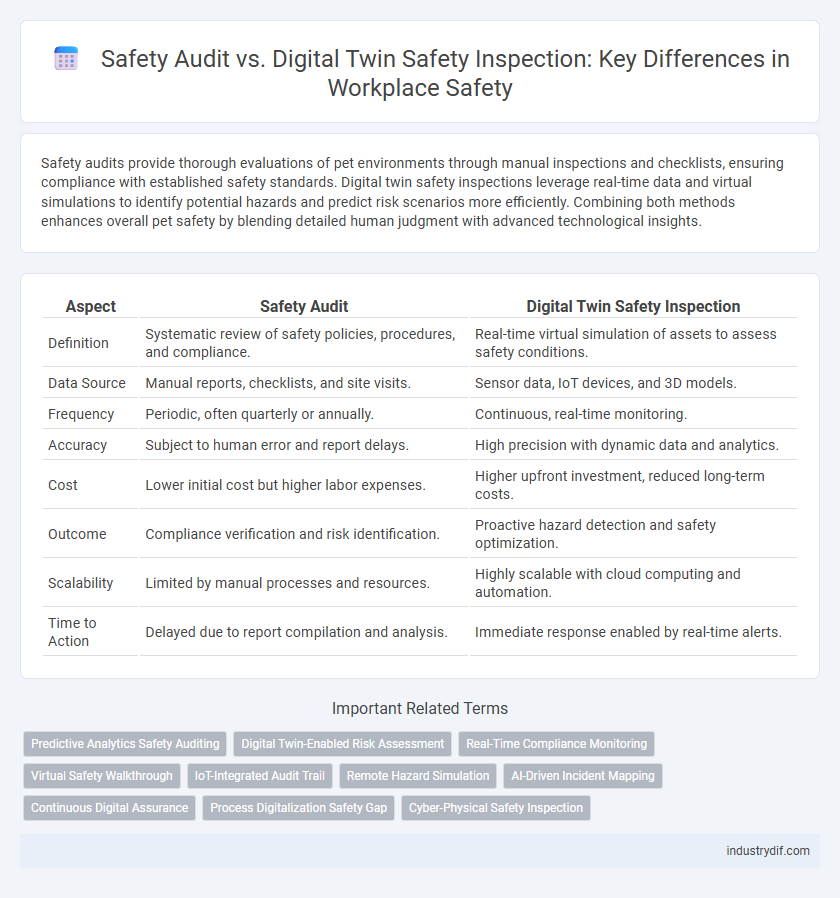

Safety audits provide thorough evaluations of pet environments through manual inspections and checklists, ensuring compliance with established safety standards. Digital twin safety inspections leverage real-time data and virtual simulations to identify potential hazards and predict risk scenarios more efficiently. Combining both methods enhances overall pet safety by blending detailed human judgment with advanced technological insights.

Table of Comparison

| Aspect | Safety Audit | Digital Twin Safety Inspection |

|---|---|---|

| Definition | Systematic review of safety policies, procedures, and compliance. | Real-time virtual simulation of assets to assess safety conditions. |

| Data Source | Manual reports, checklists, and site visits. | Sensor data, IoT devices, and 3D models. |

| Frequency | Periodic, often quarterly or annually. | Continuous, real-time monitoring. |

| Accuracy | Subject to human error and report delays. | High precision with dynamic data and analytics. |

| Cost | Lower initial cost but higher labor expenses. | Higher upfront investment, reduced long-term costs. |

| Outcome | Compliance verification and risk identification. | Proactive hazard detection and safety optimization. |

| Scalability | Limited by manual processes and resources. | Highly scalable with cloud computing and automation. |

| Time to Action | Delayed due to report compilation and analysis. | Immediate response enabled by real-time alerts. |

Understanding Safety Audits: Definition and Purpose

Safety audits systematically evaluate workplace conditions and compliance with regulatory standards to identify hazards and ensure employee protection. They involve comprehensive documentation, on-site inspections, and interviews to assess safety management systems and operational practices. The primary purpose is to detect risks early, reduce accidents, and promote continuous improvement in organizational safety culture.

