Hazard assessment identifies potential risks and evaluates their likelihood and impact to prevent accidents involving pets. Bowtie analysis visualizes the relationship between hazards, preventive controls, and mitigation measures, offering a clear overview of safety barriers. Combining both methods enhances pet safety by systematically identifying risks and ensuring effective controls are in place.

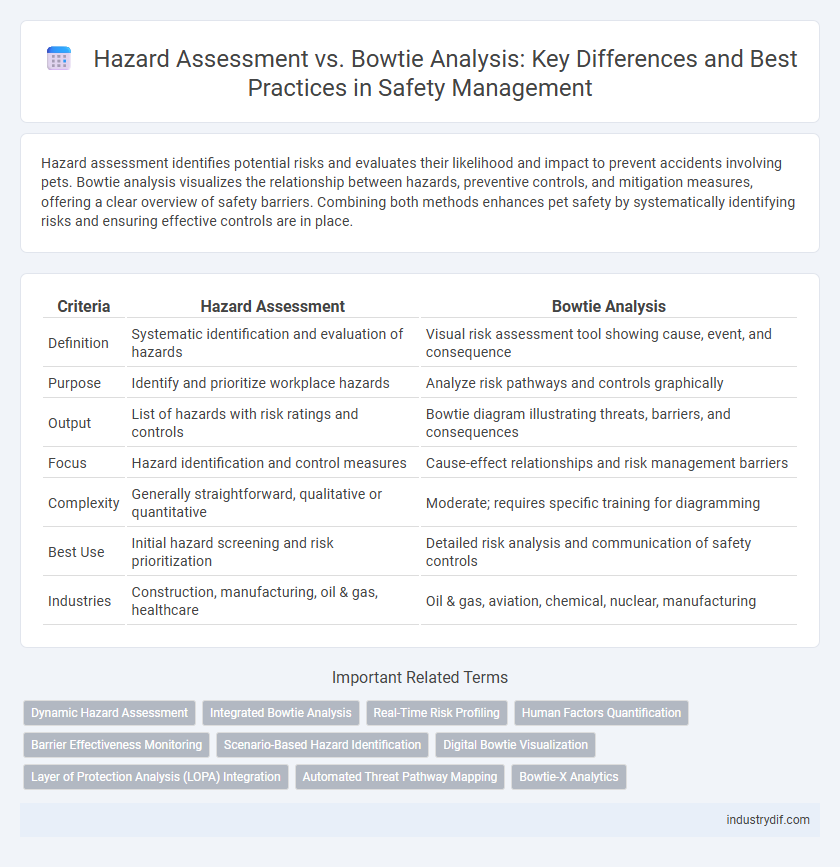

Table of Comparison

| Criteria | Hazard Assessment | Bowtie Analysis |

|---|---|---|

| Definition | Systematic identification and evaluation of hazards | Visual risk assessment tool showing cause, event, and consequence |

| Purpose | Identify and prioritize workplace hazards | Analyze risk pathways and controls graphically |

| Output | List of hazards with risk ratings and controls | Bowtie diagram illustrating threats, barriers, and consequences |

| Focus | Hazard identification and control measures | Cause-effect relationships and risk management barriers |

| Complexity | Generally straightforward, qualitative or quantitative | Moderate; requires specific training for diagramming |

| Best Use | Initial hazard screening and risk prioritization | Detailed risk analysis and communication of safety controls |

| Industries | Construction, manufacturing, oil & gas, healthcare | Oil & gas, aviation, chemical, nuclear, manufacturing |

Introduction to Hazard Assessment and Bowtie Analysis

Hazard assessment systematically identifies and evaluates risks associated with workplace activities, forming the foundation for effective safety management. Bowtie analysis visually maps the pathways from potential hazards to their consequences, highlighting preventive and mitigative controls. Combining hazard assessment with bowtie analysis enhances risk understanding and strengthens safety strategies.

