Lockout Tagout ensures safety by physically locking and tagging hazardous energy sources to prevent accidental activation during maintenance. Remote Energy Isolation uses wireless or automated systems to control energy sources from a distance, reducing exposure to dangerous environments. Both methods enhance safety protocols but differ in application based on accessibility and risk level.

Table of Comparison

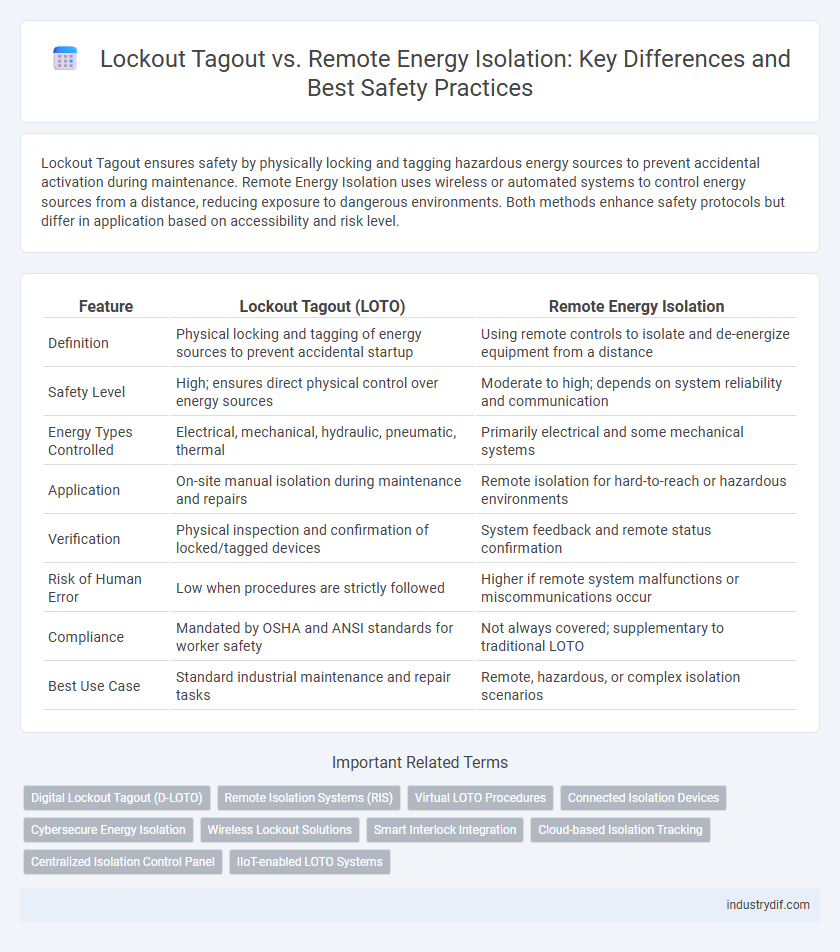

| Feature | Lockout Tagout (LOTO) | Remote Energy Isolation |

|---|---|---|

| Definition | Physical locking and tagging of energy sources to prevent accidental startup | Using remote controls to isolate and de-energize equipment from a distance |

| Safety Level | High; ensures direct physical control over energy sources | Moderate to high; depends on system reliability and communication |

| Energy Types Controlled | Electrical, mechanical, hydraulic, pneumatic, thermal | Primarily electrical and some mechanical systems |

| Application | On-site manual isolation during maintenance and repairs | Remote isolation for hard-to-reach or hazardous environments |

| Verification | Physical inspection and confirmation of locked/tagged devices | System feedback and remote status confirmation |

| Risk of Human Error | Low when procedures are strictly followed | Higher if remote system malfunctions or miscommunications occur |

| Compliance | Mandated by OSHA and ANSI standards for worker safety | Not always covered; supplementary to traditional LOTO |

| Best Use Case | Standard industrial maintenance and repair tasks | Remote, hazardous, or complex isolation scenarios |

Introduction to Lockout Tagout and Remote Energy Isolation

Lockout Tagout (LOTO) is a critical safety procedure designed to prevent accidental machinery startup by physically isolating hazardous energy sources through locks and tags. Remote Energy Isolation (REI) enhances traditional LOTO by enabling operators to disconnect energy sources from a distance, reducing exposure to dangerous environments. Both methods aim to protect workers from electrical, mechanical, hydraulic, and pneumatic hazards during maintenance and servicing activities.

