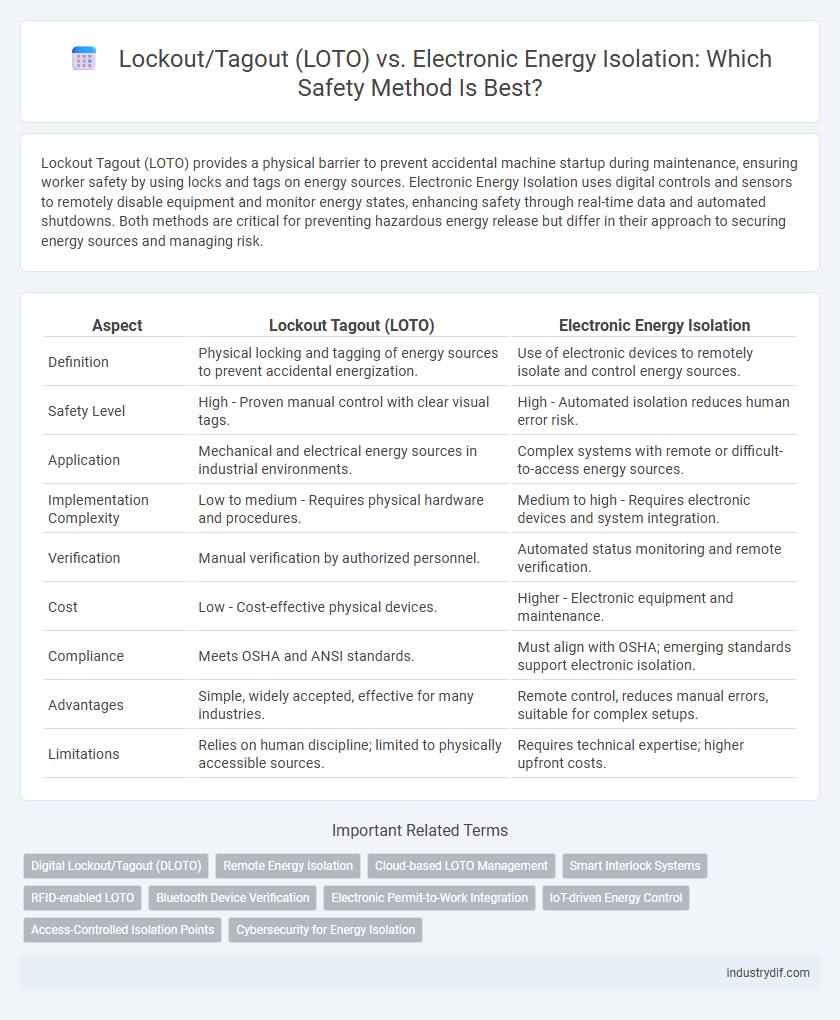

Lockout Tagout (LOTO) provides a physical barrier to prevent accidental machine startup during maintenance, ensuring worker safety by using locks and tags on energy sources. Electronic Energy Isolation uses digital controls and sensors to remotely disable equipment and monitor energy states, enhancing safety through real-time data and automated shutdowns. Both methods are critical for preventing hazardous energy release but differ in their approach to securing energy sources and managing risk.

Table of Comparison

| Aspect | Lockout Tagout (LOTO) | Electronic Energy Isolation |

|---|---|---|

| Definition | Physical locking and tagging of energy sources to prevent accidental energization. | Use of electronic devices to remotely isolate and control energy sources. |

| Safety Level | High - Proven manual control with clear visual tags. | High - Automated isolation reduces human error risk. |

| Application | Mechanical and electrical energy sources in industrial environments. | Complex systems with remote or difficult-to-access energy sources. |

| Implementation Complexity | Low to medium - Requires physical hardware and procedures. | Medium to high - Requires electronic devices and system integration. |

| Verification | Manual verification by authorized personnel. | Automated status monitoring and remote verification. |

| Cost | Low - Cost-effective physical devices. | Higher - Electronic equipment and maintenance. |

| Compliance | Meets OSHA and ANSI standards. | Must align with OSHA; emerging standards support electronic isolation. |

| Advantages | Simple, widely accepted, effective for many industries. | Remote control, reduces manual errors, suitable for complex setups. |

| Limitations | Relies on human discipline; limited to physically accessible sources. | Requires technical expertise; higher upfront costs. |

Introduction to Lockout Tagout (LOTO) and Electronic Energy Isolation

Lockout Tagout (LOTO) is a safety procedure used to ensure machinery is properly shut off and unable to be started up during maintenance or repair, involving physical locks and tags to isolate energy sources. Electronic Energy Isolation utilizes advanced electronic devices to control and monitor energy isolation remotely, enhancing precision and reducing human error. Both methods aim to protect workers from hazardous energy but differ in technology application and operational control.

