Safety Data Sheets (SDS) provide essential chemical hazard information in a static format that is crucial for pet safety but often lacks real-time updates and interactive features. Digital Safety Twins offer a dynamic, interactive model that simulates and monitors pet environments, allowing for proactive risk management and immediate response to potential hazards. Integrating Digital Safety Twins with SDS data enhances comprehensive safety strategies by combining detailed chemical information with continuous environmental monitoring.

Table of Comparison

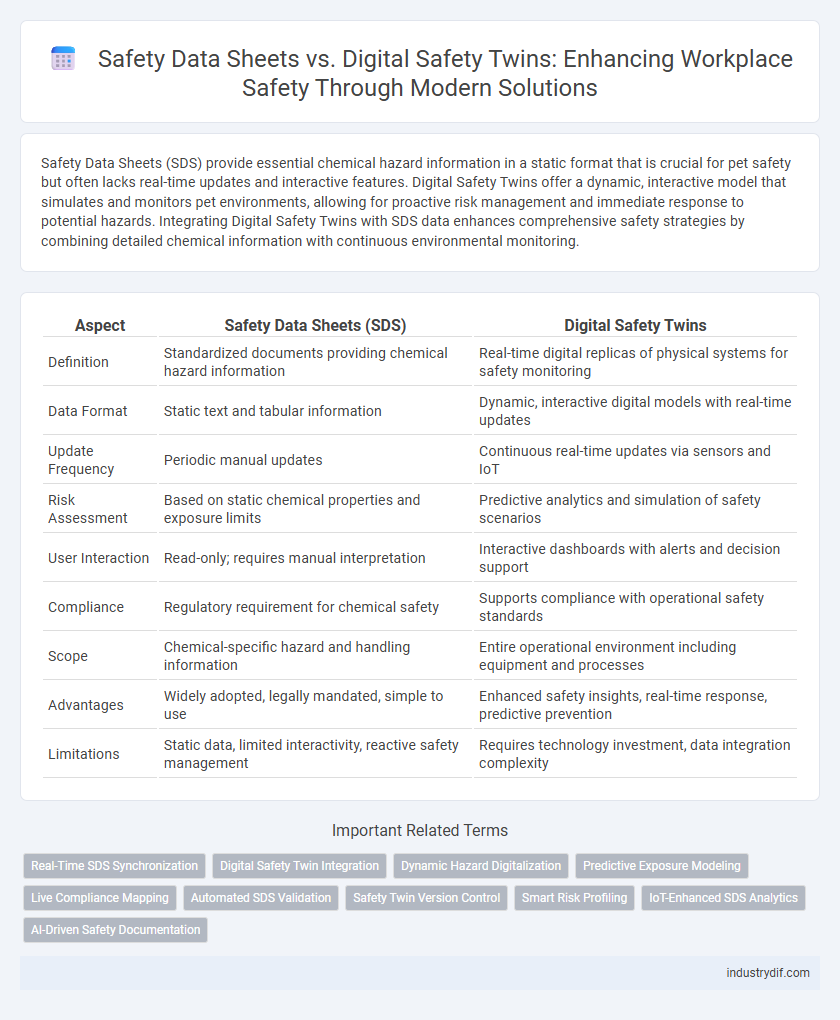

| Aspect | Safety Data Sheets (SDS) | Digital Safety Twins |

|---|---|---|

| Definition | Standardized documents providing chemical hazard information | Real-time digital replicas of physical systems for safety monitoring |

| Data Format | Static text and tabular information | Dynamic, interactive digital models with real-time updates |

| Update Frequency | Periodic manual updates | Continuous real-time updates via sensors and IoT |

| Risk Assessment | Based on static chemical properties and exposure limits | Predictive analytics and simulation of safety scenarios |

| User Interaction | Read-only; requires manual interpretation | Interactive dashboards with alerts and decision support |

| Compliance | Regulatory requirement for chemical safety | Supports compliance with operational safety standards |

| Scope | Chemical-specific hazard and handling information | Entire operational environment including equipment and processes |

| Advantages | Widely adopted, legally mandated, simple to use | Enhanced safety insights, real-time response, predictive prevention |

| Limitations | Static data, limited interactivity, reactive safety management | Requires technology investment, data integration complexity |

Understanding Safety Data Sheets (SDS): Definition and Purpose

Safety Data Sheets (SDS) provide detailed information on the properties, hazards, and safe handling of chemical substances, serving as a critical resource for workplace safety and regulatory compliance. They include essential data such as chemical composition, exposure limits, first-aid measures, and storage guidelines to prevent accidents and health risks. Understanding SDS is fundamental for employers and employees to implement effective safety protocols and mitigate potential hazards in industrial environments.