Defining Hazard Assessment: Scope and Purpose

Hazard assessment identifies potential dangers in the workplace by systematically analyzing processes, materials, and environments to prevent accidents and injuries. It focuses on recognizing hazards, evaluating risks, and determining control measures within a defined scope, often specific to tasks or areas. Bowtie analysis expands on hazard assessment by visually mapping the pathways from hazards to consequences, highlighting preventive and mitigative controls, but hazard assessment remains essential for establishing the groundwork.

What is Bowtie Analysis? Methodology Overview

Bowtie Analysis is a risk evaluation method that visually maps out the pathways from potential hazards to their possible consequences, highlighting the preventive and mitigative controls in place. This methodology combines elements of fault tree and event tree analyses, providing a comprehensive overview of risk scenarios through a clear, bowtie-shaped diagram. By identifying critical control points and their interrelationships, Bowtie Analysis enhances hazard management and decision-making in safety-critical industries.

Key Differences Between Hazard Assessment and Bowtie Analysis

Hazard assessment systematically identifies and evaluates potential risks by examining hazards, exposure, and consequences, while bowtie analysis visually maps out the relationship between hazards, preventive controls, and mitigative barriers in a single diagram. Hazard assessment emphasizes risk quantification and prioritization, whereas bowtie analysis focuses on illustrating pathways from causes to consequences with control measures for easier communication and understanding. The bowtie method integrates both proactive and reactive safety measures, providing a comprehensive risk management tool compared to the more linear process of hazard assessment.

Industry Applications: When to Use Each Approach

Hazard Assessment is essential in industries like manufacturing and construction for identifying potential risks and implementing preventive measures early in project planning. Bowtie Analysis proves valuable in oil & gas and chemical sectors by visually mapping out risk pathways and barriers, facilitating clearer communication and control strategies. Selecting between the two depends on the complexity of operations and the need for detailed causal analysis versus general hazard identification.

Steps in Conducting a Hazard Assessment

Hazard assessment involves identifying potential hazards, evaluating the risks associated with each hazard, and implementing control measures to mitigate those risks. Key steps include hazard identification through workplace inspections and employee input, risk analysis by determining the likelihood and severity of incidents, and prioritizing hazards for corrective action. This structured approach ensures a thorough understanding of safety risks before progressing to methods like Bowtie Analysis for detailed risk management.

Implementation Process of Bowtie Analysis

The implementation process of Bowtie Analysis involves identifying key hazards, potential threats, and consequences by constructing a visual diagram that links causes to controls and outcomes. This method enables organizations to systematically evaluate risk controls' effectiveness and ensures clear communication of hazard scenarios across teams. Compared to traditional hazard assessments, Bowtie Analysis offers a more dynamic and integrated approach to managing safety risks in complex environments.

Benefits and Limitations: Hazard Assessment vs Bowtie Analysis

Hazard assessment systematically identifies potential risks by evaluating the likelihood and severity of hazards, offering a clear prioritization framework but often lacks visualization of control measures and their interrelationships. Bowtie analysis provides a graphical representation that links causes, preventive controls, and mitigation measures, enhancing understanding of risk pathways and communication among stakeholders, though it can be resource-intensive and requires detailed data input. Both methods complement each other, with hazard assessment grounding risk prioritization and bowtie analysis improving risk management clarity and decision-making.

Integrating Hazard Assessment and Bowtie Analysis in Safety Management

Integrating hazard assessment and bowtie analysis enhances safety management by systematically identifying hazards and visualizing risk control measures through fault and barrier pathways. This combined approach enables organizations to prioritize safety interventions based on comprehensive risk evaluations, improving decision-making effectiveness. Enhanced clarity in cause-and-effect relationships within bowtie diagrams supports proactive hazard mitigation strategies and continuous safety performance monitoring.

Best Practices for Effective Risk Management in Industrial Safety

Hazard assessment identifies potential sources of harm in industrial settings by systematically evaluating processes, equipment, and environments to prioritize risks effectively. Bowtie analysis visualizes the relationship between hazards, preventive barriers, and mitigation controls, enhancing clarity in managing risk pathways. Integrating both methods ensures comprehensive risk identification and control strategy development, promoting a robust safety culture and minimizing incident frequency.

