Manual inspections for pet safety rely on scheduled physical checks, which can miss subtle changes or emerging risks between visits. Digital twin monitoring creates a real-time virtual replica of the pet's environment, enabling continuous observation and immediate detection of potential hazards. Integrating digital twins enhances accuracy and responsiveness, significantly improving overall pet safety management.

Table of Comparison

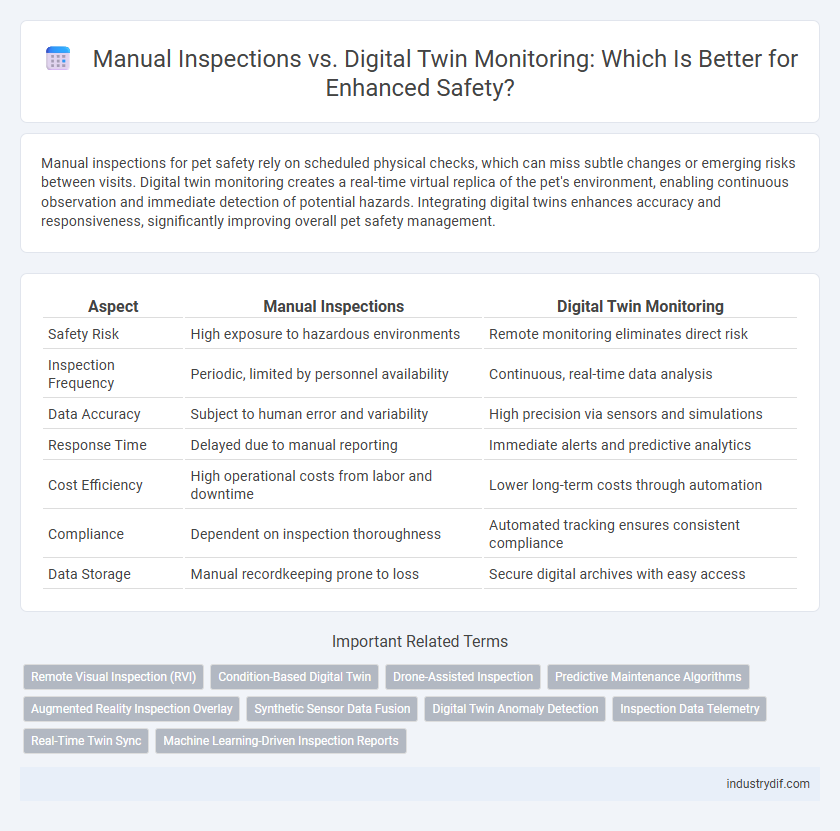

| Aspect | Manual Inspections | Digital Twin Monitoring |

|---|---|---|

| Safety Risk | High exposure to hazardous environments | Remote monitoring eliminates direct risk |

| Inspection Frequency | Periodic, limited by personnel availability | Continuous, real-time data analysis |

| Data Accuracy | Subject to human error and variability | High precision via sensors and simulations |

| Response Time | Delayed due to manual reporting | Immediate alerts and predictive analytics |

| Cost Efficiency | High operational costs from labor and downtime | Lower long-term costs through automation |

| Compliance | Dependent on inspection thoroughness | Automated tracking ensures consistent compliance |

| Data Storage | Manual recordkeeping prone to loss | Secure digital archives with easy access |

Overview of Safety in Industrial Environments

Manual inspections provide direct human oversight to identify safety hazards in industrial environments, but they can be time-consuming and prone to human error. Digital twin monitoring leverages real-time data and predictive analytics to enhance hazard detection and mitigate risks more efficiently. Integrating digital twins with traditional inspections improves overall safety by enabling continuous monitoring and timely responses to potential dangers.

Defining Manual Inspections in Safety Protocols

Manual inspections in safety protocols involve hands-on, physical examination of equipment, structures, or environments by trained personnel to identify potential hazards or non-compliance issues. These inspections rely on human observation and judgment to assess safety conditions, often documented through checklists and reports. While effective for detecting visible defects, manual inspections may miss subtle or real-time anomalies that continuous digital twin monitoring can capture.

Introduction to Digital Twin Monitoring for Safety

Digital Twin Monitoring revolutionizes safety by creating real-time, virtual replicas of physical assets, enabling continuous observation and predictive analysis to prevent hazards. Unlike manual inspections that rely on periodic human evaluation, digital twins deliver constant data integration from sensors, offering early detection of anomalies and reducing response time to potential risks. This advanced technology enhances safety protocols, minimizes downtime, and supports proactive maintenance by simulating scenarios and forecasting failures before they occur.

Key Differences Between Manual and Digital Twin Methods

Manual inspections rely heavily on human observation and periodic checks, often leading to potential delays and human error in identifying safety hazards. Digital Twin monitoring utilizes real-time data integration and predictive analytics to continuously assess conditions, enabling proactive hazard detection and enhanced decision-making. The key differences include accuracy, frequency of data updates, and the capacity for early anomaly identification, which significantly improve safety outcomes in digital twin systems.

Real-Time Hazard Detection with Digital Twins

Digital twin monitoring enables real-time hazard detection by continuously simulating and analyzing equipment and environmental conditions, surpassing the periodic limitations of manual inspections. Sensors integrated with digital twins collect live data, allowing instant identification of potential safety risks and facilitating proactive intervention. This continuous surveillance drastically reduces the likelihood of accidents and enhances overall workplace safety management.

