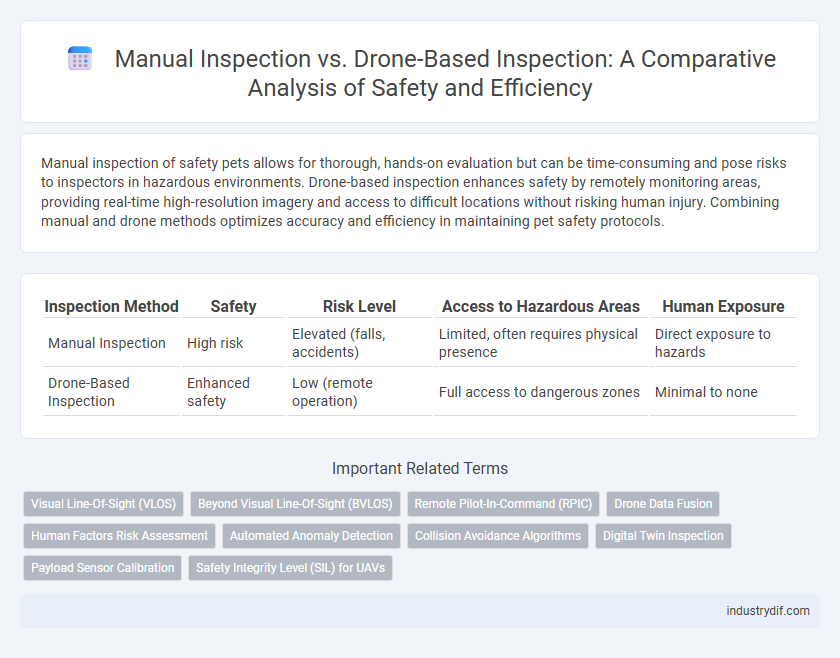

Manual inspection of safety pets allows for thorough, hands-on evaluation but can be time-consuming and pose risks to inspectors in hazardous environments. Drone-based inspection enhances safety by remotely monitoring areas, providing real-time high-resolution imagery and access to difficult locations without risking human injury. Combining manual and drone methods optimizes accuracy and efficiency in maintaining pet safety protocols.

Table of Comparison

| Inspection Method | Safety | Risk Level | Access to Hazardous Areas | Human Exposure |

|---|---|---|---|---|

| Manual Inspection | High risk | Elevated (falls, accidents) | Limited, often requires physical presence | Direct exposure to hazards |

| Drone-Based Inspection | Enhanced safety | Low (remote operation) | Full access to dangerous zones | Minimal to none |

Introduction to Inspection Methods in Safety-Critical Industries

Manual inspection in safety-critical industries relies on human expertise to identify hazards, ensuring compliance with strict regulatory standards through direct visual and physical assessment. Drone-based inspection leverages advanced imaging technologies and remote operation to enhance safety by accessing hard-to-reach areas while reducing human exposure to dangerous environments. Both methods prioritize accuracy and reliability, but drones offer improved efficiency and risk mitigation in hazardous inspection scenarios.

Defining Manual Inspection: Processes and Limitations

Manual inspection involves human inspectors physically examining infrastructure, equipment, or facilities to identify defects, wear, or safety hazards through direct observation and tactile assessment. This process can be time-consuming, subject to human error, and limited by accessibility challenges, especially in hazardous or hard-to-reach areas. Constraints such as fatigue, inconsistencies in judgment, and restricted inspection frequency reduce overall effectiveness in maintaining safety standards.

Drone-Based Inspection: Technology Overview

Drone-based inspection leverages advanced sensors, high-resolution cameras, and AI-powered analytics to enhance safety by detecting hazards in hard-to-reach areas without risking human exposure. Real-time data transmission and automated flight paths enable precise monitoring of infrastructure, minimizing inspection time and human error. This technology significantly improves hazard identification accuracy and operational safety compared to traditional manual inspections.

Safety Risks of Manual Inspection

Manual inspection exposes workers to significant safety risks, including falls from heights, exposure to hazardous environments, and repetitive strain injuries. Human inspectors often face unpredictable conditions such as unstable structures and toxic substances, which increase the likelihood of accidents. In contrast, these risks highlight the urgent need for safer alternatives like drone-based inspection technologies.

Enhanced Safety Protocols with Drone-Based Inspection

Drone-based inspection enhances safety protocols by minimizing human exposure to hazardous environments such as high altitudes, confined spaces, and unstable structures. Equipped with high-resolution cameras and thermal sensors, drones provide real-time data without risking personnel injury. This technology reduces the likelihood of accidents during inspections and ensures consistent monitoring of potentially dangerous sites.

Human Error in Manual Inspections vs. Automated Drone Accuracy

Manual inspections are prone to human error, with factors such as fatigue, distraction, and inconsistent judgment leading to missed hazards and inaccurate assessments. Drone-based inspections leverage automated technologies like AI-powered imaging and GPS navigation to achieve higher accuracy and consistent data collection, reducing risks associated with human factors. This increased precision significantly enhances workplace safety by identifying potential issues earlier and more reliably than traditional manual methods.

