Lockout Tagout (LOTO) is a traditional safety procedure that uses physical locks and tags to ensure machinery remains de-energized during maintenance, preventing accidental startup and enhancing worker safety. In contrast, digital lockout systems leverage technology to monitor and control machine locks remotely, offering real-time status updates, reducing human error, and streamlining compliance documentation. Implementing a digital lockout system increases operational efficiency while maintaining rigorous safety standards in industrial environments.

Table of Comparison

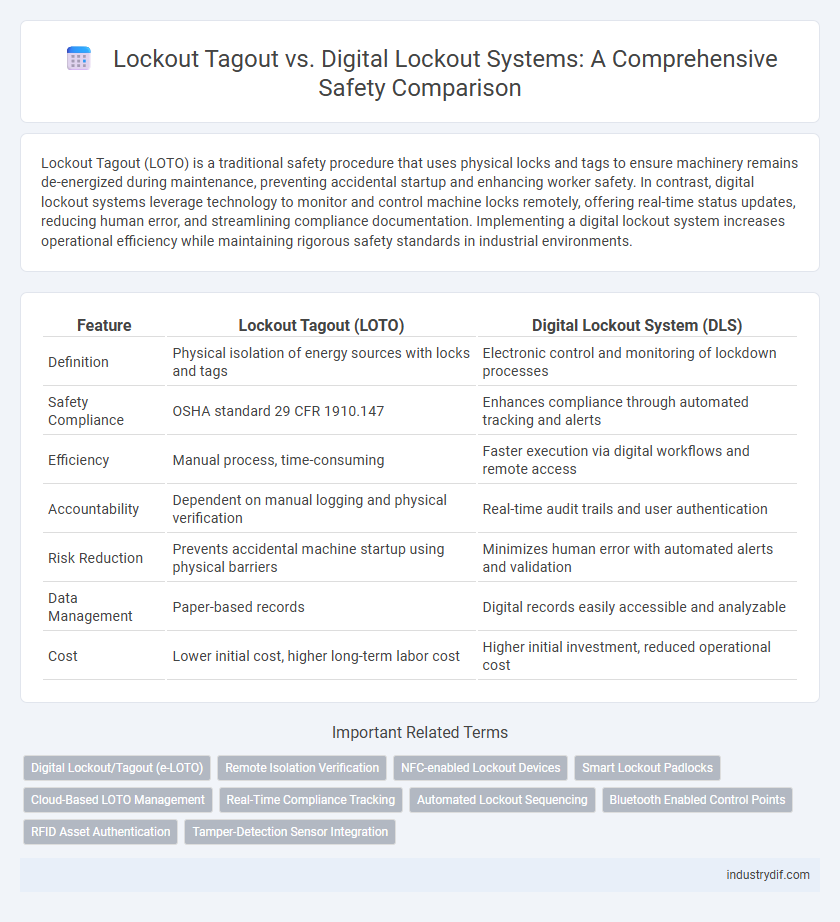

| Feature | Lockout Tagout (LOTO) | Digital Lockout System (DLS) |

|---|---|---|

| Definition | Physical isolation of energy sources with locks and tags | Electronic control and monitoring of lockdown processes |

| Safety Compliance | OSHA standard 29 CFR 1910.147 | Enhances compliance through automated tracking and alerts |

| Efficiency | Manual process, time-consuming | Faster execution via digital workflows and remote access |

| Accountability | Dependent on manual logging and physical verification | Real-time audit trails and user authentication |

| Risk Reduction | Prevents accidental machine startup using physical barriers | Minimizes human error with automated alerts and validation |

| Data Management | Paper-based records | Digital records easily accessible and analyzable |

| Cost | Lower initial cost, higher long-term labor cost | Higher initial investment, reduced operational cost |

Introduction to Lockout Tagout (LOTO)

Lockout Tagout (LOTO) is a critical safety procedure used to ensure that machinery and electrical systems are properly shut off and unable to be started up during maintenance or repair work. This process involves placing physical locks and tags on energy-isolating devices to prevent accidental energization, significantly reducing the risk of workplace injuries. Traditional LOTO systems rely on mechanical locks and visual warnings, whereas digital lockout systems integrate electronic controls for enhanced monitoring and audit compliance.

