Centrifuges use rapid spinning to separate particles based on density, making them ideal for isolating cellular components or blood fractions in scientific research. Acoustic levitation, on the other hand, employs ultrasonic waves to suspend and manipulate small samples without physical contact, preserving delicate structures during experiments. Both techniques enhance precision and control but cater to different experimental requirements in scientific pet studies.

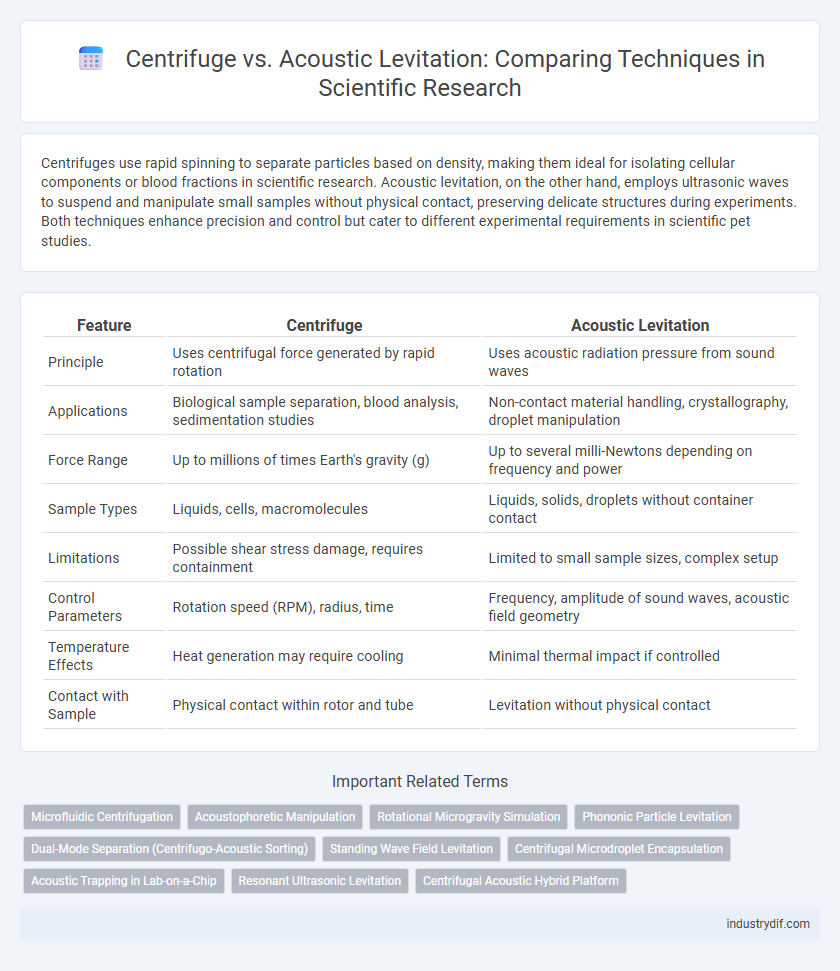

Table of Comparison

| Feature | Centrifuge | Acoustic Levitation |

|---|---|---|

| Principle | Uses centrifugal force generated by rapid rotation | Uses acoustic radiation pressure from sound waves |

| Applications | Biological sample separation, blood analysis, sedimentation studies | Non-contact material handling, crystallography, droplet manipulation |

| Force Range | Up to millions of times Earth's gravity (g) | Up to several milli-Newtons depending on frequency and power |

| Sample Types | Liquids, cells, macromolecules | Liquids, solids, droplets without container contact |

| Limitations | Possible shear stress damage, requires containment | Limited to small sample sizes, complex setup |

| Control Parameters | Rotation speed (RPM), radius, time | Frequency, amplitude of sound waves, acoustic field geometry |

| Temperature Effects | Heat generation may require cooling | Minimal thermal impact if controlled |

| Contact with Sample | Physical contact within rotor and tube | Levitation without physical contact |

Introduction to Scientific Separation Techniques

Centrifuge and acoustic levitation are advanced scientific separation techniques used to isolate substances based on distinct physical properties. Centrifuges separate components by applying high-speed rotational forces to exploit differences in density, widely used in biochemistry and clinical laboratories. Acoustic levitation uses sound waves to suspend and manipulate small particles or droplets without contact, offering contamination-free separation ideal for delicate materials.

