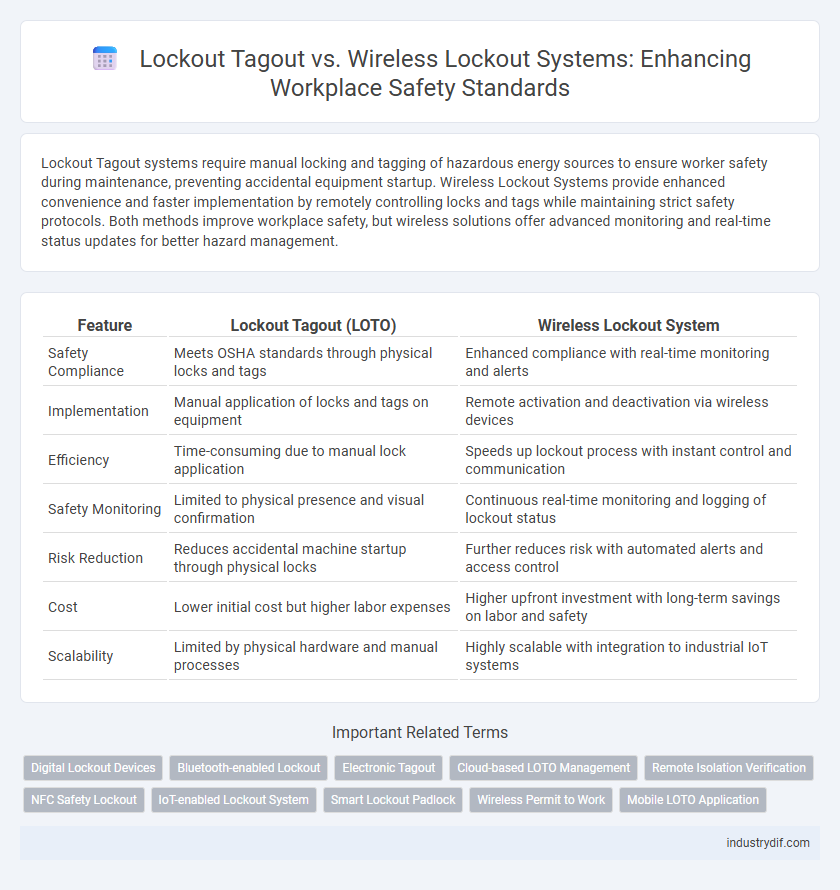

Lockout Tagout systems require manual locking and tagging of hazardous energy sources to ensure worker safety during maintenance, preventing accidental equipment startup. Wireless Lockout Systems provide enhanced convenience and faster implementation by remotely controlling locks and tags while maintaining strict safety protocols. Both methods improve workplace safety, but wireless solutions offer advanced monitoring and real-time status updates for better hazard management.

Table of Comparison

| Feature | Lockout Tagout (LOTO) | Wireless Lockout System |

|---|---|---|

| Safety Compliance | Meets OSHA standards through physical locks and tags | Enhanced compliance with real-time monitoring and alerts |

| Implementation | Manual application of locks and tags on equipment | Remote activation and deactivation via wireless devices |

| Efficiency | Time-consuming due to manual lock application | Speeds up lockout process with instant control and communication |

| Safety Monitoring | Limited to physical presence and visual confirmation | Continuous real-time monitoring and logging of lockout status |

| Risk Reduction | Reduces accidental machine startup through physical locks | Further reduces risk with automated alerts and access control |

| Cost | Lower initial cost but higher labor expenses | Higher upfront investment with long-term savings on labor and safety |

| Scalability | Limited by physical hardware and manual processes | Highly scalable with integration to industrial IoT systems |

Understanding Lockout Tagout (LOTO) Procedures

Lockout Tagout (LOTO) procedures ensure workplace safety by isolating energy sources to prevent accidental machinery startup during maintenance. Traditional LOTO relies on physical locks and tags that clearly indicate equipment is under maintenance, significantly reducing the risk of electrical, mechanical, or hydraulic hazards. Wireless lockout systems enhance LOTO by enabling remote control and monitoring, increasing efficiency while maintaining strict adherence to safety standards.