Defining Lockout Tagout (LOTO) Procedures

Lockout Tagout (LOTO) procedures strictly involve physically isolating energy sources by locking and tagging machinery to prevent accidental startup during maintenance. These protocols ensure that equipment remains de-energized, protecting workers from hazardous energy release such as electrical, mechanical, hydraulic, or pneumatic power. Proper LOTO implementation reduces workplace injuries by enforcing controlled isolation and clear identification of locked equipment in compliance with OSHA standards.

Understanding Remote Energy Isolation Technology

Remote energy isolation technology enhances lockout tagout (LOTO) procedures by enabling operators to control hazardous energy sources from a distance, reducing physical exposure and the risk of accidents. This technology integrates sensors, wireless communication, and automated locking devices to ensure that machinery remains de-energized during maintenance. By leveraging real-time status monitoring and remote shutdown capabilities, remote energy isolation improves overall safety compliance and operational efficiency.

Key Differences Between LOTO and Remote Energy Isolation

Lockout Tagout (LOTO) physically secures energy sources with locks and tags to prevent accidental machine startup during maintenance, ensuring worker safety through direct control at the energy isolation point. Remote Energy Isolation utilizes technology to control energy sources from a distance, enhancing flexibility and reducing downtime but requiring robust communication and monitoring systems to ensure effectiveness. The key difference lies in LOTO's reliance on physical locks for energy isolation versus Remote Energy Isolation's dependence on electronic or wireless control mechanisms, impacting implementation methods and safety verification processes.

Compliance and Regulatory Requirements

Lockout Tagout (LOTO) procedures remain the industry standard for compliance with OSHA regulation 29 CFR 1910.147, ensuring effective control of hazardous energy during maintenance. Remote Energy Isolation offers enhanced safety by minimizing worker exposure to energy sources but must still adhere to the same regulatory requirements for energy control procedures. Both methods require documented training and verification processes to meet regulatory audits and maintain workplace safety compliance.

Safety Benefits of Lockout Tagout

Lockout Tagout (LOTO) ensures energy sources are physically locked and tagged, preventing accidental machine energization and significantly reducing workplace injuries. Its strict procedural controls create a clear communication barrier, enhancing worker safety during maintenance by providing visible and tangible evidence of equipment status. Compared to Remote Energy Isolation, LOTO's direct interaction with energy points offers higher reliability in securing hazardous energy sources.

Advantages of Remote Energy Isolation Systems

Remote Energy Isolation systems enhance workplace safety by minimizing the need for personnel to access hazardous energy sources directly, reducing the risk of injury. These systems enable centralized control of energy isolation, improving efficiency and ensuring consistent compliance with lockout/tagout procedures. Integration with digital monitoring allows real-time status updates, further strengthening safety management and incident prevention.

Challenges and Limitations of Each Method

Lockout Tagout (LOTO) faces challenges such as the risk of human error during manual lock placement and limited effectiveness in complex systems with multiple energy sources. Remote Energy Isolation offers improved control and reduced direct exposure but can be limited by technological failures, communication issues, and the need for specialized training. Both methods require rigorous procedures and ongoing maintenance to ensure worker safety and prevent accidental energy release.

Industry Applications and Use Cases

Lockout Tagout (LOTO) remains essential in industrial environments such as manufacturing and maintenance for physically securing energy sources to prevent accidental machine startup. Remote Energy Isolation (REI) is increasingly adopted in hazardous or hard-to-access areas like chemical plants and offshore platforms, enabling workers to isolate energy sources from a safe distance and reduce exposure to danger. Selecting between LOTO and REI depends on specific industry needs, with LOTO preferred for straightforward machinery shutdowns and REI favored for complex, high-risk settings requiring enhanced safety controls.

