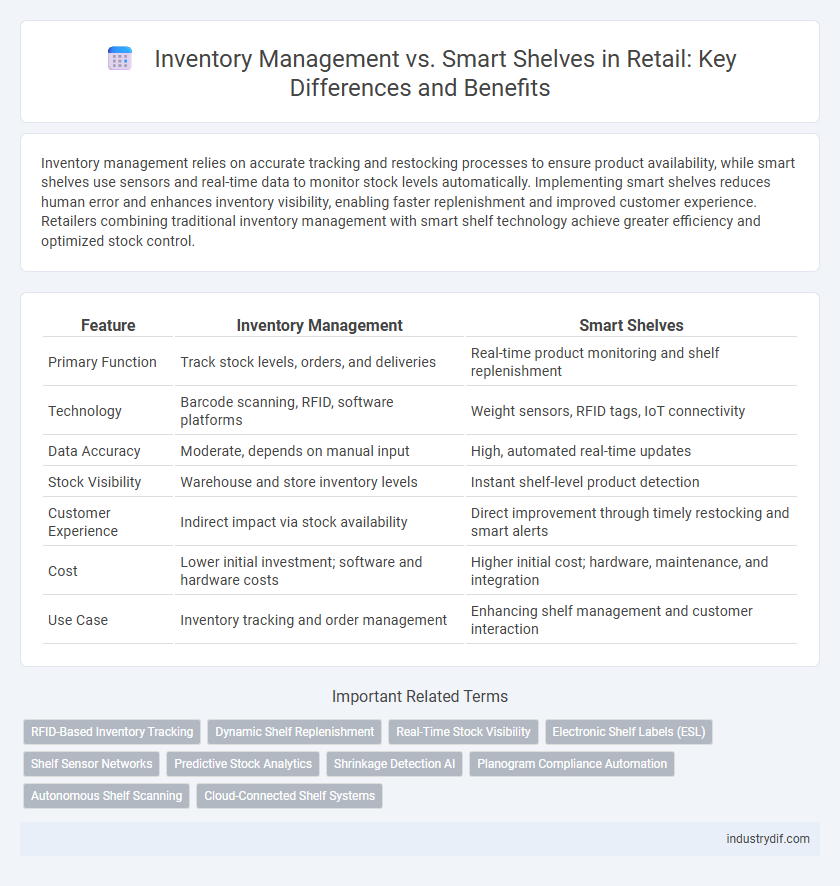

Inventory management relies on accurate tracking and restocking processes to ensure product availability, while smart shelves use sensors and real-time data to monitor stock levels automatically. Implementing smart shelves reduces human error and enhances inventory visibility, enabling faster replenishment and improved customer experience. Retailers combining traditional inventory management with smart shelf technology achieve greater efficiency and optimized stock control.

Table of Comparison

| Feature | Inventory Management | Smart Shelves |

|---|---|---|

| Primary Function | Track stock levels, orders, and deliveries | Real-time product monitoring and shelf replenishment |

| Technology | Barcode scanning, RFID, software platforms | Weight sensors, RFID tags, IoT connectivity |

| Data Accuracy | Moderate, depends on manual input | High, automated real-time updates |

| Stock Visibility | Warehouse and store inventory levels | Instant shelf-level product detection |

| Customer Experience | Indirect impact via stock availability | Direct improvement through timely restocking and smart alerts |

| Cost | Lower initial investment; software and hardware costs | Higher initial cost; hardware, maintenance, and integration |

| Use Case | Inventory tracking and order management | Enhancing shelf management and customer interaction |

Introduction to Retail Inventory Management

Retail inventory management involves tracking stock levels, orders, and sales to ensure optimal product availability and reduce carrying costs. Smart shelves integrate sensors and RFID technology to provide real-time inventory data, enabling accurate stock monitoring and automatic replenishment alerts. Combining traditional inventory management with smart shelves enhances accuracy, minimizes stockouts, and improves overall supply chain efficiency.

What Are Smart Shelves?

Smart shelves are advanced retail fixtures equipped with weight sensors, RFID technology, and digital displays to monitor inventory levels in real-time, reducing stockouts and enabling automated restocking alerts. Unlike traditional inventory management systems that rely on manual counts or periodic audits, smart shelves provide continuous, accurate data on product availability and customer interaction. Integrating smart shelves with inventory management software enhances supply chain efficiency, optimizes stock allocation, and improves overall retail operational performance.

Key Differences: Traditional vs Smart Shelf Inventory Management

Traditional inventory management relies on manual stock counts and static reorder points, often leading to delayed restocking and inaccuracies. Smart shelves use embedded sensors and real-time data analytics to automatically track product levels, reducing stockouts and improving replenishment efficiency. This technology integration enhances inventory visibility and streamlines supply chain operations compared to conventional methods.

Benefits of Classic Inventory Management Systems

Classic inventory management systems provide reliable tracking of stock levels, minimizing the risk of overstocking or stockouts through real-time data updates and automated reorder alerts. These systems enhance operational efficiency by streamlining procurement processes and improving demand forecasting accuracy. Integration with point-of-sale and supply chain platforms ensures seamless inventory visibility across multiple retail locations.

How Smart Shelves Revolutionize Retail

Smart shelves revolutionize retail by integrating RFID and IoT technologies to provide real-time inventory tracking, significantly reducing stockouts and overstock situations. These advanced shelves automatically update inventory levels, enabling accurate demand forecasting and streamlined restocking processes. Retailers benefit from improved product visibility and enhanced customer experience through personalized promotions and quicker checkout times.

