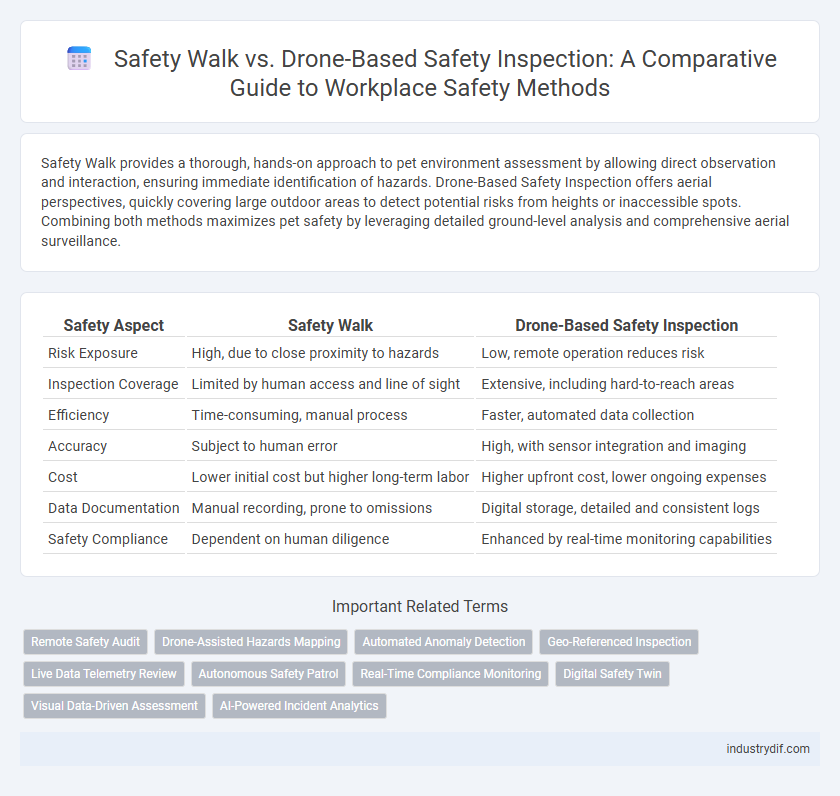

Safety Walk provides a thorough, hands-on approach to pet environment assessment by allowing direct observation and interaction, ensuring immediate identification of hazards. Drone-Based Safety Inspection offers aerial perspectives, quickly covering large outdoor areas to detect potential risks from heights or inaccessible spots. Combining both methods maximizes pet safety by leveraging detailed ground-level analysis and comprehensive aerial surveillance.

Table of Comparison

| Safety Aspect | Safety Walk | Drone-Based Safety Inspection |

|---|---|---|

| Risk Exposure | High, due to close proximity to hazards | Low, remote operation reduces risk |

| Inspection Coverage | Limited by human access and line of sight | Extensive, including hard-to-reach areas |

| Efficiency | Time-consuming, manual process | Faster, automated data collection |

| Accuracy | Subject to human error | High, with sensor integration and imaging |

| Cost | Lower initial cost but higher long-term labor | Higher upfront cost, lower ongoing expenses |

| Data Documentation | Manual recording, prone to omissions | Digital storage, detailed and consistent logs |

| Safety Compliance | Dependent on human diligence | Enhanced by real-time monitoring capabilities |

Introduction to Safety Walks and Drone-Based Safety Inspections

Safety walks involve manual, on-site inspections where trained personnel identify hazards by visually assessing work environments, ensuring compliance with safety standards. Drone-based safety inspections use unmanned aerial vehicles equipped with cameras and sensors to remotely inspect hard-to-reach or hazardous areas, providing real-time data and reducing risk to workers. Both methods enhance workplace safety protocols, with drones offering increased efficiency and access to elevated or confined spaces.

Key Differences Between Safety Walks and Drone Inspections

Safety walks involve on-foot inspections by personnel to identify hazards, ensuring real-time, tactile assessments of equipment and environments. Drone-based safety inspections utilize unmanned aerial vehicles equipped with cameras and sensors to access hard-to-reach or hazardous areas, enabling detailed aerial views and data collection without exposing workers to risk. Key differences include physical presence and direct interaction in safety walks versus remote, technology-driven data acquisition in drone inspections, impacting efficiency, coverage, and worker safety.

Benefits of Traditional Safety Walks in Industrial Settings

Traditional safety walks in industrial settings provide direct human observation, enabling inspectors to identify subtle hazards and behavioral risks that drones may overlook. These walks foster real-time communication and immediate feedback with workers, enhancing safety culture and compliance. Furthermore, the tactile presence during safety walks allows for quick resolution of issues, ensuring thorough and context-aware hazard mitigation.

Advantages of Drone-Based Safety Inspections

Drone-based safety inspections offer superior access to hard-to-reach or hazardous areas, significantly reducing risk to personnel and increasing operational efficiency. Equipped with high-resolution cameras and sensors, drones provide real-time data and comprehensive visual documentation, enhancing accuracy and enabling early detection of potential safety hazards. Furthermore, drones minimize inspection time and costs compared to traditional safety walks, making them a strategic choice for modern workplace safety management.

Limitations and Challenges: Safety Walks vs Drone Inspections

Safety Walks often face limitations such as human error, time constraints, and restricted access to hazardous or hard-to-reach areas, which can compromise thorough hazard identification. Drone-Based Safety Inspections overcome many access challenges and provide real-time data collection but are hindered by regulatory restrictions, battery life limitations, and the need for trained operators. Both methods require careful integration to address safety gaps, as Safety Walks provide essential human judgment while drones offer enhanced surveillance capabilities.