What Are Digital Twin Safety Inspections?

Digital Twin Safety Inspections utilize real-time data and virtual replicas of physical assets to monitor safety conditions and predict potential hazards. Unlike traditional safety audits that rely on periodic manual checks, digital twins continuously analyze operational parameters, enabling proactive risk management. This innovative approach enhances accuracy, reduces downtime, and improves overall workplace safety by simulating scenarios and identifying vulnerabilities before incidents occur.

Key Differences Between Safety Audits and Digital Twin Inspections

Safety audits rely on manual data collection and periodic reviews to identify workplace hazards and ensure compliance with regulations, often leading to delayed detection of risks. Digital twin safety inspections utilize real-time, virtual replicas of physical assets to continuously monitor safety conditions, enabling proactive hazard identification and faster response times. The key difference lies in the static nature of traditional audits versus the dynamic, data-driven approach of digital twin inspections, which enhances accuracy and predictive maintenance capabilities.

Advantages of Traditional Safety Audits

Traditional safety audits offer the advantage of direct human observation, enabling auditors to identify subtle hazards and contextual risks that digital models may overlook. These audits provide real-time validation of compliance with safety protocols and allow immediate interaction with staff for clarification and corrective actions. Physical inspections also ensure that dynamic site-specific conditions and unforeseen changes are accurately assessed, which technology-based inspections might fail to capture comprehensively.

Benefits of Digital Twin Technology in Safety Inspections

Digital twin technology enhances safety inspections by providing real-time, accurate simulations of physical environments, allowing for early detection of potential hazards without disrupting operations. This technology enables continuous monitoring and predictive analysis, reducing risks through proactive maintenance and immediate response to safety issues. Compared to traditional safety audits, digital twin safety inspections improve accuracy, efficiency, and risk mitigation by integrating data-driven insights with virtual scenario testing.

Integration of Digital Twins in Safety Management Systems

Integrating digital twins in safety management systems enhances the precision and real-time monitoring capabilities compared to traditional safety audits by simulating operational environments and predicting potential hazards. Digital twin safety inspections enable continuous risk assessment and dynamic response adjustments, improving overall safety compliance. This integration facilitates proactive maintenance and incident prevention through data-driven insights and virtual scenario testing.

Common Challenges in Both Safety Audits and Digital Twin Inspections

Both safety audits and digital twin safety inspections face challenges in data accuracy, as incomplete or outdated information can lead to misleading risk assessments. Ensuring comprehensive hazard identification is difficult due to complex operational environments and evolving safety standards. Integrating diverse data sources while maintaining real-time monitoring capabilities also presents significant technical and operational hurdles.

Industry Use Cases: Safety Audits vs Digital Twin Inspections

Safety audits provide systematic, on-site evaluations of workplace hazards, ensuring compliance with industry regulations and identifying potential risks. Digital twin safety inspections leverage virtual replicas of physical assets to simulate hazardous scenarios and monitor real-time operational data, enhancing predictive maintenance and proactive risk management. Industries such as manufacturing, oil and gas, and construction utilize digital twins to complement traditional safety audits by enabling continuous, data-driven safety assessments and reducing downtime caused by unforeseen incidents.

Future Trends: Digitalization of Safety Assessments

Safety audits traditionally rely on manual inspections and periodic evaluations, whereas digital twin safety inspections leverage real-time data and virtual models to predict hazards and simulate scenarios. The future trend in safety assessments emphasizes digitalization, integrating IoT sensors and AI analytics within digital twins to enhance hazard detection accuracy and proactive risk management. This shift towards continuous, data-driven safety monitoring reduces downtime and supports dynamic compliance in industries like manufacturing, construction, and energy.

