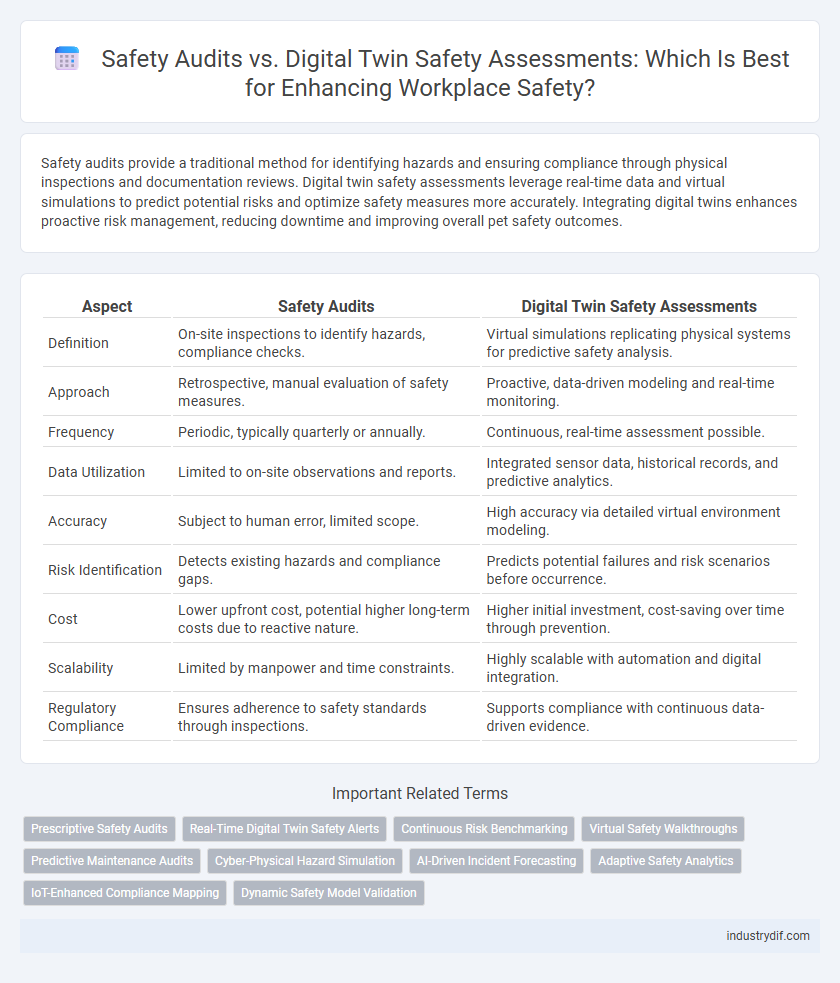

Safety audits provide a traditional method for identifying hazards and ensuring compliance through physical inspections and documentation reviews. Digital twin safety assessments leverage real-time data and virtual simulations to predict potential risks and optimize safety measures more accurately. Integrating digital twins enhances proactive risk management, reducing downtime and improving overall pet safety outcomes.

Table of Comparison

| Aspect | Safety Audits | Digital Twin Safety Assessments |

|---|---|---|

| Definition | On-site inspections to identify hazards, compliance checks. | Virtual simulations replicating physical systems for predictive safety analysis. |

| Approach | Retrospective, manual evaluation of safety measures. | Proactive, data-driven modeling and real-time monitoring. |

| Frequency | Periodic, typically quarterly or annually. | Continuous, real-time assessment possible. |

| Data Utilization | Limited to on-site observations and reports. | Integrated sensor data, historical records, and predictive analytics. |

| Accuracy | Subject to human error, limited scope. | High accuracy via detailed virtual environment modeling. |

| Risk Identification | Detects existing hazards and compliance gaps. | Predicts potential failures and risk scenarios before occurrence. |

| Cost | Lower upfront cost, potential higher long-term costs due to reactive nature. | Higher initial investment, cost-saving over time through prevention. |

| Scalability | Limited by manpower and time constraints. | Highly scalable with automation and digital integration. |

| Regulatory Compliance | Ensures adherence to safety standards through inspections. | Supports compliance with continuous data-driven evidence. |

Introduction to Safety Audits and Digital Twin Safety Assessments

Safety audits systematically evaluate workplace hazards and compliance with regulatory standards through on-site inspections, interviews, and document reviews. Digital twin safety assessments leverage real-time, virtual models of physical assets to simulate safety scenarios, identify potential risks, and optimize preventive measures dynamically. Both approaches enhance risk management but differ in their methodology, with audits relying on historical and observational data and digital twins providing predictive and continuous safety insights.

