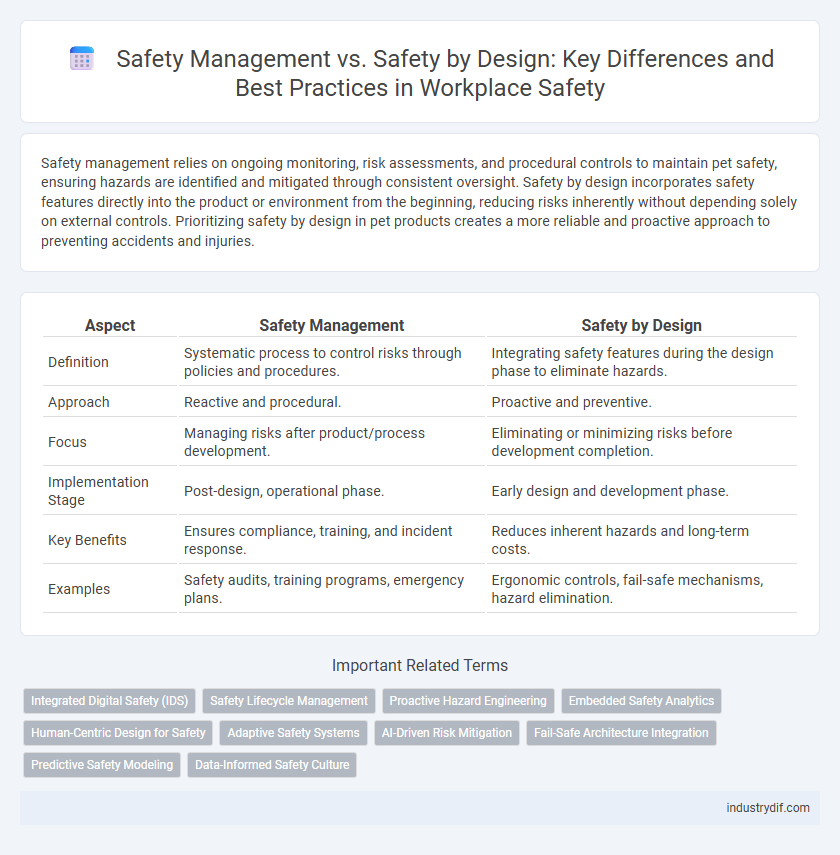

Safety management relies on ongoing monitoring, risk assessments, and procedural controls to maintain pet safety, ensuring hazards are identified and mitigated through consistent oversight. Safety by design incorporates safety features directly into the product or environment from the beginning, reducing risks inherently without depending solely on external controls. Prioritizing safety by design in pet products creates a more reliable and proactive approach to preventing accidents and injuries.

Table of Comparison

| Aspect | Safety Management | Safety by Design |

|---|---|---|

| Definition | Systematic process to control risks through policies and procedures. | Integrating safety features during the design phase to eliminate hazards. |

| Approach | Reactive and procedural. | Proactive and preventive. |

| Focus | Managing risks after product/process development. | Eliminating or minimizing risks before development completion. |

| Implementation Stage | Post-design, operational phase. | Early design and development phase. |

| Key Benefits | Ensures compliance, training, and incident response. | Reduces inherent hazards and long-term costs. |

| Examples | Safety audits, training programs, emergency plans. | Ergonomic controls, fail-safe mechanisms, hazard elimination. |

Defining Safety Management and Safety by Design

Safety Management involves systematic processes and policies aimed at minimizing risks and ensuring workplace safety through hazard identification, training, and compliance monitoring. Safety by Design integrates safety considerations directly into the design phase of products, systems, or facilities to proactively eliminate hazards and reduce risks before implementation. Both approaches contribute to overall safety, with Safety Management focusing on operational controls and Safety by Design emphasizing preventive measures embedded in the initial design.

Core Principles of Safety Management

Safety management prioritizes systematic hazard identification, risk assessment, and continuous monitoring to mitigate workplace incidents. Core principles include establishing a safety culture, active employee involvement, clear communication of safety policies, and leadership commitment. This structured approach ensures regulatory compliance, promotes accountability, and fosters ongoing improvement in safety performance.

Fundamentals of Safety by Design

Safety by Design fundamentally integrates hazard identification, risk assessment, and mitigation strategies directly into the development and engineering processes, ensuring potential safety issues are addressed at the source. This proactive approach contrasts with traditional Safety Management, which often reacts to incidents and relies on procedural controls and training to manage risks. Emphasizing safety from the design phase enhances overall system reliability, reduces long-term costs, and fosters a culture of prevention.

Key Differences Between Safety Management and Safety by Design

Safety Management emphasizes ongoing risk assessment, training, and compliance monitoring throughout a project's lifecycle, ensuring proactive hazard identification and mitigation. Safety by Design integrates hazard elimination and safety features directly into the engineering and architectural design phases, reducing risks before construction or operation begins. The key difference lies in Safety Management focusing on operational controls and behavioral strategies, while Safety by Design prioritizes embedding safety principles into the initial design to prevent hazards from arising.

Integration of Safety Management Systems (SMS)

Safety Management Systems (SMS) emphasize continuous monitoring, risk assessment, and procedural compliance to mitigate hazards, while Safety by Design integrates safety considerations directly into the engineering and development process. The integration of SMS with Safety by Design ensures proactive identification and control of risks, fostering a holistic safety culture within organizations. Combining these approaches enhances operational safety by embedding systematic risk management throughout both the design and implementation phases.