Choosing the Right Approach for Your Industry Safety Needs

Selecting the appropriate safety assessment method depends on industry-specific risks and operational complexity; traditional Safety Audits provide comprehensive compliance checks through manual inspections, while Digital Twin Safety Inspections offer real-time monitoring and predictive analytics by simulating physical assets digitally. Industries with dynamic environments like manufacturing or oil and gas benefit from Digital Twin technology's ability to anticipate hazards and optimize maintenance schedules, reducing downtime and enhancing worker safety. For sectors with established regulatory frameworks and standardized processes, conventional Safety Audits ensure adherence to safety standards and documentation requirements effectively.

Related Important Terms

Predictive Analytics Safety Auditing

Predictive analytics in digital twin safety inspection enables real-time hazard identification and risk mitigation by simulating various operational scenarios, surpassing traditional safety audit methods that rely on historical data and periodic assessments. Integrating IoT sensors with digital twin platforms allows continuous monitoring and proactive safety interventions, significantly reducing workplace incidents and enhancing compliance with safety regulations.

Digital Twin-Enabled Risk Assessment

Digital Twin-enabled risk assessment enhances traditional safety audits by providing real-time, dynamic simulations of workplace environments, enabling predictive identification of hazards and optimization of safety protocols. This technology integrates IoT data with virtual models to offer precise risk evaluation, reducing human error and improving regulatory compliance.

Real-Time Compliance Monitoring

Safety audits provide periodic assessments that identify compliance gaps through manual inspections, while digital twin safety inspections enable real-time compliance monitoring by creating dynamic, virtual replicas of physical environments. Real-time data integration in digital twins allows continuous hazard detection and immediate corrective actions, significantly improving workplace safety and regulatory adherence.

Virtual Safety Walkthrough

A Virtual Safety Walkthrough using Digital Twin technology enables real-time hazard identification and risk assessment by simulating physical environments accurately. Unlike traditional Safety Audits, which rely on periodic manual inspections, digital twins offer continuous monitoring and predictive analytics to enhance workplace safety proactively.

IoT-Integrated Audit Trail

Safety audits provide structured evaluations of workplace hazards based on periodic inspections, while digital twin safety inspections utilize real-time IoT-integrated audit trails to continuously monitor, analyze, and simulate safety conditions. The IoT-connected sensors and devices ensure accurate data collection, enabling predictive maintenance and proactive risk mitigation in complex industrial environments.

Remote Hazard Simulation

Remote hazard simulation in digital twin safety inspections enables real-time risk assessment by creating virtual replicas of physical environments, allowing for predictive hazard identification without on-site presence. Traditional safety audits lack this dynamic capability, relying on periodic manual evaluations that may miss transient or evolving risks.

AI-Driven Incident Mapping

AI-driven incident mapping in digital twin safety inspections enhances real-time hazard detection by creating dynamic, virtual replicas of facilities, allowing for proactive identification of risks that traditional safety audits may overlook. Unlike static safety audits, digital twin technology continuously analyzes data streams through AI algorithms, improving incident prediction accuracy and enabling timely interventions to prevent workplace accidents.

Continuous Digital Assurance

Safety audits provide periodic evaluations of compliance and risk, whereas digital twin safety inspections enable continuous digital assurance by simulating real-time operational conditions and identifying hazards proactively. Leveraging IoT sensors and advanced analytics, digital twins facilitate ongoing monitoring and rapid response to safety deviations, enhancing workplace safety beyond traditional audit methods.

Process Digitalization Safety Gap

Safety audits rely on manual inspections and checklists that often miss real-time process deviations, creating a digitalization safety gap in identifying hazards promptly. Digital twin safety inspections leverage real-time data synchronization and predictive analytics to continuously monitor and simulate operational conditions, closing the gap by enabling proactive risk mitigation.

Cyber-Physical Safety Inspection

Cyber-Physical Safety Inspection leverages digital twins to simulate and analyze real-time operational data, enabling proactive identification of potential safety risks that traditional Safety Audits might overlook. Integrating sensor data with virtual models facilitates continuous monitoring and dynamic risk assessment, enhancing overall safety management in complex industrial environments.

Safety Audit vs Digital Twin Safety Inspection Infographic

industrydif.com

industrydif.com