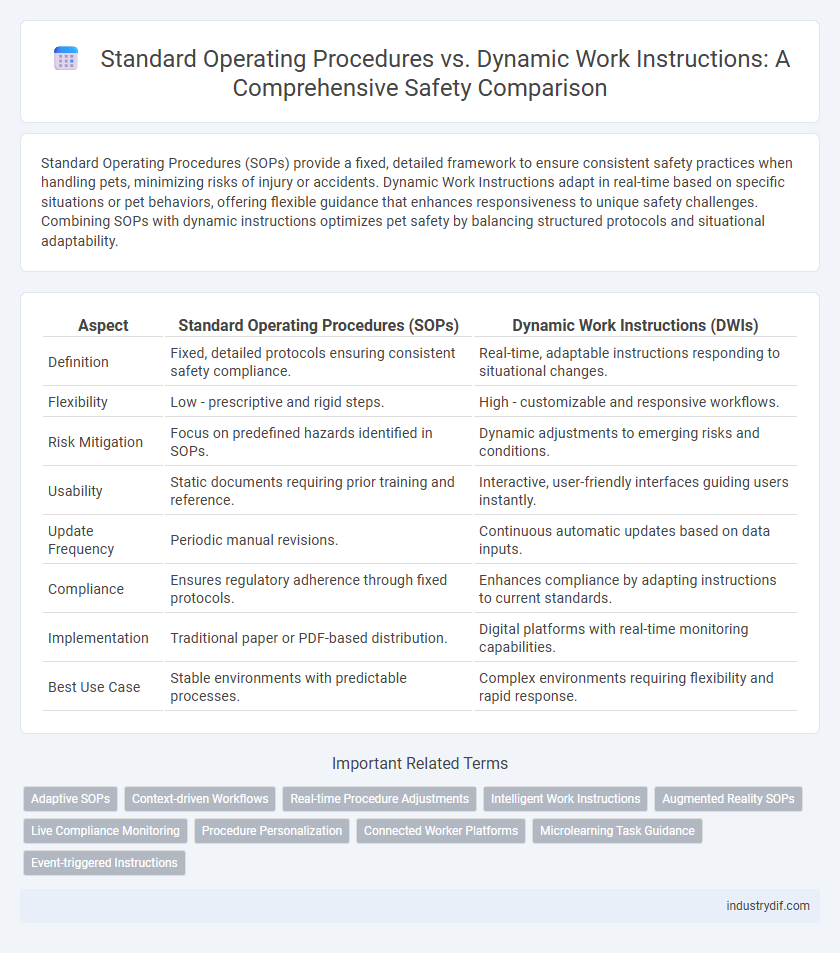

Standard Operating Procedures (SOPs) provide a fixed, detailed framework to ensure consistent safety practices when handling pets, minimizing risks of injury or accidents. Dynamic Work Instructions adapt in real-time based on specific situations or pet behaviors, offering flexible guidance that enhances responsiveness to unique safety challenges. Combining SOPs with dynamic instructions optimizes pet safety by balancing structured protocols and situational adaptability.

Table of Comparison

| Aspect | Standard Operating Procedures (SOPs) | Dynamic Work Instructions (DWIs) |

|---|---|---|

| Definition | Fixed, detailed protocols ensuring consistent safety compliance. | Real-time, adaptable instructions responding to situational changes. |

| Flexibility | Low - prescriptive and rigid steps. | High - customizable and responsive workflows. |

| Risk Mitigation | Focus on predefined hazards identified in SOPs. | Dynamic adjustments to emerging risks and conditions. |

| Usability | Static documents requiring prior training and reference. | Interactive, user-friendly interfaces guiding users instantly. |

| Update Frequency | Periodic manual revisions. | Continuous automatic updates based on data inputs. |

| Compliance | Ensures regulatory adherence through fixed protocols. | Enhances compliance by adapting instructions to current standards. |

| Implementation | Traditional paper or PDF-based distribution. | Digital platforms with real-time monitoring capabilities. |

| Best Use Case | Stable environments with predictable processes. | Complex environments requiring flexibility and rapid response. |

Understanding Standard Operating Procedures (SOPs)

Standard Operating Procedures (SOPs) provide detailed, consistent guidelines to ensure workplace safety and regulatory compliance by outlining specific tasks and responsibilities. SOPs are designed for routine activities to minimize risks, promote efficiency, and maintain quality control in hazardous environments. Clear, well-documented SOPs contribute to accident prevention and create a foundation for training, audits, and continuous safety improvements.

