Hazard identification involves systematically recognizing potential sources of harm to pets, such as toxic plants or unsafe household items. Predictive risk modeling uses data and algorithms to forecast possible safety threats based on pet behavior and environmental factors. Combining these approaches enhances proactive pet safety by addressing both known dangers and emerging risks.

Table of Comparison

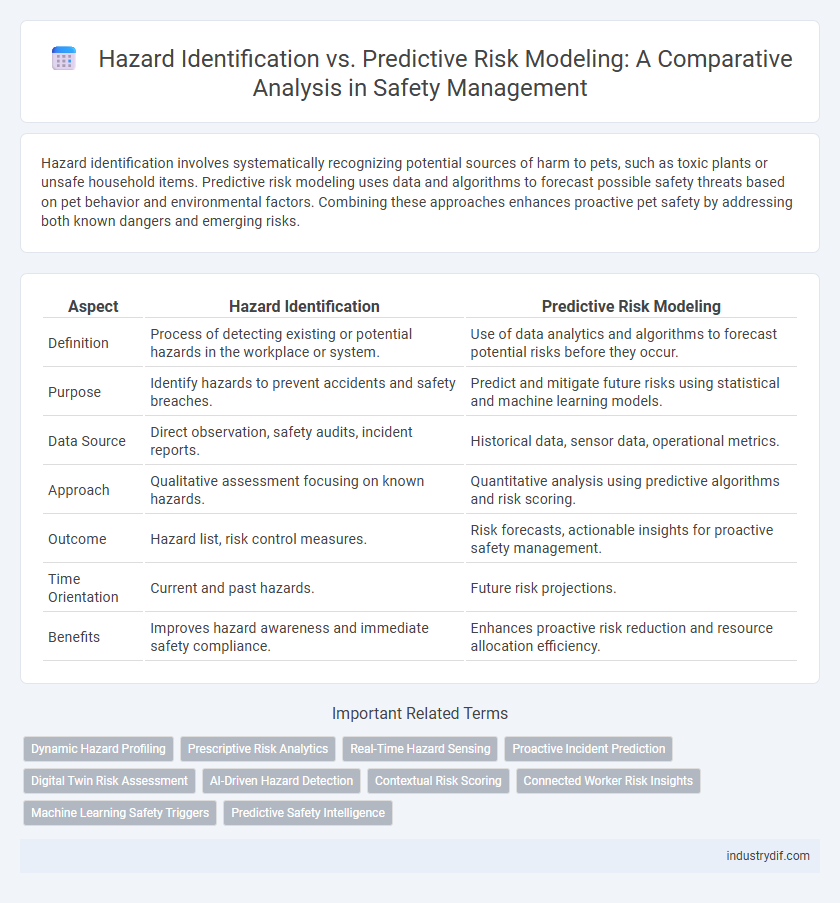

| Aspect | Hazard Identification | Predictive Risk Modeling |

|---|---|---|

| Definition | Process of detecting existing or potential hazards in the workplace or system. | Use of data analytics and algorithms to forecast potential risks before they occur. |

| Purpose | Identify hazards to prevent accidents and safety breaches. | Predict and mitigate future risks using statistical and machine learning models. |

| Data Source | Direct observation, safety audits, incident reports. | Historical data, sensor data, operational metrics. |

| Approach | Qualitative assessment focusing on known hazards. | Quantitative analysis using predictive algorithms and risk scoring. |

| Outcome | Hazard list, risk control measures. | Risk forecasts, actionable insights for proactive safety management. |

| Time Orientation | Current and past hazards. | Future risk projections. |

| Benefits | Improves hazard awareness and immediate safety compliance. | Enhances proactive risk reduction and resource allocation efficiency. |

Introduction to Hazard Identification and Predictive Risk Modeling

Hazard identification involves systematically recognizing potential sources of harm in the workplace, using methods such as inspections, audits, and employee feedback to prevent accidents. Predictive risk modeling employs data analytics and statistical techniques to forecast the likelihood and impact of hazards before they occur, enabling proactive safety measures. Combining these approaches enhances safety management by addressing both current hazards and future risks with data-driven precision.

