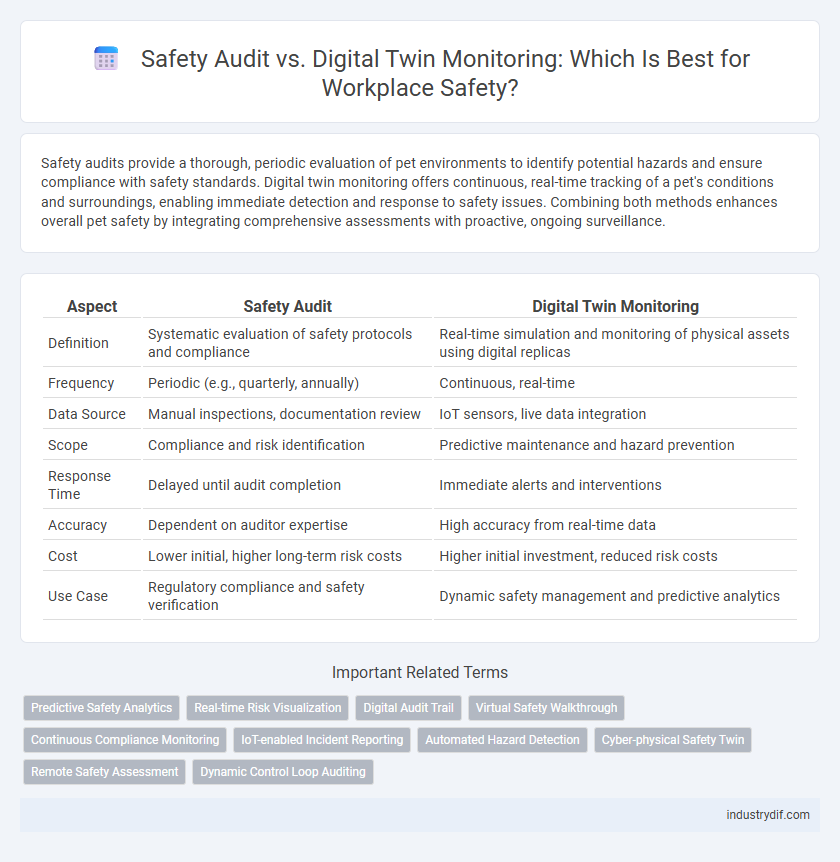

Safety audits provide a thorough, periodic evaluation of pet environments to identify potential hazards and ensure compliance with safety standards. Digital twin monitoring offers continuous, real-time tracking of a pet's conditions and surroundings, enabling immediate detection and response to safety issues. Combining both methods enhances overall pet safety by integrating comprehensive assessments with proactive, ongoing surveillance.

Table of Comparison

| Aspect | Safety Audit | Digital Twin Monitoring |

|---|---|---|

| Definition | Systematic evaluation of safety protocols and compliance | Real-time simulation and monitoring of physical assets using digital replicas |

| Frequency | Periodic (e.g., quarterly, annually) | Continuous, real-time |

| Data Source | Manual inspections, documentation review | IoT sensors, live data integration |

| Scope | Compliance and risk identification | Predictive maintenance and hazard prevention |

| Response Time | Delayed until audit completion | Immediate alerts and interventions |

| Accuracy | Dependent on auditor expertise | High accuracy from real-time data |

| Cost | Lower initial, higher long-term risk costs | Higher initial investment, reduced risk costs |

| Use Case | Regulatory compliance and safety verification | Dynamic safety management and predictive analytics |

Understanding Safety Audits in Industrial Settings

Safety audits in industrial settings systematically evaluate workplace hazards, compliance with regulations, and effectiveness of safety protocols to minimize risks and prevent accidents. These audits involve detailed inspections, documentation reviews, and employee interviews to identify potential safety gaps and ensure adherence to standards such as OSHA or ISO 45001. Integrating digital twin monitoring enhances traditional safety audits by providing real-time simulation data and predictive analytics for dynamic risk assessment and proactive incident prevention.