Introduction to Digital Safety Twins in Modern Industry

Digital Safety Twins revolutionize modern industry by creating real-time, virtual replicas of physical assets and environments, enabling proactive hazard identification and risk management. Unlike traditional Safety Data Sheets (SDS), which provide static chemical and material information, Digital Safety Twins integrate sensor data, operational parameters, and predictive analytics for dynamic safety monitoring. This advanced approach enhances incident prevention, regulatory compliance, and workforce protection through continuous, data-driven insights.

Key Differences Between SDS and Digital Safety Twins

Safety Data Sheets (SDS) provide standardized, static information about hazardous chemicals, detailing properties, handling, and emergency measures. Digital Safety Twins offer dynamic, real-time digital models of physical assets, enabling continuous monitoring, risk assessment, and predictive safety management. Unlike SDS, Digital Safety Twins integrate sensor data and advanced analytics to enhance proactive safety strategies and operational decision-making.

Regulatory Compliance: SDS vs Digital Safety Twins

Safety Data Sheets (SDS) provide essential regulatory compliance by detailing hazardous chemical properties and safe handling instructions as mandated by OSHA and GHS standards. Digital Safety Twins enhance compliance by offering real-time tracking, dynamic updates, and integration of SDS information within digital asset management systems. Combining SDS with Digital Safety Twins ensures accurate regulatory adherence, reduces human error, and supports proactive risk management.

Data Accessibility and User Experience

Safety Data Sheets (SDS) provide essential chemical safety information but often suffer from limited accessibility and static formats, hindering quick data retrieval in emergencies. Digital Safety Twins enhance user experience by offering real-time, interactive access to comprehensive safety data through cloud platforms and mobile integration, facilitating immediate decision-making. These dynamic models improve data accuracy and accessibility, enabling safer workplace environments and more efficient risk management.

Real-Time Updates and Information Accuracy

Safety Data Sheets (SDS) provide essential chemical hazard information but often lack real-time updates, potentially leading to outdated safety protocols. Digital Safety Twins integrate real-time data from sensors and operational systems, ensuring accurate and dynamic hazard information to enhance workplace safety. This continuous updating capability improves risk assessment accuracy and responsiveness to changing conditions.

Integration with Occupational Health and Safety Systems

Safety Data Sheets (SDS) provide essential chemical hazard information but often lack real-time integration with Occupational Health and Safety (OHS) systems. Digital Safety Twins enhance workplace safety by creating dynamic, virtual replicas of physical environments that integrate live data from OHS platforms, enabling proactive hazard detection and response. This seamless integration improves compliance tracking, risk assessments, and emergency preparedness, advancing overall occupational safety management.

Risk Assessment Capabilities Compared

Safety Data Sheets (SDS) provide static chemical hazard information essential for compliance but lack dynamic risk assessment capabilities. Digital Safety Twins offer real-time monitoring and simulation of hazardous scenarios, enabling proactive risk management and predictive analytics. Integrating Digital Safety Twins enhances risk assessment accuracy by continuously updating safety data and modeling potential exposure impacts.

Challenges and Limitations of SDS and Digital Safety Twins

Safety Data Sheets (SDS) often face challenges such as static information that may not reflect real-time hazards, limited accessibility in emergency situations, and difficulties in comprehension due to technical jargon. Digital Safety Twins encounter limitations including high implementation costs, the need for continuous data integration, and potential cybersecurity vulnerabilities exposing sensitive safety information. Both systems must overcome issues related to data accuracy, timely updates, and user-friendly interfaces to enhance overall workplace safety management.

