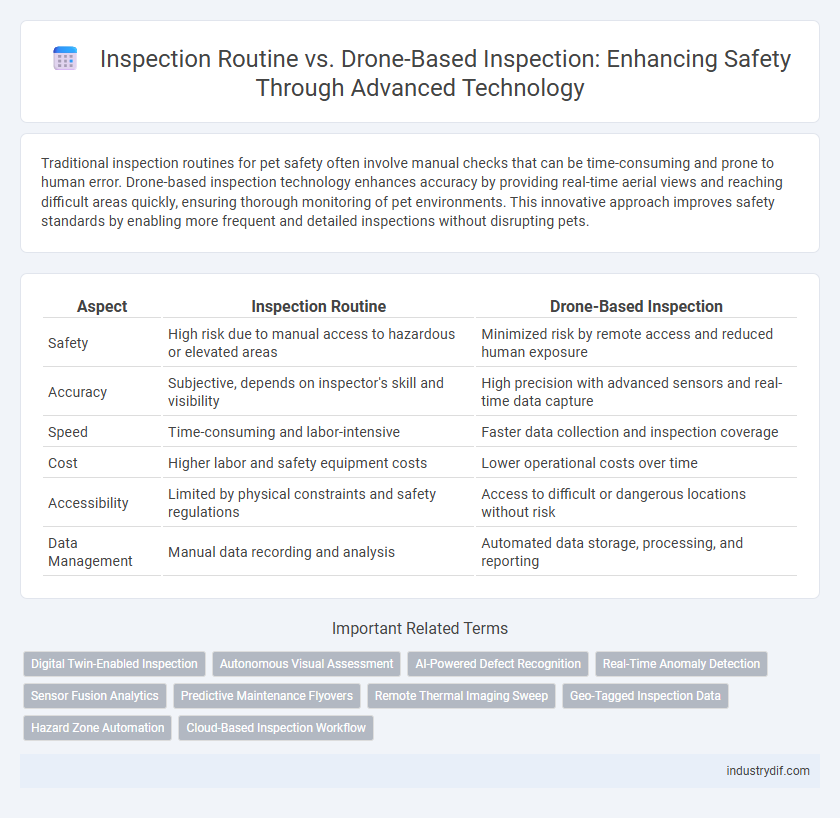

Traditional inspection routines for pet safety often involve manual checks that can be time-consuming and prone to human error. Drone-based inspection technology enhances accuracy by providing real-time aerial views and reaching difficult areas quickly, ensuring thorough monitoring of pet environments. This innovative approach improves safety standards by enabling more frequent and detailed inspections without disrupting pets.

Table of Comparison

| Aspect | Inspection Routine | Drone-Based Inspection |

|---|---|---|

| Safety | High risk due to manual access to hazardous or elevated areas | Minimized risk by remote access and reduced human exposure |

| Accuracy | Subjective, depends on inspector's skill and visibility | High precision with advanced sensors and real-time data capture |

| Speed | Time-consuming and labor-intensive | Faster data collection and inspection coverage |

| Cost | Higher labor and safety equipment costs | Lower operational costs over time |

| Accessibility | Limited by physical constraints and safety regulations | Access to difficult or dangerous locations without risk |

| Data Management | Manual data recording and analysis | Automated data storage, processing, and reporting |

Overview of Traditional Inspection Routines

Traditional inspection routines rely heavily on manual visual assessments conducted by trained professionals using tools such as ladders, scaffolding, and handheld devices. These time-intensive methods often require physical access to challenging environments, increasing safety risks for inspectors and causing potential downtime. Despite being established and standardized, manual inspections are limited by human error and slower data collection compared to drone-based alternatives.

Introduction to Drone-Based Inspection Technology

Drone-based inspection technology leverages unmanned aerial vehicles (UAVs) equipped with high-resolution cameras and sensors to perform detailed safety evaluations of infrastructure. This innovative approach enhances inspection efficiency by accessing hard-to-reach areas while minimizing human exposure to hazardous environments. Integrating thermal imaging and real-time data transmission, drone inspections provide comprehensive safety assessments with increased accuracy and reduced downtime.

Key Differences Between Manual and Drone Inspections

Manual inspections rely on human inspectors physically accessing sites, which can pose safety risks and limit thoroughness in hazardous or hard-to-reach areas. Drone-based inspections utilize unmanned aerial vehicles equipped with high-resolution cameras and sensors to capture detailed data remotely, enhancing safety and enabling access to confined or elevated spaces. The automated nature of drones reduces human exposure to dangers, increases inspection speed, and provides precise, real-time data for improved decision-making.

Safety Benefits of Drone-Based Inspection

Drone-based inspection enhances safety by eliminating the need for workers to access hazardous or hard-to-reach areas, significantly reducing the risk of falls and accidents. Equipped with high-resolution cameras and sensors, drones provide detailed visual data remotely, allowing for thorough assessments without physical presence in dangerous environments. This technology also minimizes exposure to harmful substances and extreme weather conditions, promoting safer inspection practices overall.

Efficiency and Time Savings Comparison

Drone-based inspections significantly reduce safety risks by accessing hazardous or hard-to-reach areas without endangering personnel. Traditional inspection routines often require extensive setup and manual labor, resulting in longer inspection times and increased downtime. Utilizing drones improves efficiency through rapid data collection and real-time analysis, leading to faster decision-making and substantial time savings.

