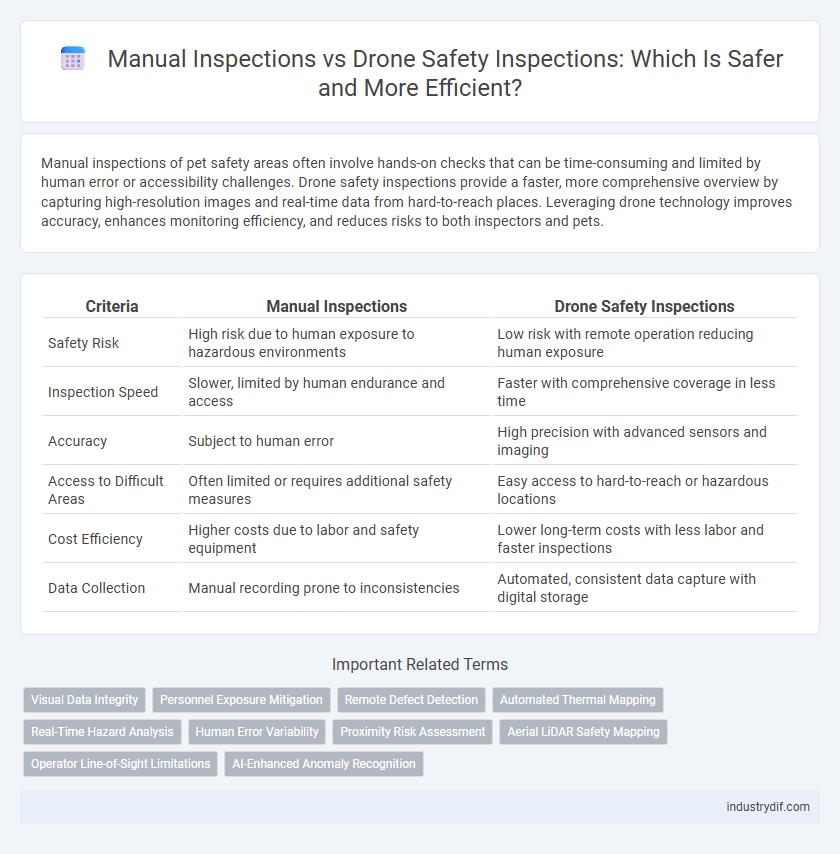

Manual inspections of pet safety areas often involve hands-on checks that can be time-consuming and limited by human error or accessibility challenges. Drone safety inspections provide a faster, more comprehensive overview by capturing high-resolution images and real-time data from hard-to-reach places. Leveraging drone technology improves accuracy, enhances monitoring efficiency, and reduces risks to both inspectors and pets.

Table of Comparison

| Criteria | Manual Inspections | Drone Safety Inspections |

|---|---|---|

| Safety Risk | High risk due to human exposure to hazardous environments | Low risk with remote operation reducing human exposure |

| Inspection Speed | Slower, limited by human endurance and access | Faster with comprehensive coverage in less time |

| Accuracy | Subject to human error | High precision with advanced sensors and imaging |

| Access to Difficult Areas | Often limited or requires additional safety measures | Easy access to hard-to-reach or hazardous locations |

| Cost Efficiency | Higher costs due to labor and safety equipment | Lower long-term costs with less labor and faster inspections |

| Data Collection | Manual recording prone to inconsistencies | Automated, consistent data capture with digital storage |

Introduction to Safety Inspections in Industry

Safety inspections in industry play a crucial role in preventing accidents and ensuring compliance with regulations. Manual inspections require trained personnel to physically examine equipment and infrastructure, often exposing workers to hazardous conditions. Drone safety inspections enhance hazard detection by accessing hard-to-reach areas quickly while minimizing human exposure to dangerous environments.

Overview of Manual Safety Inspection Methods

Manual safety inspection methods rely heavily on trained personnel conducting visual assessments, physical measurements, and functional testing to identify hazards and ensure compliance with safety regulations. These inspections often require workers to navigate challenging environments, increasing the risk of accidents due to human error, fatigue, or limited accessibility. Despite such risks, manual inspections provide detailed condition assessments and immediate corrective action capabilities that remain critical for comprehensive safety management.

Advantages of Manual Inspections

Manual inspections provide direct human observation, allowing inspectors to identify subtle issues that may be missed by drone sensors or cameras, such as texture changes, odors, or minor structural anomalies. They enable tactile assessment and immediate judgment calls, ensuring detailed evaluations in complex environments where drones may have limited access or visibility. Furthermore, manual inspections eliminate risks related to drone malfunctions or regulatory restrictions, ensuring consistent safety compliance in sensitive or crowded industrial sites.

Limitations and Risks of Manual Inspections

Manual inspections often expose workers to hazardous environments, increasing the risk of accidents and injuries, especially in confined spaces or at great heights. Limited visibility and physical accessibility can lead to incomplete assessments and overlooked safety hazards, compromising overall inspection quality. Human error and fatigue further reduce the reliability of manual inspections, making them less effective in identifying potential safety risks compared to drone technology.

Emergence of Drone Safety Inspections

The emergence of drone safety inspections revolutionizes traditional manual inspections by offering enhanced access to hazardous or hard-to-reach areas, significantly reducing risks to human inspectors. Equipped with high-resolution cameras and sensors, drones provide real-time data and precise visual documentation, improving hazard identification and response times. This technological advancement supports comprehensive safety compliance while optimizing operational efficiency in industrial, construction, and infrastructure environments.