Introduction to Digital Twin Monitoring for Safety

Digital Twin Monitoring revolutionizes safety management by creating real-time virtual replicas of physical assets, enabling continuous hazard detection and predictive risk assessment. Unlike traditional safety audits that provide periodic evaluations, digital twins offer dynamic insights through sensor data integration and advanced analytics, allowing proactive incident prevention. This technology enhances decision-making by simulating scenarios and monitoring operational conditions, significantly improving workplace safety standards.

Key Differences Between Safety Audits and Digital Twin Monitoring

Safety audits involve systematic inspections and evaluations of physical work environments to identify hazards and ensure compliance with regulatory standards, emphasizing past and present safety conditions. Digital twin monitoring creates real-time, virtual replicas of physical assets or processes, enabling continuous safety performance tracking and predictive risk analysis through data integration from sensors and IoT devices. The key difference lies in safety audits being periodic, manual assessments versus digital twin monitoring offering ongoing, automated safety insights for proactive hazard prevention.

Benefits of Traditional Safety Audits

Traditional safety audits provide a comprehensive and systematic evaluation of workplace hazards through on-site inspections and direct employee interactions, ensuring compliance with established safety regulations. These audits help identify potential risks and operational inefficiencies by leveraging expert judgment and hands-on analysis that digital tools may overlook. The documented findings and corrective action plans from safety audits support continuous improvement and accountability in organizational safety management.

Advantages of Digital Twin-Based Safety Monitoring

Digital Twin-based safety monitoring provides real-time, continuous data analysis, enabling immediate detection of hazards and predictive maintenance to prevent accidents before they occur. This approach offers dynamic simulation of physical assets and environments, allowing for comprehensive risk assessment and scenario testing without disrupting actual operations. Enhanced accuracy and proactive intervention capabilities significantly reduce downtime and improve workplace safety compared to traditional periodic safety audits.

Limitations of Manual Safety Audits

Manual safety audits often suffer from inconsistencies and human error, limiting their ability to comprehensively identify hazards in complex environments. These audits rely on periodic inspections, which can miss real-time changes and emerging risks that digital twin monitoring continuously captures. Consequently, manual audits lack the dynamic data integration and predictive analytics provided by digital twins, reducing their effectiveness in proactive safety management.

Real-Time Hazard Identification with Digital Twins

Digital Twin monitoring enhances Safety Audits by enabling real-time hazard identification through continuous data integration from sensors and IoT devices. Unlike traditional Safety Audits that rely on periodic inspections, Digital Twins simulate operational environments dynamically, detecting potential risks instantly and allowing for proactive intervention. This real-time insight significantly reduces workplace accidents and improves compliance with safety regulations.

Integration of Digital Twin Technology in Safety Audits

Integrating digital twin technology in safety audits enhances real-time hazard detection and predictive risk assessment, allowing companies to simulate various operational scenarios without interrupting actual processes. Digital twins provide dynamic data visualization and continuous monitoring, bridging the gap between theoretical safety protocols and practical implementation. This fusion of virtual models and traditional audit methods boosts accuracy, accelerates decision-making, and optimizes overall workplace safety management systems.

Cost-Effectiveness: Audit vs Digital Twin Monitoring

Safety audits typically involve periodic inspections and manual data collection, incurring costs related to labor, equipment, and downtime, which may lead to higher long-term expenses and potential gaps in real-time hazard detection. Digital twin monitoring leverages continuous, real-time data integration and simulation, reducing the need for frequent physical audits and enabling proactive safety management, resulting in lower operational costs and increased efficiency. Investing in a digital twin system can yield significant cost savings by enhancing predictive maintenance, minimizing incidents, and optimizing resource allocation in safety protocols.