Defining Lockout Tagout: Processes and Standards

Lockout Tagout (LOTO) is a critical safety procedure designed to prevent accidental machine energization during maintenance by isolating energy sources and applying physical locks and tags. Governed by OSHA standard 29 CFR 1910.147, LOTO requires authorized employees to follow specific steps for energy control, including identifying all sources of hazardous energy and verifying isolation. The process ensures worker protection by enforcing equipment shutdowns, mechanical blocking, and clear communication of energy status before maintenance begins.

Understanding Electronic Energy Isolation Systems

Electronic Energy Isolation Systems provide a modern alternative to traditional Lockout Tagout procedures by using advanced technology to control hazardous energy sources remotely. These systems enhance worker safety by ensuring precise energy cutoff, real-time monitoring, and automated safeguards against accidental re-energization. Integrating electronic isolation reduces human error and improves compliance with OSHA safety standards for energy control.

Key Differences Between LOTO and Electronic Isolation

Lockout Tagout (LOTO) involves physically isolating energy sources using locks and tags to ensure machinery cannot be energized during maintenance, providing a tangible barrier to hazardous energy release. In contrast, Electronic Energy Isolation employs digital controls and sensors to interrupt energy flow, enabling remote monitoring and reducing the risk of human error. Key differences include the reliance on physical devices in LOTO versus software-based systems in electronic isolation, the level of automation, and the potential for real-time status updates in electronic methods.

Advantages and Limitations of Mechanical Lockout Tagout

Mechanical Lockout Tagout (LOTO) provides a tangible, physical barrier that prevents equipment from being energized, ensuring worker safety during maintenance by clearly indicating a locked state. Its advantages include simplicity, low cost, and effectiveness in environments without complex electronic systems. Limitations arise with its dependency on manual application, potential for human error, and inability to control or monitor energy sources remotely as seen in advanced electronic energy isolation systems.

Benefits and Challenges of Electronic Energy Isolation

Electronic Energy Isolation enhances safety by providing real-time monitoring and remote control of hazardous energy sources, reducing human error and enabling faster response during maintenance. It offers seamless integration with automated systems, improving efficiency and compliance with OSHA standards. Challenges include high initial implementation costs, potential cybersecurity risks, and the need for specialized employee training to maximize system effectiveness.

Regulatory Compliance and Industry Guidelines

Lockout Tagout (LOTO) remains the gold standard for regulatory compliance under OSHA standards, specifically 29 CFR 1910.147, mandating the physical isolation and control of hazardous energy sources during maintenance. Electronic Energy Isolation systems complement LOTO by providing real-time digital controls and monitoring, aligning with evolving industry guidelines to enhance worker safety and reduce human error. Integrating electronic solutions with traditional LOTO practices ensures comprehensive adherence to both regulatory requirements and best practice recommendations in high-risk industrial environments.

Safety Risks and Hazard Mitigation Strategies

Lockout Tagout (LOTO) procedures require physical isolation of energy sources to prevent accidental machine startup, mitigating risks of electrocution and mechanical injuries. Electronic Energy Isolation uses advanced control systems with sensors and automated lockout mechanisms to enhance hazard detection and real-time shutdown, reducing human error. Combining both methods improves overall safety by ensuring multiple layers of energy control and hazard mitigation in high-risk environments.

Technology Integration and Future Trends

Lockout Tagout (LOTO) remains a critical safety procedure for isolating hazardous energy, but the integration of Electronic Energy Isolation systems enhances precision and real-time monitoring capabilities. Advanced technologies like IoT sensors and wireless control enable automatic energy shutdowns and remote verification, significantly reducing human error and improving compliance tracking. Future trends indicate increased adoption of AI-driven predictive analytics for proactive hazard identification and the development of interoperable platforms that unify physical lockout methods with electronic safety systems.

