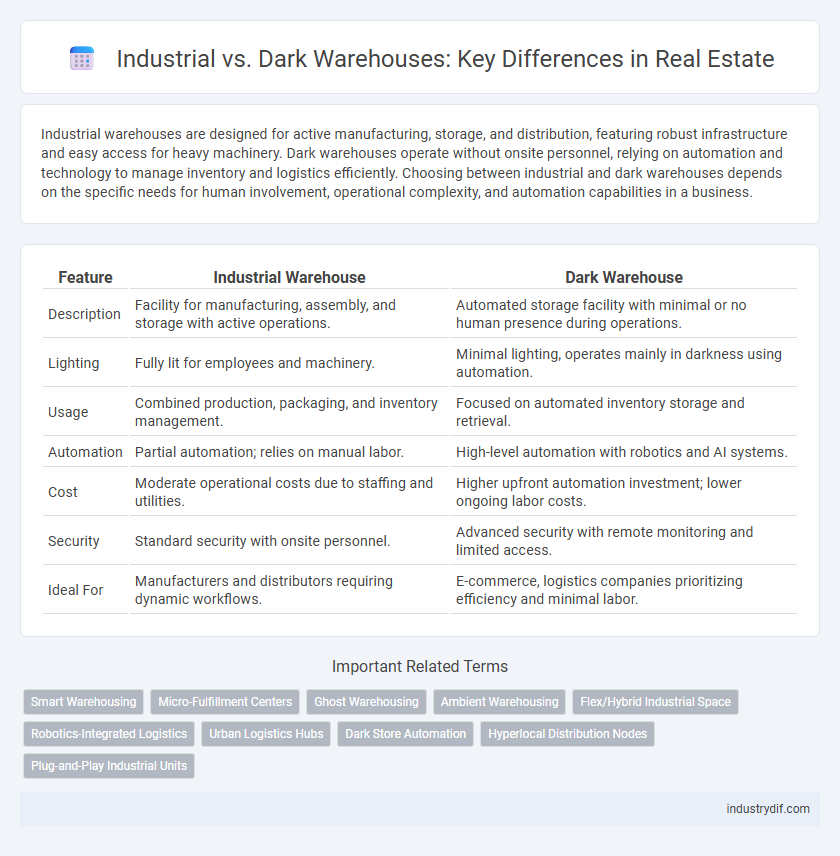

Industrial warehouses are designed for active manufacturing, storage, and distribution, featuring robust infrastructure and easy access for heavy machinery. Dark warehouses operate without onsite personnel, relying on automation and technology to manage inventory and logistics efficiently. Choosing between industrial and dark warehouses depends on the specific needs for human involvement, operational complexity, and automation capabilities in a business.

Table of Comparison

| Feature | Industrial Warehouse | Dark Warehouse |

|---|---|---|

| Description | Facility for manufacturing, assembly, and storage with active operations. | Automated storage facility with minimal or no human presence during operations. |

| Lighting | Fully lit for employees and machinery. | Minimal lighting, operates mainly in darkness using automation. |

| Usage | Combined production, packaging, and inventory management. | Focused on automated inventory storage and retrieval. |

| Automation | Partial automation; relies on manual labor. | High-level automation with robotics and AI systems. |

| Cost | Moderate operational costs due to staffing and utilities. | Higher upfront automation investment; lower ongoing labor costs. |

| Security | Standard security with onsite personnel. | Advanced security with remote monitoring and limited access. |

| Ideal For | Manufacturers and distributors requiring dynamic workflows. | E-commerce, logistics companies prioritizing efficiency and minimal labor. |

Understanding Industrial Warehouses

Industrial warehouses are designed to support manufacturing, assembly, and distribution operations with features like high ceilings, loading docks, and extensive electrical infrastructure. These spaces prioritize accessibility for heavy machinery and efficient movement of goods, often located near transportation hubs. Unlike dark warehouses, which are optimized for automated storage and minimal human presence, industrial warehouses require significant human interaction and operational flexibility.