Traditional Lockout Tagout: Key Principles

Traditional Lockout Tagout (LOTO) systems emphasize isolating hazardous energy sources through physical locks and tags to prevent accidental machine start-up during maintenance. Key principles include verifying energy isolation, applying durable lockout devices, and ensuring authorized personnel control the keys. This method relies heavily on strict procedural compliance and clear communication to maintain workplace safety and prevent energy-related injuries.

Digital Lockout Systems: An Overview

Digital lockout systems enhance workplace safety by providing real-time monitoring and control over hazardous equipment, reducing human error risk during maintenance. These systems integrate with existing machinery through IoT sensors and software platforms, allowing automated lockout procedures and remote access management. Advanced data analytics and audit trails enable compliance with OSHA lockout tagout standards, improving overall operational efficiency and safety protocols.

Compliance and Regulatory Standards Comparison

Lockout Tagout (LOTO) procedures comply with OSHA 29 CFR 1910.147, ensuring worker safety by physically isolating hazardous energy sources during maintenance. Digital Lockout Systems enhance compliance by providing automated audit trails and real-time status monitoring, aligning with ISO 45001 occupational health and safety management standards. Employers adopting digital systems benefit from increased regulatory adherence through improved accuracy, record-keeping, and streamlined inspection processes.

Safety Performance: Manual vs Digital Approaches

Digital lockout systems enhance safety performance by reducing human error and ensuring real-time verification of energy isolation, unlike manual lockout tagout procedures that rely heavily on individual compliance and physical tags. Digital systems enable automated notifications, audit trails, and remote monitoring, significantly lowering the risk of accidental equipment startup and improving workforce protection. Studies show facilities implementing digital lockout solutions experience fewer lockout-related incidents and faster incident response times compared to traditional manual approaches.

Efficiency and Downtime Reduction

Digital Lockout Systems significantly enhance efficiency by automating lockout tagout procedures, reducing human error and ensuring real-time updates on equipment status. These systems minimize downtime through faster identification and resolution of safety hazards, enabling quicker equipment restarts. Compared to traditional Lockout Tagout, digital solutions streamline compliance tracking and improve communication across maintenance teams, leading to safer and more efficient operations.

Risk Mitigation and Incident Prevention

Lockout Tagout (LOTO) procedures effectively reduce machinery-related hazards by physically isolating energy sources, but are prone to human error and inconsistent compliance. Digital Lockout Systems enhance risk mitigation by automating lockout verification, providing real-time monitoring, and maintaining detailed audit trails that improve incident prevention accuracy. Integrating digital solutions decreases unauthorized equipment access and significantly lowers the potential for workplace accidents compared to traditional LOTO methods.

Implementation Challenges and Solutions

Lockout Tagout (LOTO) implementation faces challenges such as human error, manual documentation, and limited real-time monitoring, which can lead to non-compliance and safety risks. Digital Lockout Systems address these issues through automated workflows, electronic lock controls, and real-time tracking, significantly enhancing compliance and safety assurance. Overcoming obstacles in digital adoption involves user training, integration with existing safety protocols, and investment in compatible technology infrastructure.

Cost Analysis: Short-Term and Long-Term Investment

Lockout Tagout systems typically require lower initial investment with physical locks and tags but can incur higher long-term costs due to labor-intensive procedures and human error risks. Digital Lockout Systems demand a higher upfront cost for technology implementation but reduce ongoing expenses by improving efficiency, reducing downtime, and enhancing compliance tracking. Evaluating cost-effectiveness involves comparing immediate equipment and training expenses against future savings from minimized accidents and streamlined safety management.