Choosing the Right Solution for Your Facility

Choosing the right safety solution depends on the specific energy hazards and operational complexity of your facility. Lockout Tagout (LOTO) provides a physical, robust method to ensure machinery remains de-energized during maintenance, minimizing human error and electrical risks. Electronic Energy Isolation offers advanced monitoring and control capabilities, ideal for facilities seeking real-time status updates and automated safety verification to enhance compliance and reduce downtime.

Related Important Terms

Digital Lockout/Tagout (DLOTO)

Digital Lockout/Tagout (DLOTO) enhances traditional lockout tagout processes by utilizing electronic energy isolation methods, reducing human error and improving real-time monitoring of equipment status. Implementing DLOTO systems increases compliance with OSHA standards and boosts overall workplace safety through automated control and detailed audit trails.

Remote Energy Isolation

Remote energy isolation offers enhanced safety by allowing workers to control hazardous energy sources from a distance, minimizing exposure during lockout tagout (LOTO) procedures. Unlike traditional LOTO, which relies on physical locks and tags, electronic energy isolation integrates automated systems and digital controls to ensure more precise and immediate energy shutdowns.

Cloud-based LOTO Management

Cloud-based Lockout Tagout (LOTO) Management systems enhance safety by providing real-time monitoring, centralized record-keeping, and automated compliance tracking, reducing human error in traditional lockout tagout procedures. Electronic Energy Isolation integrates seamlessly with cloud platforms, enabling remote control, audit trails, and instant notifications, which significantly improve operational safety and regulatory adherence.

Smart Interlock Systems

Smart interlock systems enhance lockout tagout procedures by integrating electronic energy isolation to prevent accidental machine startups during maintenance. These advanced systems use sensors and automated controls to ensure energy sources remain securely isolated, reducing human error and improving overall workplace safety.

RFID-enabled LOTO

RFID-enabled Lockout Tagout (LOTO) systems enhance traditional energy isolation by providing real-time equipment status tracking and automated verification to prevent accidental startup during maintenance. Compared to conventional mechanical lockout methods, electronic energy isolation using RFID technology increases workplace safety by ensuring accurate lock application and immediate alerts for unauthorized removal or operational hazards.

Bluetooth Device Verification

Lockout Tagout procedures ensure worker safety by physically isolating energy sources, but Bluetooth device verification in electronic energy isolation enhances real-time monitoring and remote authorization, reducing human error and improving compliance. This digital method accelerates verification processes and records energy isolation status automatically, offering a more secure and efficient alternative in hazardous environments.

Electronic Permit-to-Work Integration

Electronic Energy Isolation systems significantly enhance Lockout Tagout procedures by integrating electronic permit-to-work platforms, ensuring real-time verification of hazardous energy control and improving worker safety compliance. The seamless digital documentation and automated audit trails reduce human errors and streamline coordination during maintenance operations in high-risk environments.

IoT-driven Energy Control

IoT-driven electronic energy isolation enhances Lockout Tagout (LOTO) by enabling real-time monitoring, remote control, and automated verification of energy sources, significantly reducing human error and increasing workplace safety compliance. This technology integrates smart sensors and connected devices to provide precise energy control, ensuring faster hazard identification and minimizing downtime in industrial environments.

Access-Controlled Isolation Points

Access-controlled isolation points enhance lockout tagout procedures by integrating electronic energy isolation systems, ensuring precise access restrictions and real-time status monitoring to prevent accidental machine energization. This advanced approach reduces human error and increases safety compliance by providing automated control and audit trails for energy isolation in high-risk industrial environments.

Cybersecurity for Energy Isolation

Lockout Tagout (LOTO) procedures physically isolate hazardous energy sources, whereas Electronic Energy Isolation relies on digital controls, introducing potential cybersecurity risks such as unauthorized access or manipulation of energy systems. Implementing robust cybersecurity protocols, including encryption, multi-factor authentication, and network monitoring, is essential to protect electronic energy isolation systems from cyber threats and ensure worker safety.

Lockout Tagout vs Electronic Energy Isolation Infographic

industrydif.com

industrydif.com