Human Error in Manual Safety Inspections

Manual safety inspections are highly susceptible to human error due to factors such as fatigue, oversight, and inconsistent assessment standards. Digital twin monitoring leverages real-time data and predictive analytics to provide continuous, precise safety evaluations, minimizing the risk of missed hazards. Implementing digital twins enhances accuracy and reliability, significantly reducing incidents caused by manual inspection errors.

Data Accuracy: Manual Records vs Digital Analytics

Manual inspections rely heavily on human observation and handwritten records, which are prone to errors and inconsistencies, compromising data accuracy in safety assessments. Digital twin monitoring leverages real-time analytics and continuous sensor data, enhancing precision and enabling predictive maintenance through accurate digital replicas of physical assets. The integration of digital analytics significantly reduces data discrepancies, providing reliable insights for proactive safety management.

Cost Implications of Inspecting for Safety

Manual inspections for safety require significant labor costs and frequent downtime, increasing operational expenses and reducing productivity. Digital twin monitoring leverages real-time data and predictive analytics to minimize inspection intervals, lowering maintenance costs and preventing costly failures. Implementing digital twin technology enhances cost efficiency by reducing manual labor and enabling proactive safety management.

Regulatory Compliance and Reporting

Manual inspections rely heavily on human accuracy for regulatory compliance, often resulting in delayed reporting and potential oversight of critical safety issues. Digital twin monitoring enhances regulatory compliance by providing real-time data analytics and automated reporting, enabling proactive safety management and immediate adjustments to maintain standards. Regulatory agencies increasingly favor digital twin systems for their precision, comprehensive documentation, and audit-ready reporting capabilities that surpass traditional manual methods.

Future Trends in Industrial Safety Monitoring

Future trends in industrial safety monitoring highlight a shift from traditional manual inspections to advanced digital twin technologies, enabling continuous real-time risk assessment. Digital twins leverage IoT sensors and AI algorithms to simulate and predict hazardous scenarios, enhancing preventive measures and reducing human error. Integration of augmented reality with digital twin platforms will further empower safety personnel with immediate, data-driven insights for proactive hazard mitigation.

Related Important Terms

Remote Visual Inspection (RVI)

Remote Visual Inspection (RVI) leverages digital twin monitoring to enhance safety by enabling detailed, real-time assessments of equipment and infrastructure without physical presence, reducing the risk of accidents. Manual inspections, while traditional, expose personnel to hazardous environments and may miss subtle changes that continuous digital twin analytics can detect early, preventing costly failures.

Condition-Based Digital Twin

Condition-Based Digital Twin monitoring enhances safety by providing real-time, predictive analytics that identify equipment degradation before failures occur, reducing the reliance on periodic manual inspections prone to human error. This advanced digital approach enables continuous, precise condition assessment, minimizing downtime and mitigating risk through proactive maintenance interventions.

Drone-Assisted Inspection

Drone-assisted inspections enhance safety by enabling remote, precise manual inspections in hazardous environments without exposing personnel to risk. Integrating drones with digital twin monitoring provides real-time data, improving anomaly detection and proactive maintenance for safer operational conditions.

Predictive Maintenance Algorithms

Predictive maintenance algorithms integrated with digital twin monitoring enable real-time anomaly detection and proactive issue resolution, significantly reducing downtime and enhancing safety compared to traditional manual inspections. These algorithms analyze sensor data to forecast equipment failures, optimizing maintenance schedules and minimizing human error risks in critical operations.

Augmented Reality Inspection Overlay

Augmented reality inspection overlays enhance safety by providing real-time, visual guidance during manual inspections, reducing human error and improving hazard identification accuracy. Digital twin monitoring integrates this technology to simulate and predict system failures, enabling proactive maintenance and minimizing risk exposure.

Synthetic Sensor Data Fusion

Synthetic sensor data fusion in digital twin monitoring enhances safety by providing real-time, comprehensive insights that surpass the limitations of manual inspections. This integration allows continuous hazard detection and predictive maintenance, minimizing human error and improving response times in critical environments.

Digital Twin Anomaly Detection

Digital twin anomaly detection leverages real-time data and advanced algorithms to identify potential safety risks with higher precision compared to traditional manual inspections. This technology enables continuous monitoring, rapid issue detection, and predictive maintenance, significantly reducing downtime and enhancing overall workplace safety.

Inspection Data Telemetry

Digital twin monitoring enhances safety by providing real-time inspection data telemetry, enabling continuous condition tracking and rapid anomaly detection. Manual inspections rely on periodic data collection, which can lead to delayed responses and increased risk of undetected hazards.

Real-Time Twin Sync

Real-time twin sync in digital twin monitoring enables continuous, dynamic updates of asset conditions, drastically reducing the delays and human errors associated with manual inspections. This seamless synchronization ensures immediate identification of safety hazards and facilitates proactive intervention, enhancing overall operational safety and reliability.

Machine Learning-Driven Inspection Reports

Machine Learning-driven inspection reports enhance safety by enabling real-time anomaly detection and predictive maintenance through continuous data analysis from digital twins. These reports provide precise, actionable insights that surpass the limitations of manual inspections by reducing human error and accelerating decision-making processes.

Manual Inspections vs Digital Twin Monitoring Infographic

industrydif.com

industrydif.com