Understanding Centrifuge Technology

Centrifuge technology utilizes high-speed rotation to generate centrifugal force, enabling the separation of particles based on density differences within a mixture. This method is essential in scientific fields such as biochemistry and molecular biology for isolating cells, organelles, and macromolecules. Compared to acoustic levitation, which suspends particles using sound waves, centrifugation offers precise control over separation parameters and is widely applied in clinical diagnostics and research laboratories.

Fundamentals of Acoustic Levitation

Acoustic levitation utilizes intense ultrasonic waves to create standing wave patterns, generating pressure nodes that counteract gravitational forces on small objects or droplets. The fundamental principle involves manipulating sound pressure to suspend particles in mid-air without physical contact, enabling precise handling in contamination-sensitive environments. Unlike centrifuges that rely on rotational inertia and centrifugal force to separate components by density, acoustic levitation offers non-contact positioning through acoustic radiation forces derived from wave interference and pressure gradients.

Key Principles: Centrifugal Force vs Acoustic Pressure

Centrifuge technology operates on the principle of centrifugal force, which separates particles based on density by spinning samples at high speeds, generating a force that pushes denser materials outward. Acoustic levitation, however, utilizes acoustic pressure generated by ultrasonic standing waves to suspend and manipulate small objects in mid-air without physical contact. The fundamental difference lies in mechanical force application versus the use of sound wave pressure to achieve particle separation or positioning.

Applications in Laboratory and Industrial Settings

Centrifuges are widely used in laboratory and industrial settings for separating substances based on density differences, enabling applications such as blood component separation, nanoparticle isolation, and wastewater treatment. Acoustic levitation offers non-contact manipulation of small particles or droplets, valuable in pharmaceutical crystallization, material synthesis, and contamination-free sample handling. Both technologies enhance precision and efficiency in processes requiring separation or suspension without physical containment.

Sample Handling and Sensitivity Comparison

Centrifuge techniques excel in sample separation through high-speed rotational forces, offering robust handling of heterogeneous mixtures with minimal sample loss. Acoustic levitation allows contactless manipulation, preserving sample integrity and enabling enhanced sensitivity by reducing contamination and adsorption artifacts. Sensitivity in acoustic levitation surpasses centrifugation in detecting delicate biomolecules due to its non-invasive nature, though centrifuges provide superior throughput for bulk sample processing.

Advantages and Limitations of Centrifuges

Centrifuges offer precise separation of substances based on density differences, enabling rapid isolation of cellular components, proteins, and nucleic acids critical in scientific research. They provide scalability and high-throughput processing but are limited by potential sample damage due to high g-forces and are less effective for manipulating delicate or airborne samples. Unlike acoustic levitation, which enables contactless handling of fragile materials, centrifuges require physical containment and may induce shear stress in sensitive biological specimens.

Benefits and Challenges of Acoustic Levitation

Acoustic levitation offers contactless manipulation of small particles and liquids, minimizing contamination and mechanical damage compared to centrifuges, which rely on high-speed rotation and physical separation. It enables precise control in microgravity simulations and delicate material studies, but challenges include limited payload capacity and sensitivity to environmental vibrations. Scaling acoustic levitation for industrial or larger-scale applications remains a significant technical hurdle.

Emerging Trends in Material Manipulation

Emerging trends in material manipulation highlight the growing integration of acoustic levitation with centrifuge techniques, enabling precise control over particle positioning and manipulation without physical contact. Acoustic levitation offers enhanced capabilities in handling delicate and reactive materials by using sound waves to suspend particles, while centrifuges provide rapid separation based on density differences under high rotational forces. Combining these technologies facilitates innovative applications in pharmaceuticals, material science, and biochemical assays, promoting contamination-free processing and improved nanoscale material assembly.

Future Prospects: Integrating Centrifuge and Acoustic Technologies

Integrating centrifuge and acoustic levitation technologies presents promising future prospects for enhancing material manipulation and biological research under simulated microgravity conditions. Combining high-precision control of centrifugal forces with the non-contact handling capabilities of acoustic levitation can enable novel experimental setups for drug development, cell culture, and tissue engineering. Advancements in real-time modulation of acoustic fields synchronized with variable centrifuge speeds may lead to unprecedented control over particle positioning and force application in microgravity analog experiments.