Best Practices for Choosing the Right Isolation Method

Selecting the appropriate isolation method between Lockout Tagout (LOTO) and Remote Energy Isolation depends on assessing the specific hazards, equipment type, and operational environment. LOTO is best suited for direct, physical control of energy sources, ensuring visible tags and locks prevent accidental energization, while Remote Energy Isolation offers enhanced safety by allowing control from a distance, minimizing worker exposure to hazardous areas. Evaluating factors such as energy types involved, ease of access, and regulatory compliance ensures optimal protection and adherence to safety standards.

Related Important Terms

Digital Lockout Tagout (D-LOTO)

Digital Lockout Tagout (D-LOTO) enhances traditional Lockout Tagout procedures by integrating remote energy isolation technologies, enabling real-time monitoring and control of hazardous energy sources through secure digital platforms. This innovative approach reduces human error, improves compliance tracking, and accelerates safe maintenance workflows by providing instant access to lockout status and documentation.

Remote Isolation Systems (RIS)

Remote Isolation Systems (RIS) enhance workplace safety by allowing energy sources to be controlled and isolated from a distance, reducing the risk of accidental startups during maintenance. Unlike traditional Lockout Tagout procedures, RIS provide real-time verification and centralized control, improving compliance and minimizing human error in hazardous energy management.

Virtual LOTO Procedures

Virtual Lockout Tagout (LOTO) procedures enhance safety by allowing remote energy isolation and control through digital systems, reducing the risk of physical contact with hazardous equipment. Implementing virtual LOTO minimizes human error, streamlines compliance with OSHA standards, and improves efficiency in managing energy control during maintenance tasks.

Connected Isolation Devices

Connected isolation devices enhance Lockout Tagout (LOTO) procedures by enabling remote energy isolation, significantly reducing exposure to hazardous energy sources and increasing worker safety through real-time monitoring and control. These devices integrate IoT technology to provide precise, auditable isolation status, minimizing human error and ensuring compliance with safety regulations.

Cybersecure Energy Isolation

Cybersecure energy isolation enhances lockout tagout procedures by integrating remote control systems that prevent unauthorized access and cyber threats, ensuring safe de-energization of equipment. This method minimizes human error and enables real-time monitoring while maintaining compliance with OSHA lockout tagout standards.

Wireless Lockout Solutions

Wireless lockout solutions enhance Remote Energy Isolation by enabling secure, real-time control of machinery shutdowns without physical presence, reducing exposure to hazardous energy during maintenance. These advanced systems integrate IoT technology and digital tagging to improve safety compliance and operational efficiency in industrial lockout tagout procedures.

Smart Interlock Integration

Smart interlock integration enhances Lockout Tagout (LOTO) procedures by enabling real-time remote energy isolation, reducing human error and increasing operational safety for maintenance personnel. This technology ensures secure access control, automatic system shutdowns, and continuous monitoring, surpassing traditional LOTO methods in preventing accidental energization.

Cloud-based Isolation Tracking

Cloud-based isolation tracking enhances Lockout Tagout (LOTO) and Remote Energy Isolation by providing real-time monitoring, centralized data management, and improved compliance documentation. This technology minimizes human error, accelerates isolation verification, and supports remote audits to ensure workplace safety in complex energy systems.

Centralized Isolation Control Panel

Centralized Isolation Control Panels enhance Lockout Tagout procedures by providing a single point for energy isolation, reducing the risk of accidental re-energization and improving worker safety. Remote Energy Isolation offers the advantage of controlling hazardous energy sources from a safe distance, minimizing exposure and streamlining energy management in complex industrial environments.

IIoT-enabled LOTO Systems

IIoT-enabled Lockout Tagout (LOTO) systems integrate smart sensors and real-time data analytics to enhance remote energy isolation, reducing human error and increasing operational safety in industrial environments. These advanced LOTO solutions enable precise monitoring and control of hazardous energy sources, minimizing downtime and improving compliance with safety regulations.

Lockout Tagout vs Remote Energy Isolation Infographic

industrydif.com

industrydif.com