Defining Dark Warehouses

Dark warehouses are industrial storage facilities designed for automated operations without on-site personnel, relying heavily on robotics and advanced technology to manage inventory. These warehouses optimize space utilization and reduce labor costs by enabling 24/7 operations with minimal human intervention. Unlike traditional industrial warehouses, dark warehouses emphasize efficiency and speed through automation, making them ideal for e-commerce and high-demand supply chains.

Key Differences Between Industrial and Dark Warehouses

Industrial warehouses typically feature active operations with personnel managing goods, equipped with loading docks and extensive lighting to facilitate continuous workflow. Dark warehouses operate with minimal or no human presence, relying heavily on automation and robotics under low-light or no-light conditions to optimize efficiency and reduce labor costs. The key differences lie in operational activity, technological reliance, and lighting conditions, which influence their strategic deployment in supply chain management.

Automation in Dark Warehouses

Dark warehouses are highly automated industrial facilities designed to operate without human presence, utilizing robotics and AI for tasks such as sorting, picking, and inventory management. In contrast to traditional industrial warehouses, dark warehouses significantly reduce labor costs and increase efficiency by optimizing automation technologies like automated guided vehicles (AGVs) and conveyor systems. This automation enables 24/7 operation, faster fulfillment rates, and enhanced accuracy, making dark warehouses a pivotal trend in modern supply chain logistics.

Operational Efficiency: Industrial vs Dark Warehouses

Industrial warehouses maximize operational efficiency through constant staffing, advanced automation, and real-time inventory management, ensuring seamless order fulfillment and maintenance. Dark warehouses, operating without on-site personnel, rely heavily on automated systems and robotics to reduce labor costs but may face challenges in immediate issue resolution and adaptability. Choosing between industrial and dark warehouses depends on balancing labor availability, operational agility, and technology investment to optimize supply chain performance.

Cost Implications of Warehouse Types

Industrial warehouses typically incur higher costs due to the need for advanced ventilation, lighting, and safety systems to support active operations, while dark warehouses reduce expenses by minimizing these utilities and relying on automation for storage and retrieval. The energy consumption in dark warehouses is significantly lower, leading to reduced operational costs, but initial investment in robotics and automated systems can be substantial. Businesses must weigh ongoing savings against upfront technology expenses when choosing between industrial and dark warehouse models.

Technology Integration in Modern Warehousing

Modern industrial warehouses leverage advanced technologies such as automation, IoT sensors, and AI-driven inventory management to optimize operational efficiency and real-time data analytics. Dark warehouses, designed for fully automated environments, integrate robotics and machine learning systems to facilitate unmanned, 24/7 operations, minimizing human intervention. The adoption of cutting-edge technology in both warehouse types enhances supply chain responsiveness, reduces errors, and drives cost-effective logistics solutions in contemporary real estate investments.

Security Measures in Industrial and Dark Warehouses

Industrial warehouses feature robust security measures including surveillance cameras, access control systems, and on-site personnel to prevent theft and unauthorized entry. Dark warehouses, often automated and unmanned, rely heavily on advanced security technologies like motion sensors, remote monitoring, and biometric access to safeguard inventory. Both warehouse types prioritize securing goods, but dark warehouses emphasize technology-driven solutions due to minimal human presence.

Sustainability Considerations

Industrial warehouses typically incorporate energy-efficient lighting, solar panels, and advanced HVAC systems to reduce carbon footprints, promoting sustainability in supply chain operations. Dark warehouses, designed for automated processes with minimal human presence, enable optimized energy consumption through precise climate control and reduced lighting needs, aligning with green building standards. Both warehouse types increasingly adopt sustainable materials and smart technologies to enhance environmental performance and comply with evolving regulatory frameworks.

Future Trends in Warehouse Management

Emerging technologies such as IoT sensors and AI-driven analytics are set to revolutionize industrial warehouses by enhancing inventory tracking, energy efficiency, and predictive maintenance. Dark warehouses, designed for fully automated, unmanned operations, are gaining traction as labor costs rise and e-commerce demands increase, enabling 24/7 productivity with minimal human intervention. The integration of sustainable energy solutions and advanced robotics will continue to shape the future of warehouse management, optimizing space utilization and reducing operational costs in both industrial and dark warehouse environments.