Core Principles of Safety Audits

Safety audits are structured evaluations designed to identify hazards, verify compliance with safety regulations, and assess the effectiveness of existing safety controls. These audits rely on systematic inspections, employee interviews, and documentation reviews to ensure workplace safety and risk mitigation. Core principles include objective evaluation, continuous improvement, and adherence to established safety standards.

Fundamentals of Digital Twin Safety Assessments

Digital Twin Safety Assessments leverage real-time data integration and simulation to predict potential hazards and optimize safety protocols more dynamically than traditional Safety Audits, which primarily rely on periodic inspections and static checklists. These assessments utilize virtual models mirroring physical systems, enabling continuous monitoring, risk analysis, and proactive mitigation strategies based on accurate, up-to-date information. By harnessing IoT sensors and advanced analytics, Digital Twin Safety Assessments enhance operational reliability and reduce incident rates through predictive insights and scenario-based evaluations.

Key Differences Between Safety Audits and Digital Twin Assessments

Safety audits primarily involve manual inspections and documentation reviews to identify compliance gaps and potential hazards based on current conditions, whereas digital twin safety assessments utilize advanced simulations of virtual replicas to predict and analyze safety risks dynamically in real-time operating environments. Safety audits focus on historical data and human observations, while digital twins integrate IoT sensors, AI analytics, and real-time data streaming to provide proactive risk mitigation strategies. This fundamental difference in approach allows digital twin assessments to offer continuous monitoring and scenario-based safety testing beyond the static scope of traditional safety audits.

Compliance and Regulatory Perspectives

Safety audits provide a structured evaluation of compliance with established safety regulations and standards, ensuring that organizations meet mandatory legal requirements. Digital twin safety assessments enable real-time monitoring and simulation of safety scenarios, offering predictive insights that enhance adherence to regulatory frameworks. Integrating digital twin technology in safety assessments improves the accuracy of compliance tracking and supports proactive risk management in line with evolving safety regulations.

Data Collection and Analysis Methods

Safety audits rely on manual data collection through inspections, checklists, and employee interviews, often resulting in periodic snapshots of workplace conditions. Digital twin safety assessments use real-time sensor data and advanced simulations to continuously monitor and analyze operational environments, enabling predictive hazard identification. The integration of IoT devices and AI algorithms in digital twins enhances data accuracy and provides dynamic risk evaluation beyond traditional audit capabilities.

Real-Time Monitoring vs Periodic Inspection

Safety audits rely on periodic inspections that provide snapshots of compliance and risk at specific intervals, potentially missing dynamic changes or emerging hazards. Digital twin safety assessments utilize real-time monitoring by simulating physical assets and processes, enabling continuous data collection and immediate identification of safety risks. This approach enhances proactive risk management, reducing incident response times and improving overall safety performance.

Accuracy and Predictive Capabilities

Safety audits rely on manual inspections and historical data, often limiting accuracy due to human error and incomplete information. Digital twin safety assessments leverage real-time data and simulations to provide higher accuracy in identifying potential hazards and predicting future risks. The predictive capabilities of digital twins enable proactive safety interventions, reducing incidents more effectively than traditional safety audits.

Implementation Challenges and Solutions

Safety audits often face challenges like limited real-time data and manual error susceptibility, hindering proactive risk identification. Digital twin safety assessments overcome these barriers by providing dynamic, real-time simulations of operational environments, enabling continuous monitoring and predictive hazard detection. Implementing digital twins requires overcoming integration complexities and data quality issues, which can be addressed through phased deployment strategies and robust data validation protocols.

