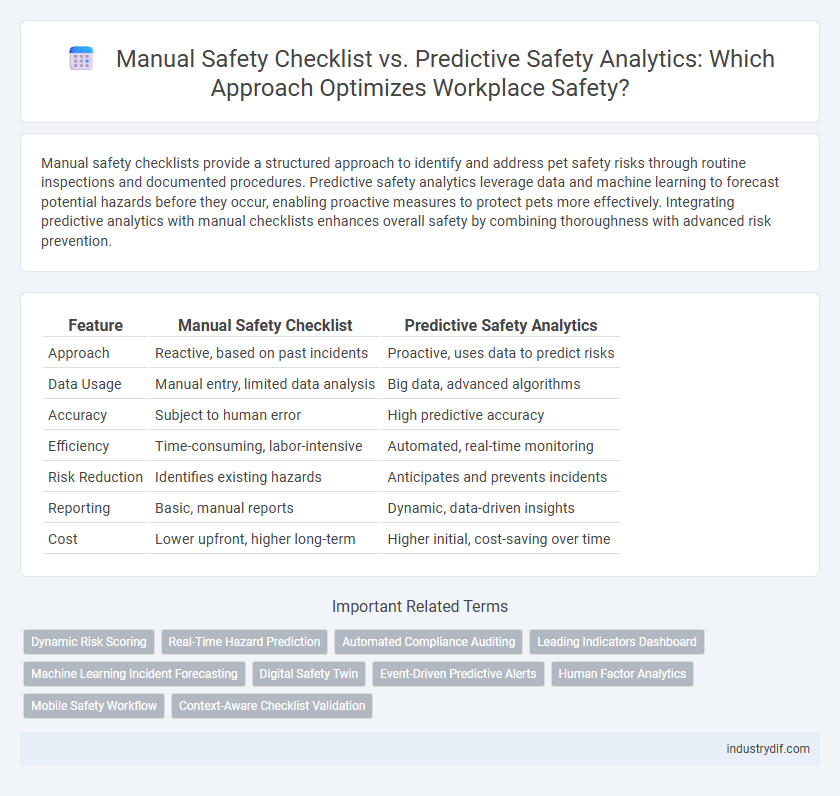

Manual safety checklists provide a structured approach to identify and address pet safety risks through routine inspections and documented procedures. Predictive safety analytics leverage data and machine learning to forecast potential hazards before they occur, enabling proactive measures to protect pets more effectively. Integrating predictive analytics with manual checklists enhances overall safety by combining thoroughness with advanced risk prevention.

Table of Comparison

| Feature | Manual Safety Checklist | Predictive Safety Analytics |

|---|---|---|

| Approach | Reactive, based on past incidents | Proactive, uses data to predict risks |

| Data Usage | Manual entry, limited data analysis | Big data, advanced algorithms |

| Accuracy | Subject to human error | High predictive accuracy |

| Efficiency | Time-consuming, labor-intensive | Automated, real-time monitoring |

| Risk Reduction | Identifies existing hazards | Anticipates and prevents incidents |

| Reporting | Basic, manual reports | Dynamic, data-driven insights |

| Cost | Lower upfront, higher long-term | Higher initial, cost-saving over time |

Defining Manual Safety Checklists

Manual safety checklists consist of predefined inspection items used to ensure compliance with safety protocols during routine operations. These checklists provide a structured approach for workers to identify hazards, document safety conditions, and verify the completion of safety measures. While effective for standard safety verification, they rely heavily on human accuracy and may lack the ability to predict emerging risks.

Understanding Predictive Safety Analytics

Predictive Safety Analytics leverages historical data and machine learning algorithms to identify potential hazards before incidents occur, enhancing proactive risk management. Unlike manual safety checklists that rely on human observation and routine, predictive analytics continuously processes vast datasets to detect patterns and anomalies in real time. This advanced approach improves accuracy in safety predictions, enabling organizations to implement targeted interventions and reduce workplace accidents effectively.

Key Differences Between Manual and Predictive Approaches

Manual safety checklists rely on human inspection and predetermined criteria to identify hazards, often leading to reactive measures based on past incidents. Predictive safety analytics uses data-driven algorithms and machine learning to forecast potential risks, enabling proactive interventions before incidents occur. The key difference lies in manual methods being static and retrospective, while predictive approaches are dynamic, real-time, and focused on preventing future safety issues.

Pros and Cons of Manual Safety Checklists

Manual safety checklists provide a straightforward, low-cost method for identifying workplace hazards and ensuring compliance with safety protocols, making them accessible for organizations with limited resources. However, they rely heavily on human accuracy and timely execution, which can lead to incomplete or inconsistent assessments, increasing the potential for overlooked risks. Unlike predictive safety analytics, manual checklists lack real-time data integration and fail to proactively anticipate safety issues based on historical trends and patterns.

Advantages of Predictive Safety Analytics

Predictive Safety Analytics leverages real-time data and advanced algorithms to identify potential hazards before incidents occur, significantly reducing workplace accidents and improving overall safety performance. Unlike manual safety checklists that rely on periodic inspections and human judgment, predictive analytics continuously monitors patterns and trends, enabling proactive risk management and quicker responses to emerging threats. This data-driven approach enhances decision-making accuracy and optimizes resource allocation for safety interventions.