Regulatory Compliance: Manual vs. Drone Operations

Manual inspections adhere to established safety protocols and regulatory standards set by occupational health agencies, ensuring human inspectors operate within controlled environments to minimize risks. Drone-based inspections comply with aviation regulations such as FAA Part 107, requiring certified operators and adherence to no-fly zones, altitude limits, and privacy laws to ensure safe and legal operation. Both methods demand rigorous documentation and reporting to maintain compliance with industry-specific safety regulations and mitigate liability.

Cost and Time Efficiency Impacts on Workplace Safety

Manual inspection often involves higher labor costs and longer timeframes, increasing exposure to workplace hazards and fatigue-related errors. Drone-based inspection significantly reduces inspection time and operational costs, enabling rapid identification of safety risks without putting workers in dangerous environments. Implementing drone technology enhances overall workplace safety by minimizing human exposure to hazardous conditions while maintaining cost-effective inspection schedules.

Case Studies: Incident Rates in Manual vs. Drone Inspections

Case studies show that incident rates in manual inspections are significantly higher due to human error, limited accessibility, and fatigue during repetitive tasks. Drone-based inspections enhance safety by reducing worker exposure to hazardous environments and enabling detailed data capture from hard-to-reach areas. Statistical analysis reveals a 40-60% decrease in safety incidents when drones are utilized for routine infrastructure assessments and maintenance inspections.

Future Trends: Innovations in Inspection Safety Methods

Future trends in inspection safety methods emphasize the integration of advanced drone technology equipped with AI-powered sensors, enhancing hazard detection and reducing human exposure to dangerous environments. Manual inspection will increasingly incorporate augmented reality (AR) tools to improve precision and real-time safety data visualization, minimizing errors and accidents. Combining drone-based systems with IoT connectivity enables predictive maintenance models that further boost workplace safety and operational efficiency.

Related Important Terms

Visual Line-Of-Sight (VLOS)

Manual inspection ensures safety through direct human observation within Visual Line-Of-Sight (VLOS), minimizing the risk of undetected hazards. Drone-based inspection expands coverage capabilities while maintaining VLOS requirements, offering enhanced risk management and real-time data collection for safer operations.

Beyond Visual Line-Of-Sight (BVLOS)

Manual inspection beyond visual line-of-sight (BVLOS) poses significant safety risks due to limited visibility and increased human error potential. Drone-based BVLOS inspections enhance safety by providing real-time data from hazardous or hard-to-reach locations, minimizing worker exposure and improving situational awareness.

Remote Pilot-In-Command (RPIC)

Remote Pilot-In-Command (RPIC) plays a critical role in drone-based inspections by ensuring precise control and adherence to safety protocols, significantly reducing human exposure to hazardous environments compared to manual inspection methods. The RPIC's expertise in flight operations and real-time decision-making enhances operational safety, minimizes risks, and improves the accuracy of inspection data.

Drone Data Fusion

Drone data fusion integrates multisensor inputs such as LiDAR, thermal imaging, and high-resolution cameras to enhance the accuracy and reliability of safety inspections compared to manual methods. This fusion technology enables real-time hazard detection and comprehensive site analysis, significantly reducing human error and improving overall risk assessment.

Human Factors Risk Assessment

Manual inspection exposes workers to higher risks such as falls, fatigue, and human error, significantly increasing the likelihood of accidents during safety assessments. Drone-based inspection mitigates these human factors by reducing physical hazards and enabling remote data collection, enhancing overall safety and accuracy in risk evaluations.

Automated Anomaly Detection

Automated anomaly detection in drone-based inspection significantly enhances safety by identifying potential hazards with higher precision and speed compared to manual inspections, which are prone to human error and fatigue. Advanced AI algorithms process real-time data captured by drones, enabling early detection of structural defects and environmental risks that manual inspections may overlook.

Collision Avoidance Algorithms

Collision avoidance algorithms in drone-based inspections leverage real-time sensor data and advanced AI to detect and navigate around obstacles, significantly reducing the risk of accidents compared to manual inspections. Manual inspections rely heavily on human vigilance and experience, which can lead to higher chances of overlooked hazards and collision incidents.

Digital Twin Inspection

Digital Twin Inspection integrates real-time drone data with manual inspection inputs to create highly accurate digital replicas, enhancing hazard identification and predictive maintenance. This approach reduces human exposure to dangerous environments by enabling remote, efficient analysis of structural integrity and safety compliance.

Payload Sensor Calibration

Manual inspection of payload sensor calibration often risks human error and inconsistent data, leading to compromised safety standards. Drone-based inspection ensures precise sensor calibration through automated, repeatable measurements, enhancing accuracy and reducing hazards associated with manual handling.

Safety Integrity Level (SIL) for UAVs

Drone-based inspections enhance Safety Integrity Level (SIL) by minimizing human exposure to hazardous environments and enabling precise risk assessment through real-time data analytics. Unlike manual inspection, UAVs maintain consistent safety protocols via automated flight control systems, significantly reducing the probability of accidents and ensuring higher compliance with SIL standards.

Manual Inspection vs Drone-Based Inspection Infographic

industrydif.com

industrydif.com