Future Trends: Evolving Safety Documentation Technologies

Safety Data Sheets (SDS) have long been the standard for hazard communication, but Digital Safety Twins are transforming safety documentation by providing real-time, interactive simulations of chemical and workplace hazards. Future trends indicate a shift toward integrating artificial intelligence and IoT sensors with Digital Safety Twins, enabling dynamic risk assessments and predictive analytics to enhance worker safety. Companies leveraging cloud-based platforms and augmented reality will lead the evolution of safety management by offering more accurate, accessible, and up-to-date hazard information.

Related Important Terms

Real-Time SDS Synchronization

Real-time SDS synchronization enhances workplace safety by providing instant access to the most current Safety Data Sheets, reducing the risk of handling outdated chemical information. Digital Safety Twins integrate real-time updates and hazard monitoring, creating dynamic, accurate safety profiles that improve incident response and regulatory compliance.

Digital Safety Twin Integration

Digital Safety Twin integration revolutionizes traditional Safety Data Sheets by providing real-time, dynamic interaction with hazardous material data, enhancing workplace safety through continuous monitoring and predictive analytics. This advanced system enables precise risk management and rapid response by simulating environmental conditions and operational scenarios, surpassing static SDS limitations.

Dynamic Hazard Digitalization

Safety Data Sheets provide static chemical hazard information, while Digital Safety Twins enable dynamic hazard digitalization by continuously updating real-time risk data through sensor integration and predictive analytics. This dynamic approach enhances workplace safety by allowing proactive hazard identification, immediate response to changing conditions, and improved compliance management.

Predictive Exposure Modeling

Safety Data Sheets provide static chemical hazard information, while Digital Safety Twins leverage real-time data and predictive exposure modeling to simulate and forecast hazardous exposure scenarios. Predictive exposure modeling within Digital Safety Twins enhances proactive risk management by dynamically assessing environmental conditions and worker interactions.

Live Compliance Mapping

Safety Data Sheets (SDS) provide static, regulatory information crucial for hazard communication, whereas Digital Safety Twins enable dynamic, real-time compliance mapping by integrating live sensor data and environmental changes. This live compliance mapping supports proactive risk management and immediate response to safety deviations, enhancing workplace safety beyond traditional SDS capabilities.

Automated SDS Validation

Automated SDS validation through Digital Safety Twins enhances accuracy and compliance by continuously monitoring chemical safety data against real-time operational conditions, reducing human error inherent in manual Safety Data Sheets management. This integration streamlines regulatory adherence and accelerates hazard communication, promoting a proactive safety culture in industrial environments.

Safety Twin Version Control

Safety Data Sheets provide static safety information while Digital Safety Twins enable dynamic, real-time updates and version control for enhanced accuracy. Digital Safety Twins streamline compliance by ensuring every safety update is instantly reflected and traceable across all platforms.

Smart Risk Profiling

Safety Data Sheets provide standardized chemical hazard information while Digital Safety Twins create dynamic, real-time risk profiles by integrating sensor data and environmental variables. Smart Risk Profiling leverages Digital Safety Twins to predict hazards more accurately, enhance decision-making, and enable proactive risk mitigation beyond static Safety Data Sheets.

IoT-Enhanced SDS Analytics

Safety Data Sheets (SDS) provide static chemical hazard information, while Digital Safety Twins leverage IoT sensors to offer real-time monitoring and dynamic risk analytics. IoT-enhanced SDS analytics enable predictive safety management by integrating live data streams with traditional hazard documentation, significantly improving workplace hazard detection and response.

AI-Driven Safety Documentation

Safety Data Sheets (SDS) provide standardized chemical hazard information essential for regulatory compliance and workplace safety, but AI-driven Digital Safety Twins enhance this by offering real-time, interactive simulations and predictive analytics for dynamic risk assessment. Leveraging machine learning algorithms, Digital Safety Twins continuously update safety protocols and hazard scenarios, enabling proactive decision-making and reducing incidents more effectively than static SDS documents.

Safety Data Sheets vs Digital Safety Twins Infographic

industrydif.com

industrydif.com