Proactive vs Reactive Safety Approaches

Safety Management emphasizes reactive strategies by addressing hazards after they occur, relying on training, policies, and incident response to minimize risks. Safety by Design incorporates proactive measures, integrating safety features into products and processes during the initial design phase to prevent accidents before they happen. Proactive safety approaches reduce incidents and enhance overall workplace safety, whereas reactive methods often lead to higher costs and operational disruptions due to unforeseen hazards.

Lifecycle Implementation of Safety by Design

Safety by Design integrates hazard identification, risk assessment, and control measures early in the product lifecycle, ensuring proactive mitigation of safety risks from concept through decommissioning. Lifecycle implementation involves continuous evaluation and adaptation of safety features to address emerging threats and regulatory changes, enhancing overall system resilience. This approach contrasts with traditional Safety Management, which often focuses on reactive measures and compliance during later operational stages rather than embedding safety within the initial design.

Regulatory and Industry Standards Comparison

Safety Management systems rely on compliance with regulatory frameworks such as OSHA, ISO 45001, and ANSI standards, emphasizing procedural controls and ongoing risk assessments. Safety by Design integrates safety considerations at the product development stage, aligning with industry standards like IEC 61508 for functional safety and ISO 13849 for machinery safety to reduce hazards inherently. Regulatory adherence in Safety Management often addresses operational risks, while Safety by Design targets hazard elimination through engineering controls, offering complementary approaches within comprehensive safety programs.

Measuring Effectiveness: Metrics and KPIs

Safety Management effectiveness is measured using metrics such as incident rates, near-miss reports, and compliance audit scores to track ongoing performance and identify areas for improvement. Safety by Design focuses on proactive KPIs like hazard elimination rates, design flaw detection frequency, and early risk mitigation success to ensure risks are minimized during the development phase. Combining both approaches through integrated dashboards enhances comprehensive safety performance evaluation across the project lifecycle.

Best Practices for Combining Both Approaches

Integrating Safety Management with Safety by Design enhances risk mitigation by embedding hazard identification early in the development process while maintaining continuous safety monitoring and improvement. Best practices include aligning design standards with organizational safety policies and fostering cross-functional collaboration between design engineers and safety managers. Utilizing data-driven safety analytics ensures proactive identification and resolution of potential safety issues throughout the product lifecycle.

Related Important Terms

Integrated Digital Safety (IDS)

Safety Management emphasizes procedural controls, risk assessments, and continuous monitoring to mitigate workplace hazards, while Safety by Design integrates hazard prevention directly into the engineering process. Integrated Digital Safety (IDS) enhances both approaches by leveraging digital twin technology, real-time data analytics, and automated safety protocols to create proactive, adaptive safety systems that reduce incidents and regulatory non-compliance.

Safety Lifecycle Management

Safety Management involves continuous monitoring, risk assessment, and compliance throughout the safety lifecycle to ensure operational safety. Safety by Design integrates hazard identification and mitigation early in product development, promoting proactive risk reduction across the safety lifecycle management process.

Proactive Hazard Engineering

Safety Management involves systematic procedures to identify, assess, and mitigate risks throughout an operational lifecycle, emphasizing compliance and incident response. Safety by Design integrates proactive hazard engineering during the initial design phase, embedding safety features to prevent hazards before they manifest, thereby enhancing overall system resilience and reducing reliance on reactive safety measures.

Embedded Safety Analytics

Embedded Safety Analytics enhances Safety Management by integrating real-time data monitoring and predictive insights directly into operational systems, enabling proactive hazard identification and risk mitigation. Safety by Design leverages these analytics during the development phase to embed safety protocols and compliance measures, reducing the likelihood of incidents from inception.

Human-Centric Design for Safety

Safety management prioritizes continuous monitoring, risk assessment, and procedural controls to mitigate hazards, while safety by design integrates human-centric principles early in the engineering process to inherently eliminate risks. Incorporating ergonomic interfaces, cognitive load considerations, and intuitive controls enhances system usability, reducing human error and promoting proactive safety culture.

Adaptive Safety Systems

Adaptive Safety Systems enhance Safety Management by integrating real-time data and predictive analytics to proactively identify and mitigate risks, improving response times and minimizing hazards. Safety by Design focuses on embedding safety features at the development stage, but Adaptive Safety Systems continuously evolve protection measures based on operational feedback and environmental changes.

AI-Driven Risk Mitigation

Safety Management leverages continuous monitoring and adaptive protocols powered by AI algorithms to identify and address risks in real-time, enhancing workplace hazard prevention. Safety by Design integrates AI-driven predictive analytics during the product development phase to proactively eliminate potential safety threats before deployment.

Fail-Safe Architecture Integration

Safety Management emphasizes protocols and training to reduce risks, while Safety by Design integrates Fail-Safe Architecture at the engineering level, ensuring systems inherently prevent or mitigate failures. Fail-Safe Architecture Integration uses redundancy, real-time monitoring, and automatic failover mechanisms to maintain operational safety and minimize hazards from system malfunctions.

Predictive Safety Modeling

Predictive Safety Modeling enhances Safety Management by using data-driven analysis to foresee and mitigate hazards, whereas Safety by Design integrates safety principles at the initial stages of product development to prevent risks proactively. Leveraging real-time data and advanced algorithms, Predictive Safety Modeling enables dynamic risk assessment, complementing Safety by Design's foundational approach to creating inherently safer systems.

Data-Informed Safety Culture

Safety Management relies on systematic risk assessments and incident data analysis to create protocols that minimize workplace hazards, whereas Safety by Design integrates hazard elimination directly into the engineering and architectural processes, ensuring safety is foundational. A Data-Informed Safety Culture leverages real-time safety metrics and predictive analytics to continuously improve both management systems and design methodologies, driving proactive hazard mitigation and fostering organizational accountability.

Safety Management vs Safety by Design Infographic

industrydif.com

industrydif.com