection. These advanced layers provide enhanced flexibility, reduced weight, and customizable impact resistance, offering superior defense against ballistic and blunt force threats.

Nanoengineered Fiber Weaves

Nanoengineered fiber weaves in metamaterial armor offer superior ballistic resistance and enhanced flexibility compared to traditional body armor, enabling lighter and more durable protective gear for military applications. These advanced fibers provide exceptional energy dissipation and impact absorption at the nanoscale, significantly improving soldier mobility and survivability on the battlefield.

Thermal-camouflage Armor

Metamaterial armor significantly enhances thermal-camouflage capabilities by manipulating electromagnetic waves to reduce infrared signatures, outperforming traditional body armor that primarily offers ballistic protection without minimizing heat detection. This advanced thermal stealth technology in metamaterial armor provides critical advantages in modern defense by enabling soldiers to operate undetected in heat-sensitive surveillance environments.

Electromagnetic Pulse (EMP) Resistant Armor

Metamaterial armor offers superior protection against electromagnetic pulse (EMP) threats by leveraging engineered structures that can absorb and dissipate high-energy electromagnetic waves, whereas traditional body armor primarily protects against kinetic impacts but lacks inherent EMP resistance. Advances in metamaterial design enable effective shielding of sensitive electronics and personnel from EMP effects, making it a critical innovation for modern defense applications requiring electromagnetic resilience.

Body Armor vs Metamaterial Armor Infographic

industrydif.com

industrydif.com