Evolution of Safety: Introduction to Wireless Lockout Systems

Wireless lockout systems represent a significant evolution in safety protocols by eliminating the need for physical lock devices, reducing human error and improving efficiency during maintenance procedures. These systems utilize secure wireless communication to control energy sources remotely, enabling faster lockout/tagout processes while ensuring compliance with OSHA standards. The integration of advanced technology enhances worker protection by providing real-time monitoring and instant updates on lockout status, thus minimizing risks of accidental machine startups.

Key Components of Traditional LOTO Systems

Traditional Lockout Tagout (LOTO) systems primarily consist of durable padlocks, standardized lockout hasps, and durable tags to ensure machinery is securely isolated during maintenance. These key components emphasize physical isolation of energy sources, preventing accidental machine startup and safeguarding workers from hazardous energy release. Their reliability and simplicity make them a foundational safety measure in industrial settings, contrasting with emerging wireless lockout technologies.

How Wireless Lockout Systems Work

Wireless lockout systems utilize radio-frequency identification (RFID) or Bluetooth technology to remotely control lockout/tagout devices on machinery, enhancing safety by minimizing the need for physical presence near hazardous equipment. These systems allow authorized personnel to apply and remove lockout tags electronically, ensuring real-time monitoring, audit trails, and rapid response during maintenance or emergency situations. Integrating wireless lockout systems improves compliance with OSHA lockout/tagout standards by reducing human error and providing centralized management of energy isolation procedures.

Compliance with OSHA: LOTO vs Wireless Solutions

OSHA's Lockout Tagout (LOTO) standard mandates strict control of hazardous energy during equipment maintenance to prevent workplace injuries. Traditional LOTO methods utilize physical locks and tags, ensuring direct, visible control over energy sources, while wireless lockout systems leverage digital technology for remote management, enhancing real-time monitoring and audit trails. Both systems aim to comply with OSHA requirements, but wireless solutions offer improved efficiency and documentation that support more robust compliance and safety program integration.

Risk Assessment and Hazard Control

Lockout Tagout (LOTO) requires thorough risk assessment to identify energy sources and implement physical lock devices, ensuring hazard control by isolating equipment from accidental energization. Wireless Lockout Systems enhance risk assessment accuracy through remote monitoring and real-time alerts, reducing human error and improving hazard control by enabling faster response to unauthorized access. Integrating wireless technology with traditional LOTO protocols strengthens overall safety by combining physical isolation with dynamic hazard management.

Pros and Cons: Manual LOTO vs Wireless Lockout

Manual Lockout Tagout (LOTO) systems provide a reliable, low-cost safety solution with straightforward implementation and minimal technical requirements, but they are prone to human error, misplacement of locks, and limited real-time control. Wireless lockout systems enhance safety through remote monitoring, automatic updates, and instant communication, reducing human error and enabling efficient management across multiple locations; however, they require significant initial investment, ongoing maintenance, and depend on robust wireless infrastructure. Choosing between manual and wireless lockout depends on factors such as facility size, budget, and the critical need for real-time oversight versus simplicity.

Implementation Challenges and Best Practices

Implementing traditional Lockout Tagout (LOTO) systems often faces challenges such as human error, time-consuming manual processes, and difficulty in tracking compliance. Wireless Lockout Systems offer enhanced real-time monitoring, remote control capabilities, and seamless integration with digital safety protocols, reducing the chances of unauthorized equipment activation. Best practices include thorough employee training, regular system audits, and leveraging smart technology to improve communication and ensure adherence to safety regulations.

Cost-Benefit Analysis of Safety Systems

Analyzing the cost-benefit of Lockout Tagout versus Wireless Lockout Systems reveals that traditional Lockout Tagout methods involve lower initial investment but incur higher labor costs and potential human error expenses over time. Wireless Lockout Systems require higher upfront technology costs but enhance efficiency, reduce downtime by up to 30%, and improve compliance through automated locking and tagging processes. Companies investing in wireless solutions report a decrease in workplace accidents related to hazardous energy by approximately 25%, translating into substantial long-term savings on injury-related costs and insurance premiums.