Future Trends in Industrial Safety Management

Safety audits traditionally rely on periodic inspections to identify risks, while digital twin monitoring enables continuous, real-time hazard detection through virtual replicas of industrial processes. Future trends in industrial safety management emphasize integrating AI-driven analytics with digital twins to predict and prevent accidents proactively. This convergence of advanced technologies enhances risk assessment accuracy and fosters a culture of proactive safety compliance.

Related Important Terms

Predictive Safety Analytics

Safety audits identify existing hazards through periodic inspections, while digital twin monitoring leverages real-time data and predictive safety analytics to anticipate and prevent potential incidents. By integrating sensor data with advanced algorithms, digital twins enable proactive risk management and continuous improvement in workplace safety.

Real-time Risk Visualization

Safety audits provide periodic evaluations of workplace hazards through scheduled inspections and compliance checks, while digital twin monitoring enables real-time risk visualization by simulating operational conditions and detecting potential safety threats instantly. Leveraging digital twin technology enhances proactive hazard identification and decision-making, reducing response time and improving overall safety management effectiveness.

Digital Audit Trail

Digital Audit Trail in safety management provides a continuous, immutable record of all inspections, incidents, and compliance activities, vastly improving traceability and accountability compared to traditional safety audits. Integrating Digital Twin Monitoring enables real-time visualization and predictive analytics, enhancing proactive risk identification and response without the delays inherent in periodic safety audits.

Virtual Safety Walkthrough

A Safety Audit systematically assesses workplace hazards through physical inspections and documentation review, while Digital Twin Monitoring creates a virtual replica of the facility for continuous, real-time safety analysis. Virtual Safety Walkthroughs enabled by Digital Twin technology allow stakeholders to identify risks and simulate emergency scenarios remotely, enhancing proactive safety management and reducing incident response times.

Continuous Compliance Monitoring

Continuous compliance monitoring in safety audits relies on periodic inspections and manual data analysis, limiting real-time hazard detection and response. Digital twin monitoring enables continuous, dynamic safety oversight by simulating physical assets and processes, allowing instant identification of compliance deviations and predictive risk management.

IoT-enabled Incident Reporting

IoT-enabled incident reporting enhances safety audits by providing real-time data collection and analysis, enabling more accurate identification of hazards and compliance verification. Digital twin monitoring leverages this data to simulate and predict potential safety incidents in virtual environments, facilitating proactive risk management and continuous improvement.

Automated Hazard Detection

Automated hazard detection in safety audits leverages predefined checklists and manual inspections, whereas digital twin monitoring uses real-time sensor data and AI-driven simulations to identify potential risks dynamically. Digital twin technology enhances predictive maintenance and incident prevention, enabling continuous safety oversight beyond traditional audit limitations.

Cyber-physical Safety Twin

A Safety Audit systematically evaluates workplace hazards through manual inspections and compliance checks, while Digital Twin Monitoring employs real-time, data-driven models to simulate and predict safety risks in cyber-physical systems. Cyber-physical Safety Twins integrate sensor data and AI algorithms to continuously monitor, analyze, and optimize safety conditions, enabling proactive risk mitigation and enhanced decision-making in industrial environments.

Remote Safety Assessment

Safety audits provide systematic evaluations of workplace hazards through periodic inspections and compliance checks, while digital twin monitoring enables continuous remote safety assessment by simulating real-time operational conditions using IoT data and advanced analytics. Remote safety assessment with digital twins enhances proactive risk identification and rapid response to safety incidents, minimizing downtime and improving overall safety management efficiency.

Dynamic Control Loop Auditing

Safety audits provide static assessments of workplace hazards, while digital twin monitoring enables continuous, real-time evaluation through dynamic control loop auditing, enhancing the detection of system anomalies and predicting potential safety risks. Integrating digital twin technology with control loop analytics optimizes operational safety by simulating process behavior and enabling proactive interventions before incidents occur.

Safety Audit vs Digital Twin Monitoring Infographic

industrydif.com

industrydif.com