Planogram automation revolutionizes retail merchandising by using AI and data analytics to optimize shelf layouts, enhancing product visibility and sales. Traditional planograms rely on manual design and periodic updates, which can be time-consuming and prone to human error. Automated solutions enable real-time adjustments based on inventory levels, consumer behavior, and market trends, ensuring efficient space utilization and improved shopper experience.

Table of Comparison

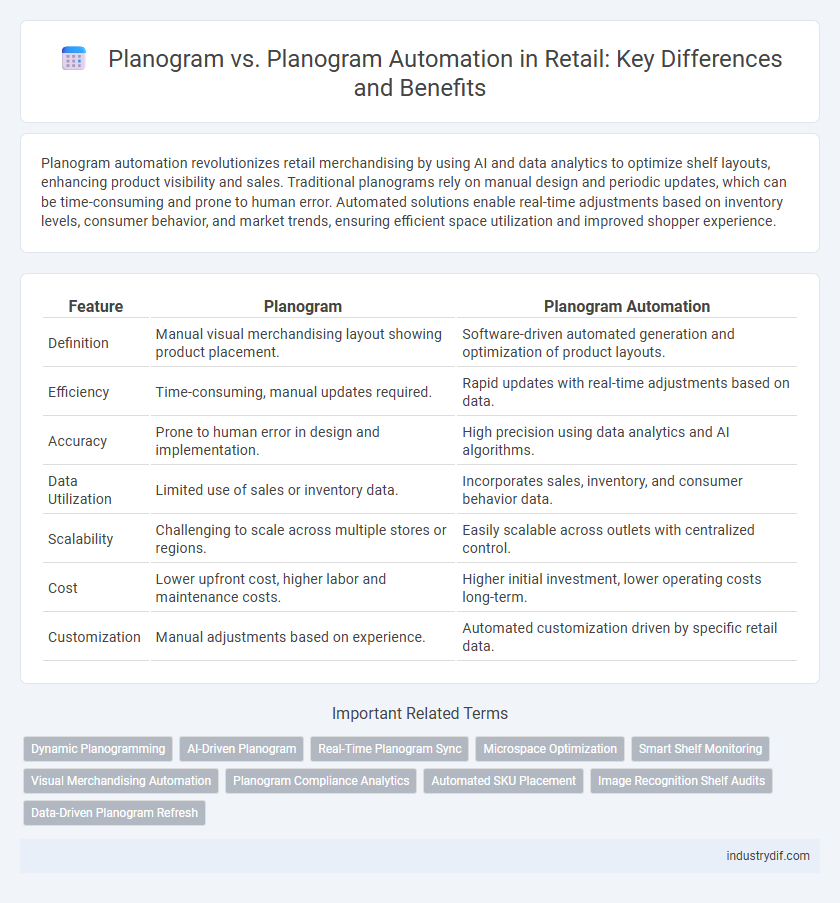

| Feature | Planogram | Planogram Automation |

|---|---|---|

| Definition | Manual visual merchandising layout showing product placement. | Software-driven automated generation and optimization of product layouts. |

| Efficiency | Time-consuming, manual updates required. | Rapid updates with real-time adjustments based on data. |

| Accuracy | Prone to human error in design and implementation. | High precision using data analytics and AI algorithms. |

| Data Utilization | Limited use of sales or inventory data. | Incorporates sales, inventory, and consumer behavior data. |

| Scalability | Challenging to scale across multiple stores or regions. | Easily scalable across outlets with centralized control. |

| Cost | Lower upfront cost, higher labor and maintenance costs. | Higher initial investment, lower operating costs long-term. |

| Customization | Manual adjustments based on experience. | Automated customization driven by specific retail data. |

Understanding Planogram: Definition and Purpose

A planogram is a detailed visual representation that outlines product placement on retail shelves, designed to maximize sales and improve customer experience by optimizing space and ensuring product visibility. Understanding planogram automation involves leveraging software to generate and adjust these layouts more efficiently, reducing manual errors and enabling real-time updates based on sales data and inventory levels. This automation enhances retail operations by streamlining planogram creation and ensuring consistent compliance across multiple store locations.

What is Planogram Automation? Key Concepts

Planogram automation leverages advanced software and data analytics to create, manage, and optimize retail shelf layouts with precision and efficiency. Key concepts include real-time inventory integration, automated compliance tracking, and AI-driven space optimization to enhance product visibility and maximize sales. This technology reduces manual labor, ensures consistency across multiple store locations, and adapts quickly to changing consumer trends and inventory levels.

Traditional Planogram Creation: Manual Methods

Traditional planogram creation relies heavily on manual methods, involving intensive human effort to arrange product placements based on visual merchandising principles and sales data analysis. This manual process is time-consuming, prone to errors, and often lacks the agility needed to respond to real-time consumer trends or inventory changes. Retailers face challenges in maintaining consistency and optimizing shelf space without advanced tools, highlighting limitations compared to planogram automation solutions.

Benefits of Manual Planogramming

Manual planogramming offers retailers precise control over product placement, allowing for tailored merchandising strategies that reflect unique store layouts and customer preferences. This hands-on approach enhances the ability to optimize shelf space effectively, leading to improved product visibility and increased sales. Retailers can swiftly adapt to local market trends and seasonal demands without relying on automated systems.

Limitations of Manual Planogram Processes

Manual planogram processes often suffer from time inefficiency and human error, leading to suboptimal shelf layouts and inconsistent product placement. Limited scalability restricts quick adjustments to inventory changes or seasonal promotions, impacting overall store performance. In contrast, planogram automation leverages data analytics and AI to streamline updates, enhance accuracy, and maximize retail space utilization.