Related Important Terms

Microfluidic Centrifugation

Microfluidic centrifugation enables precise manipulation of fluids at microscale by harnessing centrifugal forces, offering high throughput separation with minimal sample volumes compared to acoustic levitation, which relies on ultrasonic waves for contactless particle handling. This centrifugal approach enhances efficiency in bio-sample processing and cell sorting by integrating controlled rotational speeds within microfluidic channels.

Acoustophoretic Manipulation

Acoustophoretic manipulation utilizes acoustic levitation to precisely control particles in fluid mediums by generating standing sound waves that exert forces on suspended objects, enabling non-invasive separation and positioning with high spatial resolution. Unlike centrifuges, which rely on gravitational force and rotational speed to separate components based on density, acoustic levitation offers contactless handling, crucial for delicate biological samples and microscale applications.

Rotational Microgravity Simulation

Centrifuge technology generates rotational microgravity by creating artificial gravity gradients through high-speed spinning, enabling precise simulation of gravity levels for extended biological and physical experiments. Acoustic levitation, while effective in suspending small particles using sound waves, lacks the capability to replicate consistent rotational microgravity environments required for long-duration microgravity studies.

Phononic Particle Levitation

Phononic particle levitation leverages precisely engineered acoustic waves to trap particles in mid-air using phononic crystals, offering contactless manipulation with high spatial resolution compared to traditional centrifuge techniques that rely on rotational forces for particle separation. This acoustic method provides enhanced control over particle positioning and reduced mechanical stress, making it ideal for delicate scientific applications such as material synthesis and biological sample handling.

Dual-Mode Separation (Centrifugo-Acoustic Sorting)

Dual-mode separation combining centrifuge and acoustic levitation leverages centrifugal force for bulk sedimentation alongside precise, contactless particle manipulation via ultrasonic standing waves, enhancing sorting efficiency and selectivity at micro- to nanoscale levels. This integrated centrifugo-acoustic sorting technique optimizes separation performance by enabling simultaneous density-based fractionation and acoustic contrast-based discrimination within heterogeneous mixtures.

Standing Wave Field Levitation

Standing wave field levitation in acoustic levitation generates stable nodes that trap particles with minimal mechanical stress, enabling precise manipulation of delicate biological samples. Unlike centrifuges, which rely on high rotational forces to separate components based on density, standing wave acoustic levitation offers contactless handling without the shear forces that can damage sensitive materials.

Centrifugal Microdroplet Encapsulation

Centrifugal microdroplet encapsulation leverages high-speed rotational forces to generate uniform microdroplets with precise size control, enhancing encapsulation efficiency compared to acoustic levitation, which relies on ultrasonic waves to suspend droplets without direct contact. This technique provides superior scalability and throughput for applications in drug delivery, cell encapsulation, and biochemical assays by enabling continuous production of monodisperse droplets under controlled centrifugal fields.

Acoustic Trapping in Lab-on-a-Chip

Acoustic levitation enables precise, contact-free manipulation of microdroplets within lab-on-a-chip devices by generating standing sound waves that trap particles at pressure nodes, enhancing sensitivity and control in biochemical assays. Unlike centrifugation, acoustic trapping minimizes mechanical stress and allows for real-time, label-free analysis of cells and biomolecules in microscale environments.

Resonant Ultrasonic Levitation

Resonant ultrasonic levitation uses high-frequency acoustic waves to create stable nodes that counteract gravity, enabling contactless manipulation of small particles or liquids with minimal contamination risk. Compared to centrifuges, which rely on rotational force to separate substances based on density, resonant ultrasonic levitation offers precision in handling delicate or reactive materials without inducing shear stress.

Centrifugal Acoustic Hybrid Platform

The Centrifugal Acoustic Hybrid Platform integrates centrifugal force with acoustic levitation to enhance particle manipulation precision and stability in microgravity environments. This hybrid approach enables efficient separation and non-contact handling of micro- and nanoparticles, optimizing experimental workflows in material science and biological research.

Centrifuge vs Acoustic Levitation Infographic

industrydif.com

industrydif.com