The Bowtie method visually maps hazards to potential consequences and control measures, enhancing safety pet management by identifying and mitigating risks effectively. Unlike traditional hazard analysis, Bowtie provides a clear framework for understanding how hazards can escalate and where safety interventions should be applied. Implementing Bowtie in pet safety ensures proactive prevention of accidents and swift response strategies, reducing the likelihood of harm.

Table of Comparison

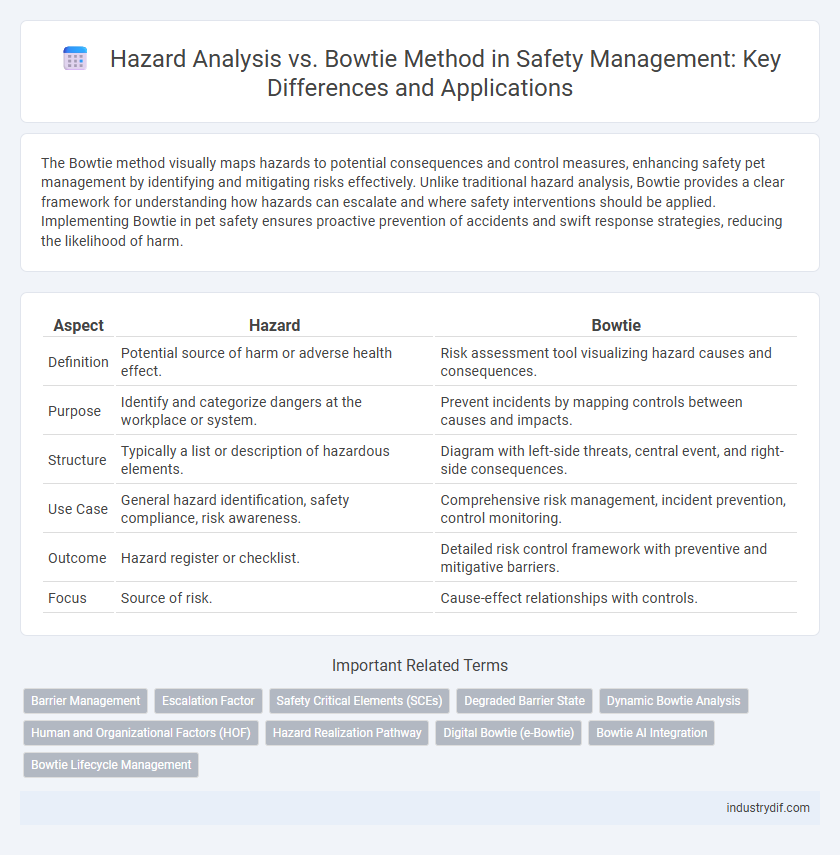

| Aspect | Hazard | Bowtie |

|---|---|---|

| Definition | Potential source of harm or adverse health effect. | Risk assessment tool visualizing hazard causes and consequences. |

| Purpose | Identify and categorize dangers at the workplace or system. | Prevent incidents by mapping controls between causes and impacts. |

| Structure | Typically a list or description of hazardous elements. | Diagram with left-side threats, central event, and right-side consequences. |

| Use Case | General hazard identification, safety compliance, risk awareness. | Comprehensive risk management, incident prevention, control monitoring. |

| Outcome | Hazard register or checklist. | Detailed risk control framework with preventive and mitigative barriers. |

| Focus | Source of risk. | Cause-effect relationships with controls. |

Understanding Hazards: A Safety Industry Overview

Understanding hazards is critical in the safety industry as it involves identifying potential sources of harm, such as chemical spills, machinery malfunctions, or fire risks. Bowtie methodology provides a visual framework that links hazards to preventive barriers and mitigation controls, enabling clear risk analysis and management. This approach enhances hazard awareness by mapping cause-effect relationships and improving safety protocols in industries like oil and gas, construction, and manufacturing.

What is a Bowtie Analysis?

A Bowtie Analysis is a risk assessment method that visually maps out the pathways from potential hazards to their possible consequences, highlighting preventive and mitigating controls. This approach helps organizations understand and manage safety risks by illustrating the relationships between hazards, causes, control measures, and outcomes in a clear, structured format. Bowtie diagrams serve as effective tools for communicating complex safety information and enhancing hazard management strategies across industries.

Key Differences: Hazard Identification vs. Bowtie Methodology

Hazard identification involves systematically recognizing potential sources of harm within a workplace or process, focusing on the root causes of accidents. The Bowtie methodology visually maps the pathways from identified hazards to potential consequences, incorporating preventive and mitigative barriers to manage risk. Key differences lie in hazard identification being a foundational step for risk assessment, while the Bowtie technique integrates this step into a comprehensive risk management framework that highlights control measures.

Advantages of Hazard Assessment in Industrial Settings

Hazard assessment provides a systematic approach to identifying and evaluating potential risks in industrial settings, enabling targeted mitigation strategies that enhance workplace safety. It focuses on direct identification of hazards, which facilitates early detection and prevention of accidents before they escalate. Compared to Bowtie analysis, hazard assessment is often more straightforward and cost-effective, making it suitable for continuous monitoring and compliance with safety regulations.

How Bowtie Diagrams Visualize Risk Management

Bowtie diagrams visualize risk management by clearly mapping out hazard causes, preventative controls, and potential consequences, providing an intuitive overview of safety barriers. This method highlights paths from hazards to outcomes through threat-event controls, enabling organizations to identify risk escalation points and strengthen mitigation strategies. By integrating cause-effect relationships with control measures, Bowtie diagrams enhance hazard identification and foster proactive safety management.

