Cold-pressed juice retains more nutrients and enzymes due to its gentle extraction process, making it a healthier option for pets. HPP (High Pressure Processing) juice undergoes a preservation method that extends shelf life without heat, maintaining freshness but slightly reducing some sensitive nutrients. Choosing between cold-pressed and HPP juice depends on prioritizing raw nutrition versus longer-lasting product safety for your pet.

Table of Comparison

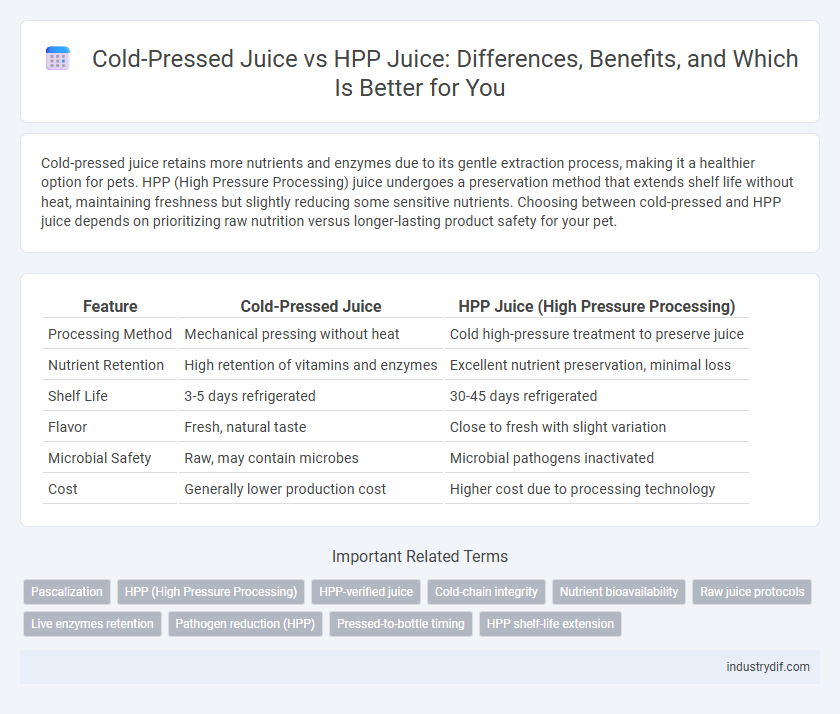

| Feature | Cold-Pressed Juice | HPP Juice (High Pressure Processing) |

|---|---|---|

| Processing Method | Mechanical pressing without heat | Cold high-pressure treatment to preserve juice |

| Nutrient Retention | High retention of vitamins and enzymes | Excellent nutrient preservation, minimal loss |

| Shelf Life | 3-5 days refrigerated | 30-45 days refrigerated |

| Flavor | Fresh, natural taste | Close to fresh with slight variation |

| Microbial Safety | Raw, may contain microbes | Microbial pathogens inactivated |

| Cost | Generally lower production cost | Higher cost due to processing technology |

Overview of Cold-Pressed Juice

Cold-pressed juice is produced by crushing and pressing fruits and vegetables to extract juice without heat, preserving more vitamins, enzymes, and nutrients compared to traditional juicing methods. This process maintains the fresh flavor and color of the juice while minimizing oxidation and nutrient degradation. Cold-pressed juices typically have a shorter shelf life due to minimal processing, distinguishing them from High Pressure Processing (HPP) juices that use pressure to extend preservation.

What is HPP (High Pressure Processing) Juice?

HPP (High Pressure Processing) juice is a cold-pressed juice that undergoes a non-thermal pasteurization method using high pressure to eliminate harmful bacteria while preserving nutrients and fresh taste. Unlike traditional heat pasteurization, HPP maintains the juice's vitamins, enzymes, and antioxidants by avoiding heat exposure. This advanced preservation technique extends shelf life without compromising the juice's natural flavor and health benefits.

Key Differences Between Cold-Pressed and HPP Juices

Cold-pressed juice is extracted by applying hydraulic pressure to fruits and vegetables, preserving more nutrients and enzymes due to minimal heat exposure. HPP (High Pressure Processing) juice undergoes cold-press extraction followed by high-pressure treatment to eliminate pathogens and extend shelf life without using heat. The key difference lies in HPP's added safety and longevity benefits, while cold-pressed juice emphasizes freshness and nutrient retention.

Nutritional Value: Cold-Pressed vs HPP Juices

Cold-pressed juice retains more nutrients and enzymes due to its low-heat extraction process, preserving vitamins like C and antioxidants critical for health. High Pressure Processing (HPP) juice also maintains nutritional value by using high pressure to eliminate pathogens while minimizing heat damage, yet it may slightly reduce some heat-sensitive nutrients. Both methods offer nutrient-rich juices, but cold-pressed juices typically provide a fresher, more nutrient-dense option for optimal vitamin retention.

Shelf Life and Storage Comparison

Cold-pressed juice typically has a shorter shelf life of 3 to 5 days when refrigerated due to minimal heat treatment, preserving nutrients but increasing perishability. HPP (High Pressure Processing) juice extends shelf life up to 30 to 45 days by using high pressure to eliminate pathogens without heat, maintaining freshness and nutritional quality longer. Storage for cold-pressed juice requires consistent refrigeration, while HPP juice can endure slightly fluctuating temperatures but still benefits from cold storage to maximize shelf stability.

Taste and Freshness: A Sensory Evaluation

Cold-pressed juice retains a vibrant, natural flavor profile due to minimal heat exposure during extraction, preserving delicate enzymes and nutrients that contribute to its fresh taste. High Pressure Processing (HPP) juice, while extending shelf life and ensuring safety, may exhibit slight alterations in flavor intensity and texture because of pressure-induced changes in cell structure. Sensory evaluations often reveal that cold-pressed juices deliver a more authentic, fresh-tasting experience compared to HPP juices, which can sometimes have a muted or modified flavor spectrum.