What Are Dynamic Work Instructions (DWIs)?

Dynamic Work Instructions (DWIs) are real-time, adaptable guidelines designed to improve workplace safety by providing precise, step-by-step instructions tailored to specific tasks or conditions. Unlike traditional Standard Operating Procedures (SOPs), DWIs use digital platforms to update and customize instructions instantly, reducing human error and enhancing compliance. This flexibility allows workers to respond effectively to changing environments, thereby minimizing safety risks and ensuring consistent operational performance.

Key Differences Between SOPs and DWIs

Standard Operating Procedures (SOPs) provide detailed, step-by-step instructions aimed at maintaining consistency and compliance in routine tasks, often emphasizing regulatory adherence. Dynamic Work Instructions (DWIs) are flexible, real-time guides tailored to specific conditions, incorporating visual aids and interactive elements to enhance worker adaptability and reduce human error. The key difference lies in SOPs' static nature for standardized operations versus DWIs' dynamic design for contextual, situational task execution.

Advantages of Standard Operating Procedures in Safety

Standard Operating Procedures (SOPs) provide consistent and clear guidelines that enhance workplace safety by reducing variability in task execution. Their structured format ensures comprehensive risk assessments and compliance with regulatory requirements, minimizing accidents and incidents. SOPs also facilitate training and accountability, leading to a safer work environment through standardized best practices.

Benefits of Dynamic Work Instructions for Workplace Safety

Dynamic Work Instructions significantly enhance workplace safety by providing real-time, context-sensitive guidance that adapts to changing conditions and specific tasks. Unlike static Standard Operating Procedures, these instructions reduce human error by delivering precise, step-by-step directions that account for situational variables and updated safety protocols. This flexibility improves compliance and enables faster response to hazards, resulting in a safer working environment.

When to Use SOPs vs DWIs in Safety Management

Standard Operating Procedures (SOPs) provide a structured framework for routine safety tasks requiring consistency and compliance, ensuring clear, repeatable processes critical in high-risk environments. Dynamic Work Instructions (DWIs) are ideal for variable or complex operations where real-time updates and adaptability enhance hazard recognition and immediate response. Safety management benefits from using SOPs for predictable workflows and DWIs during dynamic situations demanding flexibility and current information.

Impact of Digital Transformation on SOPs and DWIs

Digital transformation enhances Standard Operating Procedures (SOPs) and Dynamic Work Instructions (DWIs) by enabling real-time updates, improved accessibility, and increased accuracy in safety protocols. Interactive digital platforms facilitate instant dissemination of critical safety changes, reducing compliance risks and operational errors. Integration of AI and IoT technologies within SOPs and DWIs supports proactive hazard identification and adaptive safety management in dynamic work environments.

Common Challenges in Implementing SOPs and DWIs

Common challenges in implementing Standard Operating Procedures (SOPs) include rigidity that limits adaptability and difficulty keeping documents updated with process changes. Dynamic Work Instructions (DWIs) face obstacles such as integrating real-time data effectively and ensuring user-friendly interfaces for frontline employees. Both require ongoing training and technological support to maintain compliance and enhance workplace safety.

Regulatory Compliance: SOPs vs DWIs

Standard Operating Procedures (SOPs) ensure consistent regulatory compliance by providing fixed, detailed steps that align with industry standards and legal requirements. Dynamic Work Instructions (DWIs) enhance compliance adaptability, offering real-time updates and task-specific guidance to meet evolving safety regulations. Both SOPs and DWIs play crucial roles in maintaining safety standards, with SOPs providing foundational compliance and DWIs facilitating flexible, up-to-date adherence to regulatory changes.