Defining Hazard Identification in Safety Management

Hazard Identification in safety management involves systematically recognizing potential sources of harm or dangerous conditions in the workplace to prevent accidents. This process uses tools such as hazard checklists, inspections, and employee reports to document and assess risks before they lead to incidents. Effective hazard identification serves as the foundation for developing controls and informs predictive risk modeling by providing accurate data on existing hazards.

Principles of Predictive Risk Modeling

Predictive Risk Modeling relies on data-driven algorithms to forecast potential hazards by analyzing historical incident records, environmental factors, and operational variables. Its principles emphasize continuous data collection, pattern recognition, and probabilistic risk assessment to anticipate and mitigate safety threats before they manifest. This approach contrasts with traditional Hazard Identification, which primarily focuses on recognizing existing risks through inspections and audits rather than forecasting future events.

Key Differences Between Hazard Identification and Predictive Risk Modeling

Hazard Identification involves systematically recognizing and documenting potential sources of harm within a specific environment, focusing on current and known dangers to ensure immediate safety measures. Predictive Risk Modeling uses statistical and machine learning techniques to analyze historical data and forecast future risks, enabling proactive prevention strategies. The key difference lies in Hazard Identification's emphasis on present hazards versus Predictive Risk Modeling's forward-looking approach to risk anticipation and mitigation.

Benefits of Traditional Hazard Identification

Traditional hazard identification provides a direct and tangible assessment of workplace dangers through physical inspections and employee observations, ensuring immediate recognition of visible risks. This method leverages historical data and experienced personnel to pinpoint established hazards, facilitating straightforward compliance with safety regulations. It enables organizations to implement targeted control measures promptly, reducing the likelihood of accidents and promoting a safer work environment.

Advantages of Predictive Risk Modeling in Modern Safety

Predictive risk modeling leverages advanced analytics and big data to identify potential hazards before they manifest, enhancing proactive safety management. Unlike traditional hazard identification, it quantifies risk probabilities, enabling targeted interventions and resource optimization in industries such as manufacturing, construction, and healthcare. Real-time monitoring and machine learning algorithms improve predictive accuracy, reducing workplace accidents and ensuring regulatory compliance.

Integrating Hazard Identification with Predictive Analytics

Integrating hazard identification with predictive risk modeling enhances workplace safety by combining real-time data analysis and historical incident patterns to proactively identify potential risks. This hybrid approach leverages machine learning algorithms to predict future hazards, enabling organizations to implement preventive measures before incidents occur. Effective integration increases accuracy in risk assessment, reduces unexpected accidents, and supports continuous improvement in safety management systems.

Common Challenges in Hazard Identification and Predictive Modeling

Hazard identification and predictive risk modeling both face challenges including data incompleteness, which limits accurate risk assessment, and the complexity of interpreting diverse environmental and operational variables. The unpredictability of rare but high-impact events complicates hazard identification, while predictive models struggle with biases inherent in historical data and dynamic process changes. Integrating qualitative expert judgment with quantitative modeling remains essential yet challenging to enhance the reliability of hazard evaluation and risk prediction.

Case Studies: Real-World Applications in Industry

Case studies in safety management demonstrate that hazard identification systematically detects potential dangers through observational techniques and historical data analysis, while predictive risk modeling utilizes statistical algorithms and machine learning to forecast incidents before they occur. In industries such as oil and gas, manufacturing, and construction, predictive risk modeling has effectively reduced accidents by identifying high-risk scenarios through sensor data and operational metrics. Real-world applications reveal that integrating hazard identification with predictive risk models enhances proactive safety measures, resulting in a significant decrease in workplace injuries and downtime.