How Planogram Automation Transforms Retail

Planogram automation revolutionizes retail by using AI-driven software to design and implement shelf layouts that optimize product placement and maximize sales. This technology analyzes real-time sales data, shopper behavior, and inventory levels to adjust planograms dynamically, enhancing inventory turnover and shopper experience. By replacing manual planogram creation, automation reduces labor costs and improves accuracy, enabling retailers to respond swiftly to market trends and consumer demands.

Advantages of Automated Planogram Solutions

Automated planogram solutions enhance retail efficiency by leveraging AI-powered analytics to optimize product placement based on real-time sales data and consumer behavior insights. These systems reduce human error and labor costs by automatically generating and updating shelf layouts, ensuring compliance with merchandising standards. Integration with inventory management software allows for dynamic adjustments to stock levels, improving shelf replenishment accuracy and maximizing sales potential.

Comparing Implementation: Manual vs Automated Planograms

Manual planogram implementation relies heavily on human labor, leading to slower shelf adjustments and increased potential for errors in product placement. Automated planograms use advanced software and data analytics to streamline shelf layout processes, improving accuracy and enabling real-time updates based on sales and inventory data. Retailers leveraging planogram automation benefit from enhanced operational efficiency and more effective product assortment that aligns with consumer behavior trends.

Data-Driven Merchandising and Planogram Automation

Planogram automation leverages data-driven merchandising by using advanced analytics and consumer insights to optimize product placement and inventory management effectively. Automated planogram tools enhance accuracy and speed in updating shelf layouts, ensuring real-time responsiveness to market trends and sales performance. This integration of data-driven strategies with automation drives higher sales, reduces stockouts, and improves overall retail store efficiency.

Choosing the Right Planogram Strategy for Your Retail Business

Planogram automation leverages advanced software and AI to design shelf layouts based on data-driven insights, increasing efficiency and accuracy compared to traditional manual planograms. Choosing the right planogram strategy involves evaluating store size, product assortment complexity, and real-time inventory data to maximize shelf space utilization and enhance customer experience. Retailers that integrate automated planograms often see improved sales performance, reduced labor costs, and faster adaptation to market trends.

Related Important Terms

Dynamic Planogramming

Dynamic planogramming leverages real-time sales data and consumer behavior analytics to continuously update shelf layouts, optimizing product placement for maximum sales impact. Planogram automation integrates AI-driven tools that streamline this process, reducing manual labor and enhancing responsiveness to market trends in retail environments.

AI-Driven Planogram

AI-driven planogram automation leverages advanced machine learning algorithms to optimize product placement, increasing shelf efficiency, boosting sales, and enhancing customer experience compared to traditional planogram methods. This technology analyzes real-time sales data, consumer behavior, and inventory levels to dynamically update layouts, ensuring retailers maximize profitability and adapt swiftly to market trends.

Real-Time Planogram Sync

Real-time planogram sync enhances retail accuracy by automatically updating product placements across multiple stores, minimizing discrepancies and ensuring compliance with merchandising standards. Planogram automation streamlines inventory management and shelf arrangement, reducing manual errors and accelerating promotional rollouts.

Microspace Optimization

Planogram automation enhances microspace optimization by using advanced algorithms to analyze product placement, increasing shelf efficiency and boosting sales per square foot. Automated systems provide dynamic adjustments based on real-time data, ensuring optimal inventory display and improved customer experience compared to traditional static planograms.

Smart Shelf Monitoring

Planogram automation leverages smart shelf monitoring technology to optimize product placement based on real-time inventory and shopper behavior data, significantly improving planogram compliance and sales performance. Integrating IoT sensors and AI analytics enables retailers to dynamically adjust displays, reduce out-of-stock incidents, and enhance customer experience compared to traditional static planograms.

Visual Merchandising Automation

Planogram automation leverages advanced software and AI to create precise, data-driven visual merchandising layouts, enhancing retail shelf space efficiency and customer experience. This automation reduces manual errors and enables dynamic planogram adjustments based on real-time sales data and inventory levels, outperforming traditional static planogram methods.

Planogram Compliance Analytics

Planogram compliance analytics leverages data-driven insights to measure how accurately store shelves match predefined product layouts, enhancing inventory management and visual merchandising effectiveness. Automated planogram tools improve compliance by using real-time shelf data and analytics to identify discrepancies faster than manual reviews, leading to optimized product placement and increased sales performance.

Automated SKU Placement

Automated SKU placement in planogram automation leverages AI algorithms to optimize product positioning based on consumer behavior, sales data, and shelf space utilization, enhancing planogram accuracy and efficiency. This technology reduces manual errors, accelerates planogram updates, and improves inventory management, ultimately boosting retail sales and customer satisfaction.

Image Recognition Shelf Audits

Planogram automation leverages image recognition shelf audits to enhance retail merchandising accuracy by instantly analyzing product placement and stock levels against prescribed layouts. This technology reduces human error and increases audit efficiency, enabling retailers to optimize shelf organization and improve inventory management in real time.

Data-Driven Planogram Refresh

Planogram automation leverages real-time sales data, customer behavior analytics, and inventory metrics to enable precise, data-driven planogram refreshes that enhance shelf space efficiency and optimize product placement. Manual planogram updates lack this dynamic capability, often resulting in suboptimal stock levels and missed sales opportunities.

Planogram vs Planogram Automation Infographic

industrydif.com

industrydif.com