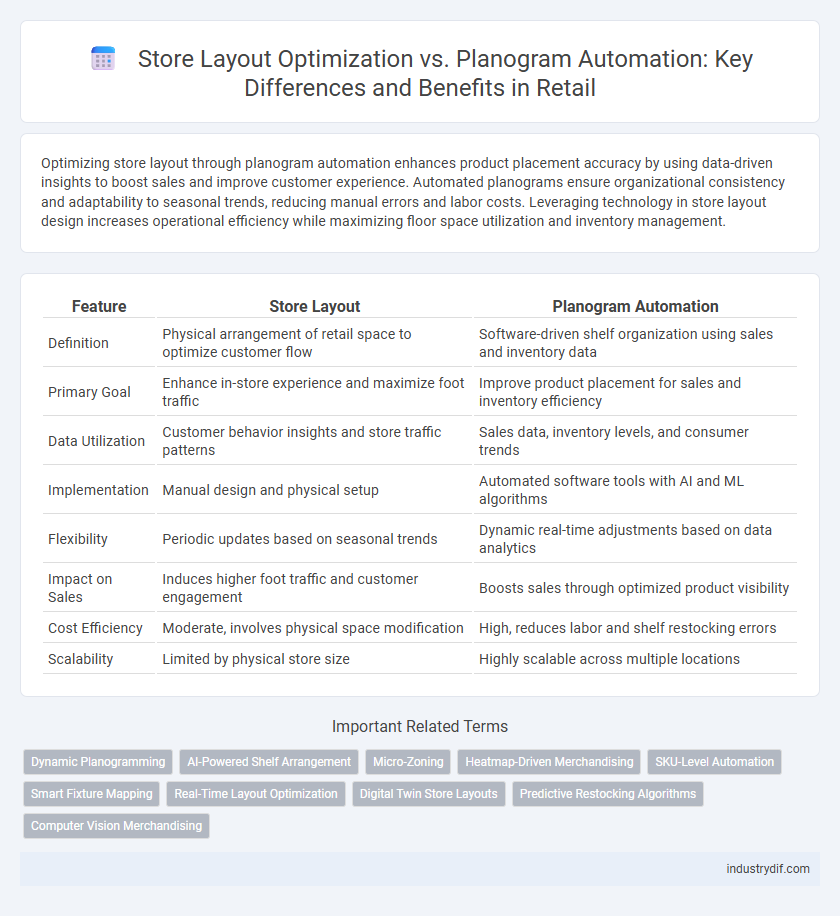

Optimizing store layout through planogram automation enhances product placement accuracy by using data-driven insights to boost sales and improve customer experience. Automated planograms ensure organizational consistency and adaptability to seasonal trends, reducing manual errors and labor costs. Leveraging technology in store layout design increases operational efficiency while maximizing floor space utilization and inventory management.

Table of Comparison

| Feature | Store Layout | Planogram Automation |

|---|---|---|

| Definition | Physical arrangement of retail space to optimize customer flow | Software-driven shelf organization using sales and inventory data |

| Primary Goal | Enhance in-store experience and maximize foot traffic | Improve product placement for sales and inventory efficiency |

| Data Utilization | Customer behavior insights and store traffic patterns | Sales data, inventory levels, and consumer trends |

| Implementation | Manual design and physical setup | Automated software tools with AI and ML algorithms |

| Flexibility | Periodic updates based on seasonal trends | Dynamic real-time adjustments based on data analytics |

| Impact on Sales | Induces higher foot traffic and customer engagement | Boosts sales through optimized product visibility |

| Cost Efficiency | Moderate, involves physical space modification | High, reduces labor and shelf restocking errors |

| Scalability | Limited by physical store size | Highly scalable across multiple locations |

Introduction to Store Layout and Planogram Automation

Store layout design strategically arranges physical retail space to maximize customer flow and product visibility, directly impacting sales and shopper experience. Planogram automation utilizes software to create precise visual merchandising plans, optimizing shelf space and inventory placement according to data-driven insights. Integrating automated planograms with store layouts enhances operational efficiency by aligning product presentation with consumer behavior and store performance metrics.

Understanding Traditional Store Layout Strategies

Traditional store layout strategies prioritize customer flow, product placement, and visual merchandising to enhance shopping experience and maximize sales. These layouts rely on intuitive design principles such as grid, racetrack, or free-form arrangements that guide consumers through specific pathways. Understanding these foundational strategies is essential before transitioning to planogram automation, which optimizes shelf space with data-driven precision.

What is Planogram Automation?

Planogram automation refers to the use of software and AI technologies to design and optimize product placement on retail shelves, ensuring maximum visibility and sales efficiency. Automated planograms analyze consumer behavior and inventory data to create precise layouts that align with merchandising strategies. This technology reduces manual errors and speeds up store layout adjustments, enhancing overall retail performance.

Key Differences Between Store Layout and Planogram Automation

Store layout focuses on the overall design and flow of a retail space to optimize customer experience and traffic patterns, while planogram automation specifically manages product placement on shelves to maximize sales and inventory efficiency. Store layout considers spatial arrangement, aisle width, and fixture placement, whereas planogram automation uses data-driven tools to precisely position products based on sales data and customer behavior. The key difference lies in scale and purpose: store layout addresses macro-level store design, and planogram automation targets micro-level product organization.