Technology Integration in Workplace Safety Monitoring

Drone-based safety inspections leverage advanced imaging technologies, such as thermal cameras and high-resolution sensors, to provide comprehensive workplace hazard detection that exceeds traditional safety walk capabilities. Integrating drones into safety monitoring enhances real-time data collection and enables remote access to hard-to-reach or hazardous areas, significantly improving response times and accuracy. This technological shift reduces human exposure to risks while optimizing safety protocols through detailed, data-driven insights.

Compliance and Regulatory Considerations

Safety walks offer hands-on, immediate compliance verification aligned with OSHA and ANSI standards, ensuring real-time identification of workplace hazards. Drone-based safety inspections provide extensive aerial access for comprehensive regulatory audits, adhering to FAA regulations and enhancing documentation accuracy for OSHA compliance. Both methods require strict adherence to data privacy laws and industry-specific safety regulations to maintain legal and operational standards.

Cost-Effectiveness: Manual vs Drone-Driven Safety Checks

Manual safety walks typically involve higher labor costs and extended inspection times compared to drone-based safety inspections, which significantly reduce human resource expenses through automation. Drone-driven safety checks offer rapid data collection and access to hard-to-reach or hazardous areas, minimizing downtime and operational disruptions. The initial investment in drone technology is offset by long-term savings from increased efficiency, enhanced data accuracy, and reduced risk exposure.

Case Studies: Real-World Applications of Both Methods

Case studies reveal that traditional safety walks provide hands-on hazard identification, allowing employees to engage directly with the environment, which improves immediate corrective actions. Drone-based safety inspections offer comprehensive aerial surveillance and access to hard-to-reach areas, significantly enhancing risk assessment in construction sites and industrial plants. Combining both methods maximizes safety outcomes by leveraging human insight and drone technology for thorough hazard detection and prevention.

Future Trends in Industrial Safety Inspections

Drone-based safety inspections are rapidly transforming industrial safety by enabling comprehensive, real-time data collection in hazardous environments, which traditional safety walks often miss. Future trends emphasize integrating AI-powered drones with advanced sensors to automate risk detection and analysis, enhancing accuracy and reducing human exposure to danger. This shift toward remote, technology-driven inspections promises improved safety protocols and operational efficiency across industries such as oil and gas, manufacturing, and construction.

Related Important Terms

Remote Safety Audit

Remote safety audits using drone-based safety inspections provide comprehensive visual data for hazard identification in hard-to-reach areas, significantly reducing the risk to personnel compared to traditional safety walks. These drone inspections enhance real-time monitoring capabilities and improve compliance tracking by capturing high-resolution images and videos accessible from centralized safety management systems.

Drone-Assisted Hazards Mapping

Drone-assisted hazards mapping enhances workplace safety by providing real-time aerial data that identifies potential risks more efficiently than traditional safety walks. This technology enables precise, comprehensive inspections of hard-to-reach areas, reducing human exposure to dangerous environments while improving hazard detection accuracy.

Automated Anomaly Detection

Automated anomaly detection in drone-based safety inspections leverages AI-driven image analysis to identify hazards faster and more accurately than traditional safety walks. This technology reduces human error by continuously monitoring large areas and promptly flagging irregularities that may be missed during manual inspections.

Geo-Referenced Inspection

Geo-referenced inspections using drones provide precise location data for hazard identification, enabling real-time mapping and documentation of safety risks across expansive or hard-to-access sites. This contrasts with traditional safety walks, which rely on manual observations and lack the spatial accuracy and efficiency offered by drone technology for comprehensive safety monitoring.

Live Data Telemetry Review

Safety Walks provide real-time, on-site hazard identification through direct human observation, enabling immediate corrective actions based on live environmental cues. Drone-Based Safety Inspections enhance this process by delivering live data telemetry, including high-resolution video feeds and sensor measurements, allowing remote teams to review and analyze safety conditions instantly, improving accuracy and response times.

Autonomous Safety Patrol

Autonomous safety patrols using drones provide continuous, real-time monitoring capabilities that surpass traditional safety walks in identifying hazards and ensuring compliance across complex industrial environments. These drone-based inspections enhance safety management by reducing human error, improving data accuracy, and enabling rapid response to potential risks.

Real-Time Compliance Monitoring

Real-time compliance monitoring through drone-based safety inspection significantly enhances hazard detection accuracy and speeds up data collection compared to traditional safety walks, which are limited by human observation and slower reporting. Drones equipped with sensors and AI provide continuous, precise surveillance, enabling immediate corrective actions to maintain workplace safety standards.

Digital Safety Twin

Digital Safety Twin technology enhances drone-based safety inspections by creating detailed virtual replicas of job sites, enabling real-time hazard identification and risk assessment without physical presence. Unlike traditional safety walks, this advanced method provides higher precision, continuous monitoring, and data-driven insights to proactively mitigate workplace accidents.

Visual Data-Driven Assessment

Safety Walks provide real-time, on-site hazard identification through direct human observation, ensuring contextual understanding of the environment, while Drone-Based Safety Inspections leverage high-resolution aerial imagery and thermal sensors to capture comprehensive visual data in hard-to-reach areas, enabling precise analysis and documentation. Combining these methods enhances safety assessments by merging human judgment with advanced imaging technology for thorough visual data-driven evaluation.

AI-Powered Incident Analytics

AI-powered incident analytics in drone-based safety inspections enable real-time hazard detection and predictive risk assessment, significantly enhancing workplace safety compared to traditional safety walks. These advanced systems analyze vast data sets from drone footage to identify patterns and prevent incidents, reducing human error and increasing operational efficiency.

Safety Walk vs Drone-Based Safety Inspection Infographic

industrydif.com

industrydif.com