Future Trends in Industrial Safety Technologies

Emerging trends in industrial safety technologies reveal a shift from traditional Lockout Tagout (LOTO) methods toward Wireless Lockout Systems, which enhance real-time monitoring and remote control capabilities. Wireless systems integrate IoT devices and cloud-based platforms to facilitate instant hazard identification, improving worker safety and operational efficiency. These advancements signal a future where digitalization and connectivity drive more adaptive and proactive industrial safety protocols.

Related Important Terms

Digital Lockout Devices

Digital lockout devices in wireless lockout systems enhance safety by enabling real-time device status monitoring and remote control, reducing the risk of unauthorized energy release during maintenance. These digital systems provide audit trails and instant notifications, improving compliance with OSHA lockout/tagout standards compared to traditional mechanical lockout tagout methods.

Bluetooth-enabled Lockout

Bluetooth-enabled lockout systems enhance traditional lockout tagout (LOTO) procedures by enabling real-time monitoring and remote control of energy isolation devices, significantly reducing human error and improving worker safety. These wireless lockout systems facilitate instant communication and verification of lockout status, ensuring compliance with OSHA standards while increasing operational efficiency.

Electronic Tagout

Electronic Tagout in wireless lockout systems enhances safety by providing real-time status updates and remote control capabilities, reducing human error compared to traditional lockout tagout procedures. These systems enable instantaneous communication and audit trails, improving compliance and equipment protection in hazardous environments.

Cloud-based LOTO Management

Cloud-based Lockout Tagout (LOTO) management systems offer real-time remote monitoring and enhanced compliance tracking compared to traditional lockout tagout methods. Wireless lockout systems integrated with cloud platforms enable centralized control, automated reporting, and faster incident response, significantly improving workplace safety and operational efficiency.

Remote Isolation Verification

Remote isolation verification in wireless lockout systems enhances safety by enabling real-time status monitoring and control of hazardous energy sources without physical presence, reducing human error and exposure risks. Traditional lockout tagout methods rely on manual verification, which can delay isolation confirmation and increase the likelihood of accidental energization during maintenance.

NFC Safety Lockout

NFC Safety Lockout systems enhance traditional Lockout Tagout procedures by enabling wireless control and real-time monitoring of energy isolation devices, reducing human error and increasing compliance with OSHA safety standards. These smart systems leverage near-field communication technology to provide instant access permissions, audit trails, and remote lockout capabilities, improving workplace safety and efficiency.

IoT-enabled Lockout System

IoT-enabled wireless lockout systems enhance traditional Lockout Tagout (LOTO) procedures by providing real-time monitoring and remote control of energy isolation points, significantly reducing human error and unauthorized access. These advanced safety solutions leverage connected sensors and smart tags to ensure compliance, streamline audits, and improve worker safety in industrial environments.

Smart Lockout Padlock

Smart lockout padlocks in wireless lockout systems enhance safety by enabling real-time monitoring and remote control of energy isolation points, reducing human error and unauthorized access. These devices integrate with centralized software to streamline lockout tagout procedures, increasing efficiency and compliance with OSHA regulations.

Wireless Permit to Work

Wireless Permit to Work systems enhance safety by enabling real-time monitoring and remote control of lockout tagout processes, reducing human error and unauthorized access. Compared to traditional lockout tagout methods, wireless systems streamline permit issuance and compliance tracking, ensuring robustness in hazardous work environments.

Mobile LOTO Application

Mobile Lockout Tagout (LOTO) applications enhance safety by enabling real-time remote control and monitoring of lockout devices, reducing human error and improving compliance with OSHA standards. Wireless lockout systems integrated with mobile apps allow faster equipment isolation, digital tag updates, and audit trails, streamlining the lockout process while ensuring worker protection in hazardous environments.

Lockout Tagout vs Wireless Lockout System Infographic

industrydif.com

industrydif.com