Benefits of Manual Store Layout

Manual store layout design allows retailers to leverage human insight and creativity, optimizing product placement based on local customer behavior and preferences. This approach facilitates flexible adjustments in response to seasonal trends or in-store promotions without reliance on automated algorithms. By directly controlling store layout, retailers can create unique shopping experiences that enhance customer engagement and drive sales.

Advantages of Planogram Automation Tools

Planogram automation tools enhance retail store efficiency by enabling precise product placement based on data analytics and customer behavior insights, leading to optimized shelf space and increased sales. These tools reduce manual errors and time spent on planogram creation, allowing retailers to quickly adapt to inventory changes and promotional strategies. Integration with real-time sales data ensures that planograms remain dynamic and responsive to market trends, improving inventory turnover and customer satisfaction.

Challenges in Store Layout Optimization

Store layout optimization faces challenges such as accommodating diverse product categories, maximizing customer flow, and balancing aesthetic appeal with functional space utilization. Planogram automation must address data accuracy, real-time inventory changes, and integration with existing retail management systems to ensure effective shelf placement. Navigating these complexities is essential for enhancing shopper experience and driving sales performance.

Integrating Planogram Automation with Existing Retail Operations

Integrating planogram automation with existing retail operations streamlines shelf management and ensures real-time compliance with merchandising standards. Advanced software solutions enable seamless synchronization between planogram data and inventory systems, improving product placement accuracy and reducing out-of-stock incidents. Retailers benefit from increased operational efficiency, enhanced customer experience, and data-driven insights that optimize store layout strategies.

Impact on Sales and Customer Experience

Store layout optimization strategically enhances customer flow and product visibility, directly boosting sales by encouraging spontaneous purchases. Planogram automation ensures consistent product placement, reducing human errors and enabling rapid adjustments based on real-time sales data. Together, these technologies improve customer experience by creating intuitive shopping environments and maximizing shelf efficiency, driving higher engagement and revenue.

Future Trends in Store Layout and Planogram Automation

Future trends in store layout and planogram automation emphasize the integration of AI-driven analytics and real-time shopper behavior data to optimize product placement and inventory management. Retailers are increasingly adopting IoT sensors and advanced machine learning models to personalize store environments, enhancing customer engagement and driving sales. Automation tools will also leverage augmented reality (AR) to visualize planogram changes dynamically, improving accuracy and reducing labor costs.

Related Important Terms

Dynamic Planogramming

Dynamic planogramming leverages real-time sales data and inventory levels to automatically adjust store layouts, optimizing product placement for improved shopper engagement and increased sales. Integrating dynamic planogram automation with retail store layouts reduces manual intervention, enhances shelf space efficiency, and ensures adaptive merchandising aligned with consumer behavior trends.

AI-Powered Shelf Arrangement

AI-powered shelf arrangement enhances retail efficiency by automating store layouts and planograms, optimizing product placement based on consumer behavior and sales data. This technology increases shelf space utilization and improves customer experience by dynamically adjusting displays to maximize sales and inventory turnover.

Micro-Zoning

Micro-zoning in retail enhances store layout efficiency by using planogram automation to precisely allocate product placements and optimize space utilization for targeted shopper behavior. Automated planogram systems analyze sales data and customer flow patterns to dynamically adjust micro-zones, increasing product visibility and driving sales.

Heatmap-Driven Merchandising

Heatmap-driven merchandising leverages customer movement and engagement data to optimize store layouts and planogram automation, improving product placement based on real-time shopper behavior patterns. This technology enhances retail performance by increasing dwell times and boosting sales through strategic allocation of high-traffic areas to high-margin products.

SKU-Level Automation

SKU-level automation in store layouts enhances planogram accuracy by dynamically adjusting product placements based on real-time inventory data and consumer behavior analytics. This precision-driven approach maximizes shelf efficiency, reduces stockouts, and boosts overall sales performance in retail environments.

Smart Fixture Mapping

Smart fixture mapping enhances store layout efficiency by automating planogram creation, ensuring optimal product placement based on real-time sales and shopper behavior data. This technology streamlines inventory management and boosts sales by dynamically adapting displays to maximize customer engagement and in-store navigation.

Real-Time Layout Optimization

Real-time layout optimization leverages planogram automation to dynamically adjust store layouts based on current sales data, customer traffic patterns, and inventory levels, enhancing product visibility and maximizing space efficiency. This proactive approach reduces manual adjustments, improves shopper experience, and drives higher conversion rates by aligning shelf placement with evolving consumer behavior.

Digital Twin Store Layouts

Digital Twin Store Layouts enable retailers to simulate and optimize store configurations virtually, enhancing planogram automation accuracy by predicting customer flow and product placement effectiveness. Integrating digital twins with planogram automation streamlines inventory management and increases sales by aligning merchandising strategies with real-time shopper behavior data.

Predictive Restocking Algorithms

Predictive restocking algorithms leverage data analytics and machine learning within store layout and planogram automation to optimize product placement and inventory levels, reducing stockouts and overstock situations. These algorithms analyze customer purchase patterns and sales trends to forecast demand accurately, ensuring shelves are replenished timely and enhancing overall retail efficiency.

Computer Vision Merchandising

Computer vision merchandising leverages advanced image recognition technology to automate planogram compliance, enabling retailers to optimize store layout with real-time data analytics and enhance product placement accuracy. This automation reduces manual shelf audits, increases operational efficiency, and drives higher sales through precise inventory management and better visual merchandising strategies.

Store Layout vs Planogram Automation Infographic

industrydif.com

industrydif.com