Future Trends in Lockout Technology

Digital lockout systems represent the future of lockout technology, integrating IoT connectivity and real-time monitoring to enhance workplace safety. These advanced systems enable remote control, automatic notifications, and data analytics to prevent unauthorized equipment energization and reduce human error. As industries adopt Industry 4.0 standards, the shift from traditional lockout tagout methods to smart digital solutions will drive improved compliance and operational efficiency.

Related Important Terms

Digital Lockout/Tagout (e-LOTO)

Digital Lockout/Tagout (e-LOTO) systems enhance workplace safety by providing real-time monitoring, automated compliance tracking, and remote management of lockout procedures, significantly reducing human error compared to traditional lockout tagout methods. These systems leverage IoT technology and cloud-based platforms to ensure precise control over hazardous energy isolation, improving auditability and operational efficiency in industrial environments.

Remote Isolation Verification

Remote isolation verification in digital lockout systems enhances safety by allowing real-time confirmation of equipment status without physical presence, reducing the risk of human error and exposure to hazards. Unlike traditional lockout tagout methods, digital systems utilize IoT sensors and secure communication protocols to provide accurate, instant status updates and audit trails, improving compliance and operational efficiency.

NFC-enabled Lockout Devices

NFC-enabled lockout devices enhance traditional Lockout Tagout procedures by allowing real-time digital verification and monitoring of equipment isolation, significantly reducing human error and improving compliance. Digital lockout systems integrated with NFC technology streamline access control and provide detailed audit trails, elevating workplace safety standards.

Smart Lockout Padlocks

Smart Lockout Padlocks enhance traditional Lockout Tagout safety protocols by integrating digital access control, real-time monitoring, and audit trail capabilities that prevent unauthorized equipment operation and reduce human error. These advanced padlocks streamline compliance with OSHA standards and improve workplace safety by offering remote management and data-driven insights.

Cloud-Based LOTO Management

Cloud-based Lockout Tagout (LOTO) management systems enhance safety by providing real-time monitoring, centralized data storage, and remote access to LOTO protocols, reducing human error and improving compliance. Digital Lockout Systems integrate IoT devices to automate lockout processes, streamline audit trails, and enable immediate response to safety breaches, surpassing traditional manual LOTO methods in efficiency and accountability.

Real-Time Compliance Tracking

Digital lockout systems enhance safety by providing real-time compliance tracking, ensuring immediate identification of unauthorized access and timely updates on lockout status. Unlike traditional lockout tagout procedures, these advanced systems utilize IoT technology to monitor and document every lockout event, reducing human error and improving regulatory adherence.

Automated Lockout Sequencing

Automated Lockout Sequencing in Digital Lockout Systems significantly enhances safety by reducing human error and ensuring precise control over energy isolation points compared to traditional Lockout Tagout procedures. These systems streamline compliance with OSHA standards, improve audit tracking, and provide real-time monitoring for hazardous energy control.

Bluetooth Enabled Control Points

Bluetooth-enabled control points in digital lockout systems enhance safety by providing real-time monitoring and remote management of lockout/tagout procedures, significantly reducing human error and unauthorized access. Unlike traditional lockout tagout methods, these digital systems enable instantaneous updates and audit trails, improving compliance and operational efficiency.

RFID Asset Authentication

RFID asset authentication in digital lockout systems enhances safety by providing precise real-time tracking and verification of locked-out equipment, significantly reducing human error compared to traditional lockout tagout methods. This technology ensures secure access control, instant audit trails, and improved compliance with OSHA lockout/tagout standards, elevating overall workplace safety.

Tamper-Detection Sensor Integration

Lockout Tagout procedures rely on physical locks and tags to ensure equipment safety during maintenance, while Digital Lockout Systems incorporate tamper-detection sensors that provide real-time alerts for unauthorized access attempts, enhancing compliance and reducing downtime. Integration of advanced tamper-detection sensors in digital systems improves safety by automatically logging incidents and enabling rapid response to potential hazards.

Lockout Tagout vs Digital Lockout System Infographic

industrydif.com

industrydif.com