Key Benefits of Drone-Based Safety Inspections

Drone-based safety inspections significantly reduce the risk of worker injuries by eliminating the need for personnel to access hazardous or hard-to-reach areas. These inspections offer faster data collection with high-resolution imaging and real-time analysis, improving accuracy and enabling prompt identification of safety hazards. The technology also lowers operational costs by minimizing downtime and reducing reliance on scaffolding or heavy equipment.

Comparing Accuracy: Manual vs. Drone Inspections

Drone safety inspections offer superior accuracy by utilizing high-resolution cameras and sensors that capture detailed images and data inaccessible to the human eye during manual inspections. Manual inspections rely heavily on subjective human judgment, which can lead to inconsistent results and missed hazards, especially in hard-to-reach or hazardous areas. Advanced drones equipped with AI-powered analytics enhance precision by detecting anomalies and documenting conditions in real-time, reducing the likelihood of human error.

Cost-Efficiency Analysis: Manual vs. Drone Methods

Manual inspections often incur higher labor costs due to the need for specialized personnel, extended timeframes, and potential safety hazards requiring additional precautions. Drone safety inspections significantly reduce operational expenses by minimizing human involvement, accelerating data collection, and decreasing the likelihood of accidents or downtime. Cost-efficiency analysis consistently favors drone methods for industries like construction, energy, and infrastructure maintenance, where frequent and precise safety assessments are crucial.

Regulatory and Safety Compliance for Drone Inspections

Drone safety inspections align with regulatory frameworks such as FAA Part 107, ensuring operators are certified and flights adhere to airspace restrictions. Manual inspections, while traditional, may expose workers to higher risks of falls or accidents in hazardous environments. Leveraging drone technology enhances compliance by minimizing human exposure and providing precise documentation for regulatory reporting.

Future Trends in Industrial Safety Inspections

Future trends in industrial safety inspections emphasize the integration of drone technology to enhance efficiency, accuracy, and worker safety. Drones equipped with high-resolution cameras and sensors enable real-time data collection in hazardous environments, reducing the need for manual inspections that expose personnel to risks. The adoption of AI-powered analytics further refines drone inspection data, facilitating predictive maintenance and proactive safety interventions.

Related Important Terms

Visual Data Integrity

Manual inspections often suffer from inconsistent visual data integrity due to human error and limited access to hard-to-reach areas. Drone safety inspections enhance visual data accuracy by capturing high-resolution images and videos with consistent coverage, enabling precise analysis and reducing inspection risks.

Personnel Exposure Mitigation

Manual inspections expose personnel to risks such as falls, hazardous environments, and fatigue, increasing the likelihood of accidents and injuries. Drone safety inspections mitigate personnel exposure by remotely accessing difficult or dangerous areas, significantly reducing the need for physical presence and enhancing overall workplace safety.

Remote Defect Detection

Manual inspections often expose workers to hazardous environments and limit detection capabilities to visible or easily accessible defects, reducing overall safety and efficiency. Drone safety inspections enhance remote defect detection by providing high-resolution imaging and thermal sensing from hard-to-reach areas, minimizing human risk while increasing accuracy and coverage.

Automated Thermal Mapping

Automated thermal mapping during drone safety inspections enhances hazard detection by capturing precise thermal data across large areas quickly, reducing human error and exposure to dangerous environments. Manual inspections lack the efficiency and accuracy of drones equipped with thermal sensors, often resulting in slower identification of potential safety risks in industrial settings.

Real-Time Hazard Analysis

Manual inspections often rely on limited visual perspectives and pose risks to inspectors in hazardous environments, whereas drone safety inspections enable real-time hazard analysis through high-resolution sensors and live data transmission, enhancing accuracy and worker safety. Utilizing drones for inspections reduces human exposure to dangerous sites and allows for immediate identification and assessment of potential safety threats.

Human Error Variability

Manual inspections in safety protocols are prone to human error variability due to fatigue, inconsistent judgment, and limited accessibility in hazardous environments. Drone safety inspections offer standardized data collection with reduced human bias, improving accuracy and reliability in identifying potential risks.

Proximity Risk Assessment

Manual inspections pose higher proximity risks to inspectors due to close physical interaction with hazardous environments, increasing chances of injury or exposure. Drone safety inspections significantly reduce these risks by enabling remote assessment of dangerous areas, enhancing worker safety and minimizing human error during proximity risk evaluations.

Aerial LiDAR Safety Mapping

Aerial LiDAR safety mapping using drones significantly reduces risks associated with manual inspections by capturing high-resolution topographic data from hazardous or hard-to-reach areas without exposing personnel to danger. This technology enhances precision in identifying safety hazards, accelerates data collection, and minimizes human error, thereby optimizing overall site safety management.

Operator Line-of-Sight Limitations

Manual inspections require operators to maintain direct line-of-sight to ensure safety, often limiting access to hazardous or hard-to-reach areas, which increases risk. Drone safety inspections overcome these limitations by enabling remote visual assessments beyond operator line-of-sight, enhancing hazard detection and reducing exposure to dangerous environments.

AI-Enhanced Anomaly Recognition

AI-enhanced anomaly recognition in drone safety inspections significantly improves detection accuracy and speed compared to manual inspections, reducing human error and enhancing risk assessment in hazardous environments. Machine learning algorithms analyze high-resolution drone imagery to identify potential safety issues such as structural defects, corrosion, and equipment malfunctions more consistently and comprehensively than traditional manual methods.

Manual Inspections vs Drone Safety Inspections Infographic

industrydif.com

industrydif.com