Safety and Microbial Control in Juice Processing

Cold-pressed juice retains more nutrients due to minimal heat exposure, but it requires strict hygiene and rapid refrigeration to prevent microbial growth. High Pressure Processing (HPP) uses intense pressure to inactivate pathogens and spoilage microorganisms without heat, significantly enhancing juice safety and extending shelf life. HPP is recognized for its superior microbial control, effectively eliminating bacteria like Listeria and E. coli while preserving fresh juice quality.

Environmental Impact of Juice Processing Methods

Cold-pressed juice production consumes less energy compared to High-Pressure Processing (HPP) because it relies on hydraulic presses instead of high-pressure machines, leading to a smaller carbon footprint. HPP juice processing requires significant electricity to maintain pressures up to 600 MPa, resulting in higher greenhouse gas emissions during production. Packaging materials and transportation emissions also influence the overall environmental impact, with cold-pressed juices often using minimal processing allowing for shorter supply chains and reduced waste.

Consumer Preferences: Trends and Insights

Consumer preferences reveal a growing demand for cold-pressed juice due to its perceived freshness and retention of natural nutrients, appealing to health-conscious buyers. HPP juice gains favor among consumers prioritizing longer shelf life and food safety without preservatives, aligning with convenience trends. Market data indicates a shift towards transparent labeling and clean ingredient lists, driving preference for both cold-pressed and HPP juices depending on lifestyle and consumption habits.

Cold-Pressed vs HPP Juice: Which Is Better for You?

Cold-pressed juice retains more nutrients and enzymes due to its extraction method using hydraulic pressure without heat, preserving vitamins like C and antioxidants. HPP (High Pressure Processing) juice offers extended shelf life and safety by using high pressure to eliminate pathogens without heat, but may slightly reduce some heat-sensitive nutrients compared to cold-pressed options. Choosing between cold-pressed and HPP juice depends on prioritizing nutrient retention versus longer shelf stability and food safety.

Related Important Terms

Pascalization

Cold-pressed juice retains maximum nutrients and enzymes by using slow hydraulic pressure to extract juice without heat, while HPP (High Pressure Processing) juice undergoes Pascalization, which uses intense pressure to eliminate pathogens and extend shelf life without compromising flavor or nutritional value. Pascalization in HPP juice ensures food safety by inactivating bacteria and viruses, making it a superior method for preserving freshness compared to traditional pasteurization.

HPP (High Pressure Processing)

HPP juice retains more nutrients and extends shelf life without heat, preserving flavor and freshness better than traditional cold-pressed juice. This High Pressure Processing method effectively eliminates harmful bacteria while maintaining essential vitamins and antioxidants.

HPP-verified juice

HPP-verified juice undergoes High Pressure Processing, preserving nutrients and extending shelf life without heat, maintaining fresh flavor and enhancing food safety by eliminating pathogens. Compared to cold-pressed juice, HPP juice offers superior microbial stability and longer storage options while retaining essential vitamins and antioxidants.

Cold-chain integrity

Cold-pressed juice maintains cold-chain integrity by being quickly chilled immediately after extraction, preserving nutrients and flavor without heat exposure. In contrast, HPP juice undergoes high-pressure processing, which requires strict cold-chain management before and after treatment to prevent microbial growth and extend shelf life.

Nutrient bioavailability

Cold-pressed juice retains higher levels of vitamins, enzymes, and antioxidants due to minimal heat exposure during extraction, enhancing nutrient bioavailability. High Pressure Processing (HPP) juice, while extending shelf life and reducing pathogens, can cause slight nutrient degradation but preserves more bioactive compounds than pasteurized juices.

Raw juice protocols

Cold-pressed juice retains maximum nutrients by using hydraulic pressure to extract juice without heat, preserving enzymes and raw food qualities effectively. HPP (High Pressure Processing) juice undergoes intense pressure to eliminate pathogens while maintaining freshness, but may slightly alter enzyme activity compared to raw cold-pressed juice.

Live enzymes retention

Cold-pressed juice retains more live enzymes due to minimal heat exposure during extraction, preserving vital nutrients and probiotics that promote digestion and overall health. High Pressure Processing (HPP) juice, while extending shelf life by eliminating pathogens, may reduce enzyme activity as the intense pressure can denature some heat-sensitive enzymes.

Pathogen reduction (HPP)

High Pressure Processing (HPP) juice offers superior pathogen reduction by utilizing intense pressure to inactivate harmful bacteria, viruses, and molds without heat, preserving nutritional quality and flavor. In contrast, cold-pressed juice relies solely on mechanical extraction, making it more susceptible to microbial contamination and shorter shelf life.

Pressed-to-bottle timing

Cold-pressed juice is extracted through hydraulic pressure and typically bottled within hours to preserve maximum nutrients and fresh flavor, while High Pressure Processing (HPP) juice undergoes intense pressure treatment after bottling, allowing a longer shelf life without heat but with slightly altered fresh taste. The pressed-to-bottle timing in cold-pressed juice emphasizes immediate bottling to minimize oxidation, whereas HPP juice relies on post-bottling preservation, balancing freshness with extended durability.

HPP shelf-life extension

HPP juice uses high-pressure processing to eliminate pathogens while preserving nutrients and freshness, significantly extending shelf life up to 45 days compared to 3 to 5 days for cold-pressed juice. This method maintains the juice's color and flavor without heat pasteurization, offering a safer and longer-lasting alternative for cold-pressed beverages.

Cold-pressed juice vs HPP juice Infographic

industrydif.com

industrydif.com