Impact on Workplace Safety Culture

Manual safety checklists foster a structured approach to hazard identification, reinforcing routine compliance and employee accountability within workplace safety culture. Predictive safety analytics leverage real-time data and machine learning algorithms to identify potential risks proactively, driving a shift from reactive to preventive safety measures. Integrating predictive analytics enhances safety culture by promoting continuous improvement, informed decision-making, and a data-driven mindset across all organizational levels.

Data Collection Methods: Manual vs. Predictive Systems

Manual safety checklist data collection depends on human observations and periodic inspections, often resulting in incomplete or delayed reporting of safety issues. Predictive safety analytics leverage continuous sensor data and real-time monitoring to provide comprehensive and timely insights into potential hazards. The automated nature of predictive systems enhances accuracy and enables proactive risk mitigation compared to manual methods.

Integration Challenges and Best Practices

Manual safety checklists often face challenges in integration due to their reliance on static data and human input, leading to inconsistencies and delayed hazard identification. Predictive safety analytics require seamless integration with real-time data sources and advanced algorithms, which can be complex but enhance proactive risk management. Best practices involve combining manual checklist insights with predictive analytics through interoperability frameworks and continuous data validation to create a comprehensive safety system.

Real-world Case Studies: Checklist vs. Analytics

Manual safety checklists have long served as essential tools in industries like construction and manufacturing, systematically guiding inspections to prevent accidents through regular hazard identification. Predictive safety analytics enhance these efforts by utilizing real-time data from sensors, historical incident reports, and environmental factors to forecast and mitigate risks proactively, as demonstrated in case studies from oil refineries and transportation sectors. Companies integrating predictive analytics report significant reductions in workplace injuries and improved compliance compared to reliance on manual checklists alone.

The Future of Safety: Hybrid Safety Management Solutions

Hybrid safety management solutions integrate Manual Safety Checklists with Predictive Safety Analytics to enhance workplace hazard identification and risk mitigation. Combining real-time data analysis from predictive models with the thoroughness of manual inspections enables proactive safety interventions and continuous improvement. This approach maximizes safety performance by leveraging both human judgment and advanced technology for comprehensive risk management.

Related Important Terms

Dynamic Risk Scoring

Dynamic Risk Scoring leverages Predictive Safety Analytics to continuously assess real-time data, identifying emerging hazards more effectively than static Manual Safety Checklists. This advanced approach enhances risk mitigation by providing actionable insights, improving workplace safety outcomes through proactive intervention.

Real-Time Hazard Prediction

Manual safety checklists rely on scheduled inspections and subjective assessments, often resulting in delayed identification of hazards. Predictive safety analytics leverage real-time data and machine learning algorithms to proactively detect and predict potential safety risks, enabling immediate intervention and reducing workplace incidents.

Automated Compliance Auditing

Predictive safety analytics enhances automated compliance auditing by continuously monitoring real-time data to identify potential hazards and non-compliance issues faster than manual safety checklists. This automated approach reduces human error, improves accuracy, and ensures adherence to safety regulations with greater efficiency.

Leading Indicators Dashboard

Manual safety checklists provide a traditional method for identifying hazards through direct observations and employee feedback, yet they often lack real-time data integration and predictive capability. Predictive safety analytics leverage a Leading Indicators Dashboard to monitor critical metrics such as near-miss reports, equipment condition, and behavioral trends, enabling proactive risk mitigation and improving overall workplace safety outcomes.

Machine Learning Incident Forecasting

Manual safety checklists rely on static, human-reviewed data that can overlook subtle risk patterns, whereas predictive safety analytics leverage machine learning algorithms to analyze historical incident data and forecast potential hazards with higher accuracy. Machine learning incident forecasting enhances workplace safety by identifying emerging risks in real-time, enabling proactive interventions that reduce accidents and improve compliance.

Digital Safety Twin

Manual safety checklists provide static, time-bound assessments prone to human error, while predictive safety analytics leverage Digital Safety Twins to create dynamic, real-time simulations of operational environments, enabling proactive hazard identification and risk mitigation. Utilizing Digital Safety Twins enhances safety management by continuously integrating sensor data and machine learning models to predict incidents before they occur.

Event-Driven Predictive Alerts

Event-driven predictive alerts leverage real-time data and machine learning algorithms to identify hazardous conditions before incidents occur, enhancing proactive safety measures beyond the reactive nature of manual safety checklists. This predictive approach significantly reduces workplace accidents by providing timely, actionable insights that manual inspections cannot match.

Human Factor Analytics

Manual Safety Checklists rely on human observation and judgment, often leading to inconsistent data and overlooked risks, whereas Predictive Safety Analytics leverage Human Factor Analytics to identify behavioral patterns and predict potential hazards before incidents occur. Integrating biometric data, fatigue levels, and real-time monitoring enhances proactive risk management and reduces human error in high-stakes environments.

Mobile Safety Workflow

Manual safety checklists rely on static, user-driven inspections that often miss real-time hazards, whereas predictive safety analytics leverage mobile safety workflows to continuously analyze sensor data and worker inputs, enabling proactive risk mitigation. Integrating mobile safety workflows with predictive analytics enhances hazard detection accuracy and accelerates decision-making, significantly reducing incident rates and improving overall workplace safety.

Context-Aware Checklist Validation

Manual safety checklists rely on predetermined steps that may lack adaptability to dynamic work environments, leading to potential oversights in hazard identification. Predictive safety analytics enhance context-aware checklist validation by utilizing real-time data and machine learning algorithms to anticipate risks and tailor safety protocols specific to changing operational conditions.

Manual Safety Checklist vs Predictive Safety Analytics Infographic

industrydif.com

industrydif.com