Related Important Terms

Smart Warehousing

Smart warehousing integrates advanced automation, IoT sensors, and AI-driven analytics to optimize inventory management and operational efficiency, distinguishing modern industrial warehouses from traditional dark warehouses that primarily serve as passive storage with minimal technology use. Industrial warehouses with smart systems enable real-time data monitoring and adaptive environments, enhancing supply chain responsiveness compared to dark warehouses, which often lack connectivity and automation features.

Micro-Fulfillment Centers

Micro-fulfillment centers leverage industrial warehouses for efficient inventory management and rapid order fulfillment, contrasting with dark warehouses that remain unstaffed and primarily serve as automated storage spaces. Utilizing industrial facilities for micro-fulfillment enhances supply chain speed and scalability, meeting the growing demand for last-mile delivery in e-commerce.

Ghost Warehousing

Ghost warehousing refers to underutilized or vacant industrial spaces that once thrived as dark warehouses, a type of facility operated without on-site staff using automated systems for 24/7 order fulfillment. These ghost warehouses indicate a shift in industrial real estate demand, highlighting the need for adaptive reuse strategies to revitalize dormant assets and accommodate evolving supply chain technologies.

Ambient Warehousing

Ambient warehousing refers to storage facilities maintained at standard room temperatures, optimizing the preservation of goods without the need for climate control systems common in cold storage. Unlike dark warehouses, which operate with minimal automation and human presence, ambient warehouses balance energy efficiency and accessibility, making them ideal for industrial logistics that require flexible handling of non-perishable products.

Flex/Hybrid Industrial Space

Flex industrial spaces combine the functionality of traditional warehouses with office and showroom areas, offering adaptable environments suited for a variety of commercial uses. Dark warehouses, characterized by their minimal lighting and large scale, are optimized for high-volume storage and distribution but lack the versatility of flex or hybrid industrial spaces.

Robotics-Integrated Logistics

Industrial warehouses equipped with advanced robotics systems enable real-time inventory management, automated sorting, and faster order fulfillment, driving efficiency in supply chains. Dark warehouses, operating fully autonomously without human presence, leverage robotics-integrated logistics to optimize space utilization and reduce labor costs while maintaining high throughput.

Urban Logistics Hubs

Industrial warehouses primarily support manufacturing and distribution processes with high ceilings, loading docks, and heavy machinery for urban logistics hubs, while dark warehouses operate without on-site staff, relying heavily on automation and robotics for efficient inventory management in tight city spaces. Urban logistics hubs benefit from dark warehouses' 24/7 operations and reduced labor costs, contrasting with industrial warehouses' versatility in handling bulky goods and direct shipment integration.

Dark Store Automation

Dark warehouses operate without on-site staff, leveraging advanced automation technologies such as robotics, AI-driven inventory management, and conveyor systems to streamline order fulfillment; industrial warehouses typically require human oversight and prioritize large-scale storage over rapid processing. Dark store automation increases efficiency and reduces operational costs, making these facilities ideal for e-commerce and just-in-time inventory models compared to conventional industrial warehouses.

Hyperlocal Distribution Nodes

Hyperlocal distribution nodes prioritize dark warehouses due to their efficiency in streamlining last-mile delivery with minimal overhead, unlike traditional industrial warehouses designed for bulk storage and manufacturing support. Dark warehouses facilitate faster inventory turnover and optimize urban logistics by reducing transit times and increasing accessibility within dense markets.

Plug-and-Play Industrial Units

Plug-and-play industrial units offer immediate operational readiness with pre-installed utilities and infrastructure, contrasting with traditional dark warehouses that require significant customization and setup before use. These turnkey solutions reduce downtime and accelerate business processes by providing flexible, scalable spaces tailored for manufacturing, logistics, and distribution needs.

Industrial vs Dark Warehouses Infographic

industrydif.com

industrydif.com