Step-by-Step Process: Conducting a Hazard Analysis

Hazard analysis begins with identifying potential hazards through systematic data collection and observation of workplace processes. The bowtie method enhances this by visually mapping the relationship between hazards, preventive controls, and mitigation measures, facilitating clearer risk communication. Step-by-step, the process involves hazard identification, risk assessment, control measure evaluation, and continuous monitoring to ensure workplace safety.

Implementing Bowtie for Effective Control Measures

Implementing the Bowtie method enhances hazard management by visually mapping risk pathways and control measures, enabling clear identification of preventive and mitigative actions. This structured approach bridges the gap between hazard identification and risk control, facilitating communication and ensuring compliance with safety standards. Bowtie analysis supports proactive decision-making by pinpointing critical control points, reducing incident likelihood and minimizing consequences effectively.

Common Applications: When to Use Hazard or Bowtie Approaches

Hazard analysis is commonly applied in the early stages of risk management to identify and assess potential dangers associated with specific processes or equipment. The Bowtie method excels in visualizing risk pathways and control measures, making it ideal for complex systems with multiple preventive and mitigative barriers. Organizations typically use hazard analysis for initial risk identification, followed by bowtie diagrams to enhance communication and management of identified risks.

Limitations of Hazard Assessment vs. Bowtie Technique

Hazard assessment primarily identifies potential risks and their sources but often lacks a comprehensive view of the interrelationships between causes and consequences. The Bowtie technique visually maps both preventive and mitigative controls, providing a clearer understanding of risk pathways and control effectiveness. However, hazard assessments may overlook complex scenarios and fail to integrate control measures as effectively as the Bowtie method.

Integrating Hazard and Bowtie Methods for Enhanced Safety

Integrating hazard identification with the Bowtie method enhances safety by providing a comprehensive risk assessment framework that visually maps out potential threats, preventive controls, and mitigation measures. This combined approach allows organizations to identify hazards more precisely and implement targeted barriers, reducing the likelihood and impact of accidents. Utilizing Bowtie analysis in hazard management fosters proactive safety strategies and continuous monitoring, leading to improved operational resilience and risk reduction.

Related Important Terms

Barrier Management

Hazard identification forms the foundation of Barrier Management by pinpointing potential risks, while Bowtie analysis visualizes these hazards and their control measures through structured risk pathways. Effective Barrier Management integrates both approaches to monitor, assess, and maintain safety barriers, ensuring proactive mitigation of operational hazards.

Escalation Factor

The escalation factor in hazard analysis quantifies the potential increase in risk severity if initial controls fail, whereas the bowtie method visually maps these escalation pathways alongside preventive and mitigative barriers, enhancing understanding of how escalation factors influence overall safety management. By integrating escalation factors within bowtie diagrams, organizations can identify critical control points and implement targeted interventions to prevent hazard escalation and ensure effective risk control.

Safety Critical Elements (SCEs)

Hazard analysis identifies potential dangers and associated risks, while the Bowtie method visually maps the pathways from hazards to consequences, highlighting preventive and mitigative controls, including Safety Critical Elements (SCEs) that are essential for maintaining system integrity. Effective management of SCEs through Bowtie diagrams ensures focused monitoring and control, reducing the likelihood and impact of hazardous events in safety-critical operations.

Degraded Barrier State

A degraded barrier state in hazard management significantly increases the risk of incident escalation, as compromised safety layers fail to effectively prevent or mitigate hazards. Bowtie analysis visually maps these degraded barriers, enabling targeted interventions to restore controls and maintain operational safety.

Dynamic Bowtie Analysis

Dynamic Bowtie Analysis enhances traditional hazard assessment by visually mapping risk scenarios with real-time data integration, allowing proactive identification and mitigation of evolving threats. It bridges the gap between static hazard identification and active risk management, optimizing safety performance through continuous monitoring and adaptive control measures.

Human and Organizational Factors (HOF)

Hazard identification centers on pinpointing risks that can trigger accidents, while Bowtie analysis visually maps out risk pathways and controls, emphasizing Human and Organizational Factors (HOF) such as communication, training, and decision-making. Integrating HOF into Bowtie frameworks enhances safety by addressing underlying human errors and organizational weaknesses that traditional hazard assessments may overlook.

Hazard Realization Pathway

The Hazard Realization Pathway in safety management identifies the sequence of events from a hazard's presence to its potential incident, enabling targeted interventions. Bowtie methodology visualizes this pathway by linking hazards, preventive controls, and mitigation measures, promoting comprehensive risk assessment and control.

Digital Bowtie (e-Bowtie)

Digital Bowtie (e-Bowtie) enhances hazard management by visually mapping potential risks against preventive and mitigative controls, facilitating real-time monitoring and more effective communication of safety protocols. Unlike traditional hazard analysis, e-Bowtie integrates dynamic data, enabling proactive risk assessment and streamlined compliance in complex industrial environments.

Bowtie AI Integration

Bowtie AI integration enhances hazard management by combining traditional bowtie risk analysis with real-time data analytics and predictive insights, enabling proactive identification and mitigation of safety threats. This fusion of AI-driven monitoring with bowtie visualization improves hazard awareness, control effectiveness, and decision-making precision in complex safety environments.

Bowtie Lifecycle Management

Bowtie Lifecycle Management provides a comprehensive approach to hazard mitigation by visually mapping prevention and recovery controls around a central hazard, enabling continuous monitoring and improvement throughout the system's operational lifespan. This methodology enhances risk management efficiency by integrating control verification, real-time performance data, and incident analysis, surpassing traditional hazard identification methods in dynamic safety environments.

Hazard vs Bowtie Infographic

industrydif.com

industrydif.com