Cost Implications: Routine vs Drone-Based Inspection

Routine inspections often involve significant labor costs, equipment downtime, and manual data recording, which can elevate overall expenses. Drone-based inspections reduce labor requirements and operational disruptions, offering cost-effective, rapid data collection with enhanced precision. Over time, integrating drone technology minimizes maintenance expenses and improves safety outcomes by enabling more frequent and detailed monitoring.

Accuracy and Data Quality Analysis

Drone-based inspection enhances accuracy by capturing high-resolution images and real-time data from difficult-to-reach areas, reducing human error inherent in manual inspections. The advanced sensors and AI-driven analytics in drones provide superior data quality, enabling precise anomaly detection and comprehensive asset condition assessment. Compared to traditional inspection routines, drones deliver faster, more consistent, and quantifiable results, optimizing safety protocols and minimizing risk exposure for inspection teams.

Regulatory Considerations and Compliance

Inspection routines must adhere strictly to occupational safety regulations and industry standards to ensure compliance and minimize risk. Drone-based inspections require operators to follow specific aviation rules, obtain necessary permits, and maintain data security measures to align with regulatory frameworks. Incorporating drones can streamline inspection processes while meeting compliance demands, but thorough understanding of evolving legal requirements remains critical.

Industry Applications and Case Studies

Inspection routines in industries such as oil and gas, construction, and manufacturing have evolved with drone-based inspections offering enhanced safety and efficiency benefits. Case studies reveal that drone technology reduces human exposure to hazardous environments by enabling remote visual assessments of pipelines, power lines, and infrastructure while delivering high-resolution data for early defect detection. Companies adopting drone inspections report fewer accidents, lower operational downtime, and improved regulatory compliance compared to traditional manual inspection methods.

Future Trends in Safety Inspection Methods

Drone-based inspection methods are rapidly transforming safety protocols by enabling real-time data collection, reducing human exposure to hazardous environments, and increasing precision through high-resolution imaging. Traditional inspection routines often rely on manual checks, which can be time-consuming and prone to human error, whereas drones equipped with advanced sensors and AI analytics improve accuracy and efficiency. Future trends emphasize integrating autonomous drone fleets with predictive maintenance algorithms and digital twin technology, enhancing proactive safety management across industries.

Related Important Terms

Digital Twin-Enabled Inspection

Digital twin-enabled inspection enhances safety by providing real-time, high-fidelity simulations that identify potential hazards without physical exposure, enabling proactive maintenance and risk mitigation. Compared to traditional inspection routines, drone-based digital twin inspections offer comprehensive data collection, faster analysis, and precise anomaly detection in hard-to-reach or hazardous environments.

Autonomous Visual Assessment

Drone-based inspection utilizing autonomous visual assessment enhances safety by reducing human exposure to hazardous environments and enabling real-time data collection with high-resolution imaging. This technology streamlines routine inspections through precise, automated anomaly detection, minimizing human error and improving overall site safety management.

AI-Powered Defect Recognition

AI-powered defect recognition in drone-based inspections significantly enhances accuracy and speed compared to traditional inspection routines by utilizing advanced machine learning algorithms to identify safety hazards and structural defects in real time. This technology reduces human error, improves risk assessment, and enables proactive maintenance, ensuring higher safety standards across industrial and infrastructure environments.

Real-Time Anomaly Detection

Drone-based inspection enables real-time anomaly detection by using advanced sensors and AI algorithms to identify hazards immediately, significantly reducing response time compared to traditional inspection routines. This proactive approach enhances safety by providing continuous monitoring and instant alerts, minimizing the risk of undetected structural issues.

Sensor Fusion Analytics

Sensor fusion analytics enhances drone-based inspection by integrating data from multiple sensors such as LiDAR, thermal imaging, and high-resolution cameras, resulting in comprehensive safety assessments that surpass traditional routine inspections. This technology enables real-time anomaly detection and predictive maintenance, significantly reducing human error and improving hazard identification accuracy in safety-critical environments.

Predictive Maintenance Flyovers

Predictive maintenance flyovers utilizing drone-based inspections provide real-time data and high-resolution imagery, enabling early detection of equipment wear and potential failures. This approach significantly reduces downtime and enhances safety by identifying hazards before routine inspections typically reveal them.

Remote Thermal Imaging Sweep

Remote thermal imaging sweeps conducted by drone-based inspections enhance safety by detecting heat anomalies in hard-to-reach areas without exposing personnel to hazardous environments. This method accelerates inspection routines, reduces human error, and provides high-resolution thermal data critical for preventative maintenance and early fault detection.

Geo-Tagged Inspection Data

Geo-tagged inspection data captured via drone-based inspections enhances safety by providing accurate, real-time location information critical for identifying hazards and monitoring structural integrity. Traditional inspection routines often lack precise spatial data, limiting timely decision-making and risk mitigation in safety management.

Hazard Zone Automation

Drone-based inspection enhances hazard zone safety by enabling automated data collection without exposing workers to dangerous environments, reducing the risk of accidents during routine inspections. Traditional inspection routines require manual presence, increasing the potential for human error and injury in high-risk areas.

Cloud-Based Inspection Workflow

Cloud-based inspection workflows enhance safety by enabling real-time data access and analysis during both traditional routine inspections and drone-based inspections. Centralized cloud platforms streamline the inspection process, improve accuracy, and facilitate rapid decision-making, reducing human error and exposure to hazardous environments.

Inspection Routine vs Drone-Based Inspection Infographic

industrydif.com

industrydif.com