Future Trends in Industrial Safety Assessments

Safety audits traditionally rely on scheduled inspections and manual data collection, providing snapshots of compliance and risk. Digital twin safety assessments leverage real-time data and simulation models to predict hazards and optimize safety protocols dynamically. Future trends indicate a shift towards integrated digital ecosystems where AI-driven digital twins enable continuous, proactive risk management in industrial environments.

Related Important Terms

Prescriptive Safety Audits

Prescriptive Safety Audits systematically identify hazards and enforce compliance by following established safety standards and protocols, ensuring consistent risk mitigation across industrial operations. Unlike Digital Twin Safety Assessments, which simulate scenarios using virtual models, prescriptive audits provide actionable, regulation-based recommendations verified through on-site inspections and empirical data.

Real-Time Digital Twin Safety Alerts

Real-time Digital Twin safety alerts enable continuous monitoring and instant identification of potential hazards, enhancing proactive risk mitigation beyond traditional Safety Audits' periodic evaluations. This dynamic approach leverages live data integration to simulate operational conditions, improving accuracy and responsiveness in safety management systems.

Continuous Risk Benchmarking

Safety audits provide periodic evaluations of workplace hazards, but digital twin safety assessments enable continuous risk benchmarking by creating real-time virtual replicas of physical environments. This dynamic approach improves hazard detection and predictive maintenance, enhancing proactive safety management and reducing incident rates.

Virtual Safety Walkthroughs

Virtual Safety Walkthroughs in digital twin safety assessments leverage real-time 3D models to identify hazards and evaluate compliance more efficiently than traditional safety audits. These immersive simulations enable proactive risk mitigation by visualizing potential safety issues before physical site inspections, enhancing accuracy and reducing downtime.

Predictive Maintenance Audits

Safety audits traditionally rely on retrospective data and manual inspections to identify hazards, whereas Digital Twin Safety Assessments integrate real-time sensor data and predictive analytics to forecast equipment failures and optimize maintenance schedules. Predictive maintenance audits using digital twins enhance safety by proactively identifying potential faults, reducing downtime, and preventing accidents through continuous monitoring and simulation.

Cyber-Physical Hazard Simulation

Safety audits provide traditional compliance checks but often lack the dynamic insight offered by digital twin safety assessments, which simulate cyber-physical hazards in real-time environments, enabling predictive hazard identification and mitigation. Digital twins integrate sensor data and virtual models to replicate system behaviors, enhancing hazard simulation accuracy and reducing risk through proactive safety management.

AI-Driven Incident Forecasting

AI-driven incident forecasting enhances safety audits and digital twin safety assessments by predicting potential hazards through real-time data analysis and machine learning algorithms. This technology enables proactive risk mitigation, improving workplace safety protocols and reducing accident rates with higher precision than traditional methods.

Adaptive Safety Analytics

Safety audits provide periodic, manual evaluations of workplace hazards, whereas digital twin safety assessments leverage real-time data and adaptive safety analytics to predict and mitigate risks dynamically. Adaptive safety analytics within digital twins continuously analyze environmental and operational data, enabling proactive and precise interventions that enhance overall safety performance.

IoT-Enhanced Compliance Mapping

IoT-enhanced compliance mapping in Safety Audits enables real-time monitoring and automated data collection, significantly improving accuracy and responsiveness compared to traditional methods. Digital Twin Safety Assessments leverage virtual replicas of physical assets to simulate hazard scenarios and predict risks, offering a proactive approach to identifying safety gaps and ensuring regulatory compliance.

Dynamic Safety Model Validation

Safety audits provide static evaluations based on historical data and compliance checklists, whereas Digital Twin Safety Assessments leverage real-time operational data to enable dynamic safety model validation, enhancing accuracy in hazard prediction and risk mitigation. Dynamic safety model validation through digital twins continuously updates safety parameters, reflecting real-world conditions for proactive decision-making and improved incident prevention.

Safety Audits vs Digital Twin Safety Assessments Infographic

industrydif.com

industrydif.com