Future Trends in Safety: Evolving Risk Assessment Approaches

Hazard Identification focuses on recognizing existing dangers within a workplace, while Predictive Risk Modeling utilizes data analytics and machine learning to forecast potential safety incidents before they occur. Emerging trends in safety emphasize integrating IoT sensors and AI-driven algorithms to enhance predictive accuracy and real-time monitoring capabilities. These advancements enable organizations to shift from reactive hazard management to proactive risk mitigation, significantly reducing workplace accidents and improving overall safety culture.

Related Important Terms

Dynamic Hazard Profiling

Dynamic Hazard Profiling enhances traditional hazard identification by continuously integrating real-time data and predictive analytics to anticipate emerging risks, enabling proactive safety interventions. Unlike static assessments, predictive risk modeling leverages machine learning algorithms to analyze patterns and trends, offering a forward-looking approach that improves hazard detection accuracy and response time.

Prescriptive Risk Analytics

Prescriptive risk analytics leverages hazard identification data and predictive risk modeling to recommend specific safety interventions and optimize decision-making processes. By integrating real-time hazard detection with predictive insights, prescriptive analytics provides actionable risk mitigation strategies that enhance workplace safety and reduce incident rates.

Real-Time Hazard Sensing

Real-time hazard sensing enhances workplace safety by continuously monitoring environmental conditions and equipment status, enabling immediate detection of potential threats. Predictive risk modeling anticipates hazards based on historical data and trends, while hazard identification provides a snapshot of existing risks, but real-time sensing offers dynamic, actionable insights for proactive intervention.

Proactive Incident Prediction

Hazard identification relies on recognizing existing workplace dangers through inspections and audits, while predictive risk modeling uses data analytics and machine learning algorithms to forecast potential incidents before they occur. Proactive incident prediction enhances safety by enabling targeted interventions based on patterns in historical incident data and real-time environmental inputs.

Digital Twin Risk Assessment

Hazard identification involves recognizing potential sources of harm, whereas predictive risk modeling uses data-driven algorithms to forecast possible safety incidents. Digital Twin Risk Assessment enhances predictive accuracy by creating virtual replicas of physical systems, enabling continuous monitoring and proactive hazard mitigation in real-time.

AI-Driven Hazard Detection

AI-driven hazard detection enhances predictive risk modeling by continuously analyzing real-time data to identify potential safety threats before they materialize, improving workplace hazard identification accuracy and timeliness. Integrating machine learning algorithms enables proactive risk mitigation strategies by forecasting hazard patterns beyond traditional inspection methods.

Contextual Risk Scoring

Hazard Identification systematically detects potential dangers based on historical and observed data, while Predictive Risk Modeling employs algorithms and machine learning to forecast future incidents through Contextual Risk Scoring. Contextual Risk Scoring enhances safety by integrating environmental factors, real-time data, and operational context to prioritize risks more accurately.

Connected Worker Risk Insights

Hazard identification involves recognizing existing workplace dangers, while predictive risk modeling uses data analytics and machine learning to forecast potential incidents before they occur, enhancing connected worker risk insights. Integrating real-time sensor data from wearable devices with predictive models enables proactive intervention, significantly reducing workplace accidents and improving overall safety management.

Machine Learning Safety Triggers

Hazard identification relies on recognizing existing safety risks through historical and observational data, while predictive risk modeling uses machine learning safety triggers to forecast potential hazards by analyzing patterns and anomalies in real-time sensor data. Machine learning algorithms enhance hazard detection by continuously learning from diverse datasets, enabling proactive interventions and reducing workplace incidents.

Predictive Safety Intelligence

Predictive Risk Modeling enhances safety by leveraging data analytics and machine learning algorithms to forecast potential hazards before they occur, enabling proactive interventions. This approach in Predictive Safety Intelligence transforms traditional hazard identification into a dynamic process, significantly reducing workplace accidents through real-time risk assessment and mitigation strategies.

Hazard Identification vs Predictive Risk Modeling Infographic

industrydif.com

industrydif.com