Related Important Terms

Dynamic Hazard Assessment

Dynamic hazard assessment continuously evaluates evolving risks in real-time, enabling proactive responses to prevent incidents, whereas traditional bowtie analysis provides a static, visual representation of hazard control measures and potential failure points. Emphasizing dynamic assessment enhances operational safety by integrating situational awareness with immediate risk mitigation strategies.

Integrated Bowtie Analysis

Integrated Bowtie Analysis offers a comprehensive hazard assessment by visually mapping potential risk pathways and critical control measures within a single framework, enhancing understanding and communication of safety threats and mitigation strategies. This approach surpasses traditional hazard assessments by combining qualitative and quantitative data, enabling more effective identification, prevention, and management of hazards across complex systems.

Real-Time Risk Profiling

Hazard Assessment identifies potential risks by systematically evaluating workplace conditions, while Bowtie Analysis visually maps out pathways from hazards to consequences, enhancing understanding of controls. Real-time risk profiling integrates live data with Bowtie frameworks to dynamically monitor and respond to evolving hazards, improving proactive safety management.

Human Factors Quantification

Hazard assessment primarily identifies and categorizes potential risks, whereas Bowtie analysis visually maps out preventive and mitigative barriers, integrating human factors quantification to evaluate operator reliability and error probability. Quantifying human factors in Bowtie analysis enhances safety management by systematically addressing cognitive and behavioral risks, reducing incident likelihood through targeted interventions.

Barrier Effectiveness Monitoring

Hazard assessment identifies potential risks and their causes, while Bowtie Analysis visually maps hazards, preventive barriers, and recovery controls to evaluate barrier effectiveness monitoring. Effective barrier monitoring ensures real-time verification of control performance, reducing incident likelihood and enhancing overall safety management.

Scenario-Based Hazard Identification

Scenario-based hazard identification using Bowtie Analysis provides a visual framework that links potential hazards to preventive and mitigating controls, enhancing the clarity of risk pathways compared to traditional hazard assessments. This method allows for a more dynamic understanding of complex scenarios, facilitating targeted safety measures and improved hazard communication across teams.

Digital Bowtie Visualization

Hazard assessment identifies potential risks through systematic evaluation, while Bowtie Analysis visually maps the pathways from hazards to outcomes, highlighting preventive and mitigative barriers. Digital Bowtie Visualization enhances this process by providing interactive, real-time monitoring of safety controls, improving risk communication and decision-making in complex environments.

Layer of Protection Analysis (LOPA) Integration

Hazard Assessment identifies potential risks and their causes, while Bowtie Analysis visually maps hazard prevention and mitigation barriers, enabling clearer communication of risk pathways; integrating Layer of Protection Analysis (LOPA) quantifies the effectiveness of these layers, enhancing decision-making by assigning risk reduction values to each protective barrier in complex safety systems. LOPA integration with Bowtie Analysis improves hazard management by combining qualitative visualization with quantitative risk assessment, ensuring comprehensive evaluation of safety layers and prioritizing resource allocation for optimal risk reduction.

Automated Threat Pathway Mapping

Hazard assessment identifies potential risks through systematic evaluation, while Bowtie Analysis visualizes causal relationships using automated threat pathway mapping to enhance proactive safety management. Automated threat pathway mapping in Bowtie Analysis provides clear visualization of risk controls and barriers, improving hazard mitigation effectiveness compared to traditional hazard assessment methods.

Bowtie-X Analytics

Bowtie-X Analytics enhances traditional hazard assessment by providing a detailed visualization of risk pathways and control measures, enabling real-time monitoring and proactive risk management. This advanced tool integrates data-driven insights to identify vulnerabilities and optimize safety controls more effectively than conventional hazard assessment methods.

Hazard Assessment vs Bowtie Analysis Infographic

industrydif.com

industrydif.com