Cost Implications: Inventory Systems vs Smart Shelves

Inventory management systems typically involve software and manual processes that can incur significant labor costs and require regular updates, whereas smart shelves use IoT sensors that reduce labor expenses by automating stock tracking. Smart shelves minimize stockouts and overstock situations by providing real-time inventory data, leading to cost savings in storage and lost sales. Although the initial investment in smart shelf technology can be higher, the long-term reduction in operational costs and improved inventory accuracy often justify the expense for retailers.

Real-Time Data: Traditional Methods vs Smart Shelf Technology

Inventory management relies heavily on periodic manual counts and static data, often leading to delays and inaccuracies in stock levels. Smart shelf technology integrates sensors and IoT devices to provide real-time data on product availability, enabling immediate adjustments and reducing stockouts. This continuous flow of accurate information enhances inventory accuracy, operational efficiency, and customer satisfaction in retail environments.

Integration Challenges and Opportunities

Inventory management systems often face integration challenges with smart shelves due to disparate data formats and legacy technology incompatibility, which can hinder real-time stock accuracy and automated replenishment. Overcoming these challenges creates opportunities for seamless data synchronization, enhanced inventory visibility, and predictive analytics that optimize stock levels and reduce waste. Retailers investing in integrated solutions benefit from improved operational efficiency and customer satisfaction through precise inventory tracking and timely product availability.

Case Studies: Retailers Adopting Smart Shelves

Retailers adopting smart shelves report a 30% reduction in stockouts and a 25% increase in sales according to recent case studies from Walmart and Kroger. Smart shelves use IoT sensors and real-time data analytics to optimize inventory management, enhancing accuracy and operational efficiency. These technologies enable automated restocking alerts and dynamic pricing, driving improved customer satisfaction and higher profit margins.

The Future of Inventory Management in Retail

The future of inventory management in retail is increasingly driven by the integration of smart shelves powered by IoT sensors and real-time data analytics, enabling precise stock tracking and automatic replenishment. Smart shelves reduce human error and out-of-stock situations by providing continuous inventory visibility and customer interaction data. Retailers leveraging AI-driven inventory management systems experience improved supply chain efficiency, enhanced customer satisfaction, and optimized stock turnover rates.

Related Important Terms

RFID-Based Inventory Tracking

RFID-based inventory tracking revolutionizes retail inventory management by enabling real-time data capture and automatic stock updates, reducing human error and enhancing accuracy. Smart shelves equipped with RFID sensors streamline product identification and replenishment processes, optimizing stock levels and improving overall store efficiency.

Dynamic Shelf Replenishment

Dynamic Shelf Replenishment leverages smart shelves equipped with IoT sensors and real-time data analytics to optimize inventory management by automatically monitoring stock levels and triggering replenishment orders instantly. This technology minimizes stockouts and overstock situations, enhancing operational efficiency and improving the customer shopping experience in retail environments.

Real-Time Stock Visibility

Inventory management systems provide comprehensive tracking of stock levels across warehouses and stores, while smart shelves utilize IoT sensors to offer precise real-time stock visibility on the retail floor. Integrating smart shelves with inventory management enables automated restocking alerts and reduces stockouts by continuously monitoring product quantities at the shelf level.

Electronic Shelf Labels (ESL)

Electronic Shelf Labels (ESL) enhance inventory management by providing real-time pricing and stock updates, reducing manual errors and improving shelf accuracy in retail environments. Integration of ESL technology automates dynamic pricing and stock monitoring, leading to optimized inventory turnover and improved customer experience.

Shelf Sensor Networks

Shelf sensor networks enhance inventory management by providing real-time data on stock levels, product placement, and customer interactions, enabling retailers to optimize replenishment cycles and reduce out-of-stock incidents. These smart shelves leverage IoT technology and advanced analytics to improve accuracy in inventory tracking and streamline supply chain operations within retail environments.

Predictive Stock Analytics

Predictive stock analytics in inventory management leverages historical sales data and machine learning to forecast demand, optimize stock levels, and reduce overstock or stockouts. Smart shelves enhance this process by using IoT sensors and real-time data to automatically update inventory status and trigger replenishment alerts, ensuring continuous stock availability and improved retail efficiency.

Shrinkage Detection AI

Inventory management systems track stock levels and sales data to optimize replenishment, while smart shelves equipped with shrinkage detection AI use sensors and computer vision to identify theft or misplaced items in real-time. Shrinkage detection AI enhances loss prevention by analyzing shelf activity patterns and alerting staff immediately, reducing inventory discrepancies and improving overall retail security.

Planogram Compliance Automation

Inventory management systems enhance planogram compliance by tracking stock levels and product placement, reducing out-of-stock situations and ensuring optimal shelf organization. Smart shelves automate planogram adherence through real-time sensor data and AI-driven analytics, enabling dynamic adjustments and minimizing human error for improved retail efficiency.

Autonomous Shelf Scanning

Autonomous shelf scanning technology revolutionizes inventory management by using AI-powered cameras and sensors to monitor stock levels in real-time, reducing human errors and restocking delays. Integrating smart shelves enables retailers to optimize shelf space, improve product availability, and enhance overall supply chain efficiency.

Cloud-Connected Shelf Systems

Cloud-connected shelf systems revolutionize inventory management by providing real-time data on stock levels, reducing out-of-stock situations and enabling dynamic restocking. Integration of smart shelves with IoT sensors and cloud platforms enhances accuracy, optimizes supply chain workflows, and improves customer experience through timely product availability.

Inventory Management vs Smart Shelves Infographic

industrydif.com

industrydif.com