Future Trends: Integrating SOPs and DWIs for Optimal Safety

Emerging safety protocols emphasize the integration of Standard Operating Procedures (SOPs) with Dynamic Work Instructions (DWIs) to enhance real-time adaptability and compliance. Leveraging digital platforms and AI-driven analytics, this fusion ensures precise guidance tailored to evolving work environments and risk scenarios. Organizations investing in interconnected SOP-DWI systems report significant reductions in workplace incidents and improved safety culture resilience.

Related Important Terms

Adaptive SOPs

Adaptive Standard Operating Procedures (SOPs) integrate real-time feedback and situational data, enhancing safety by allowing flexibility in response to changing work environments. Dynamic Work Instructions complement adaptive SOPs by providing step-by-step guidance tailored to specific tasks, ensuring consistent compliance and minimizing human errors in safety-critical operations.

Context-driven Workflows

Context-driven workflows in safety prioritize dynamic work instructions that adapt in real-time to specific conditions, enhancing worker responsiveness and reducing errors compared to static Standard Operating Procedures. These dynamic workflows integrate situational variables, ensuring instructions remain relevant and actionable under varying operational contexts.

Real-time Procedure Adjustments

Standard Operating Procedures (SOPs) offer fixed, documented safety protocols, while Dynamic Work Instructions enable real-time procedure adjustments to address evolving hazards and operational changes. Utilizing dynamic instructions enhances workplace safety by allowing immediate updates based on current risk assessments and situational awareness.

Intelligent Work Instructions

Intelligent Work Instructions leverage real-time data and adaptive technology to enhance safety by providing dynamic, context-specific guidance that surpasses traditional Standard Operating Procedures (SOPs) in flexibility and responsiveness. These advanced instructions minimize human error and improve compliance by continuously updating steps based on environmental conditions and worker feedback.

Augmented Reality SOPs

Augmented Reality (AR) Standard Operating Procedures enhance workplace safety by overlaying real-time, step-by-step guidance directly onto equipment, reducing human error compared to traditional SOPs. Dynamic Work Instructions delivered through AR adapt instantly to situational changes, ensuring precise compliance and immediate hazard recognition at critical points in operations.

Live Compliance Monitoring

Standard Operating Procedures (SOPs) provide fixed, detailed steps to ensure safety compliance, but Dynamic Work Instructions adapt in real-time to actual conditions, enhancing live compliance monitoring by instantly addressing deviations. Live compliance monitoring leverages dynamic instructions to reduce hazards and improve safety outcomes through continuous, context-sensitive guidance.

Procedure Personalization

Standard Operating Procedures (SOPs) offer a fixed framework ensuring compliance and consistency across safety protocols, while Dynamic Work Instructions provide real-time customization tailored to specific tasks and individual worker needs, enhancing procedure personalization. By integrating dynamic instructions, organizations can address variable operational environments, improve worker engagement, and reduce safety risks through task-specific guidance.

Connected Worker Platforms

Standard Operating Procedures (SOPs) provide consistent safety guidelines, while Dynamic Work Instructions on Connected Worker Platforms enable real-time updates and context-sensitive instructions, enhancing hazard awareness and compliance. Connected Worker Platforms integrate IoT data and worker feedback to adapt safety protocols instantly, reducing incidents and improving operational efficiency.

Microlearning Task Guidance

Standard Operating Procedures (SOPs) provide comprehensive, static safety guidelines, while Dynamic Work Instructions offer microlearning task guidance tailored to real-time conditions, enhancing worker compliance and reducing errors. Integrating task-specific microlearning in Dynamic Work Instructions increases retention and application of safety protocols compared to traditional SOPs.

Event-triggered Instructions

Event-triggered instructions enhance safety by providing real-time, context-specific guidance activated by specific conditions or incidents, ensuring immediate and precise responses. Unlike static standard operating procedures, these dynamic work instructions reduce the risk of errors during critical events by adapting to evolving situations and operational hazards.

Standard Operating Procedures vs Dynamic Work Instructions Infographic

industrydif.com

industrydif.com