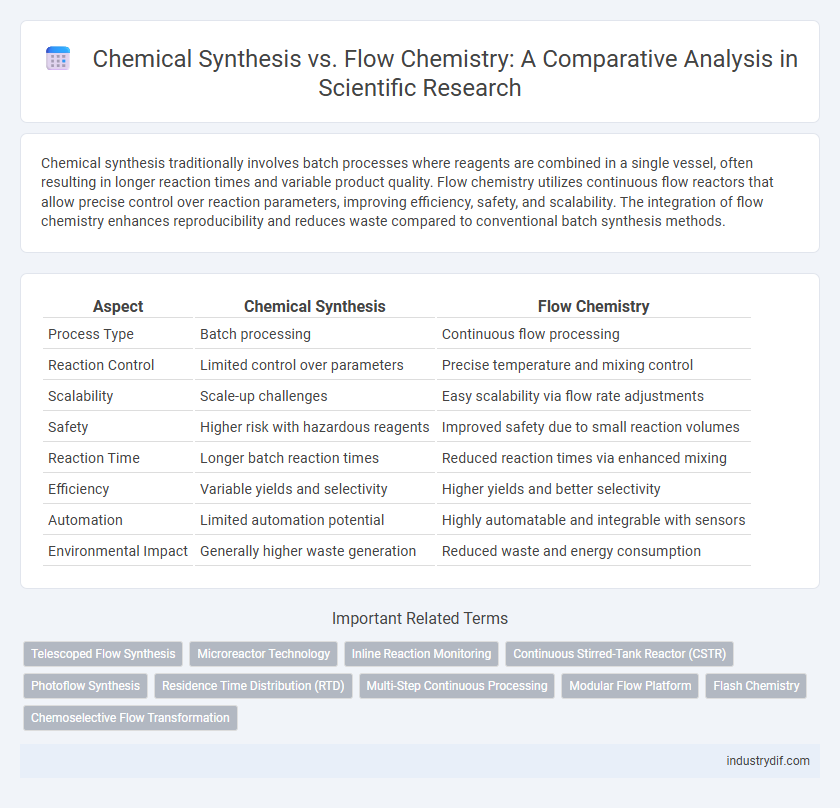

Chemical synthesis traditionally involves batch processes where reagents are combined in a single vessel, often resulting in longer reaction times and variable product quality. Flow chemistry utilizes continuous flow reactors that allow precise control over reaction parameters, improving efficiency, safety, and scalability. The integration of flow chemistry enhances reproducibility and reduces waste compared to conventional batch synthesis methods.

Table of Comparison

| Aspect | Chemical Synthesis | Flow Chemistry |

|---|---|---|

| Process Type | Batch processing | Continuous flow processing |

| Reaction Control | Limited control over parameters | Precise temperature and mixing control |

| Scalability | Scale-up challenges | Easy scalability via flow rate adjustments |

| Safety | Higher risk with hazardous reagents | Improved safety due to small reaction volumes |

| Reaction Time | Longer batch reaction times | Reduced reaction times via enhanced mixing |

| Efficiency | Variable yields and selectivity | Higher yields and better selectivity |

| Automation | Limited automation potential | Highly automatable and integrable with sensors |

| Environmental Impact | Generally higher waste generation | Reduced waste and energy consumption |

Overview of Chemical Synthesis

Chemical synthesis involves the stepwise construction of complex molecules from simpler substances through a series of chemical reactions, often conducted in batch processes. This traditional method allows precise control over reaction conditions such as temperature, pressure, and reagent concentration, which is essential for optimizing yield and selectivity. Laboratory-scale chemical synthesis is fundamental for producing pharmaceuticals, agrochemicals, and specialty materials, though it may face limitations in scalability and process efficiency compared to continuous flow chemistry.

Fundamentals of Flow Chemistry

Flow chemistry relies on continuous movement of reactants through a reactor, enabling precise control over reaction parameters such as temperature, pressure, and reaction time, which enhances reproducibility and scalability compared to traditional batch chemical synthesis. Microreactors in flow chemistry facilitate efficient heat and mass transfer, reducing side reactions and improving yield. The fundamental advantage of flow chemistry lies in its ability to perform highly controlled, continuous reactions that optimize safety and efficiency in chemical synthesis.

Comparative Analysis: Batch vs Flow Processes

Batch chemical synthesis involves discrete reaction steps conducted in individual vessels, allowing precise control over reaction parameters but often leading to longer processing times and scalability challenges. Flow chemistry, by contrast, utilizes continuous reactors enabling enhanced heat and mass transfer, improved reaction control, and greater scalability for industrial applications. Comparative analysis reveals that flow processes offer superior efficiency, safety, and reproducibility compared to traditional batch methods.

Reaction Efficiency and Yield

Chemical synthesis in batch processes often faces challenges in reaction efficiency and yield due to limited mass and heat transfer, leading to longer reaction times and potential side reactions. Flow chemistry enhances reaction efficiency by providing continuous mixing and precise control over reaction parameters, resulting in higher yields and improved reproducibility. The superior heat dissipation and scalable nature of flow reactors minimize byproduct formation, optimizing overall synthetic productivity.

Scalability in Chemical Production

Flow chemistry offers superior scalability in chemical production compared to traditional batch chemical synthesis by enabling continuous processing and precise control over reaction parameters, which enhances reproducibility and reduces reaction times. The continuous nature of flow reactors allows for seamless scale-up from lab to industrial scale without significant changes in reaction conditions or yield. In contrast, batch synthesis often encounters challenges in maintaining consistent product quality and efficiency when transitioning from small-scale laboratory settings to large-scale manufacturing.

Safety Considerations in Synthesis Methods

Flow chemistry enhances safety in chemical synthesis by minimizing the volume of reactive intermediates at any given time, reducing the risk of hazardous exposure and uncontrolled reactions. Traditional batch chemical synthesis often involves larger quantities of reactants, increasing the potential for spills, explosions, and toxic emissions. Process intensification in flow reactors enables precise temperature and pressure control, mitigating thermal runaways and improving overall operational safety.

Environmental Impact and Sustainability

Chemical synthesis traditionally relies on batch processes that often generate significant waste and consume large amounts of energy, contributing to environmental degradation. Flow chemistry enhances sustainability by enabling continuous reactions with better heat and mass transfer, reducing reagent use, and minimizing hazardous by-products. The adoption of flow chemistry aligns with green chemistry principles by improving atom economy and lowering the carbon footprint of chemical manufacturing.

Automation and Process Control in Chemistry

Flow chemistry enhances automation and process control by enabling continuous reagent mixing and real-time monitoring, which significantly improves reaction precision and reproducibility compared to traditional batch chemical synthesis. Automated flow systems integrate advanced sensors and feedback loops, allowing dynamic adjustment of reaction parameters such as temperature, pressure, and flow rate for optimal yield and safety. This level of control reduces human error, minimizes waste, and accelerates scale-up from laboratory to industrial production.

Applications in Pharmaceutical Manufacturing

Chemical synthesis remains fundamental in pharmaceutical manufacturing, enabling the production of complex molecular structures with precise stereochemistry critical for drug efficacy. Flow chemistry enhances this process by offering continuous reaction monitoring, improved safety, and scalability, which accelerates drug development and reduces manufacturing costs. Integration of flow chemistry in pharmaceutical synthesis allows for rapid optimization of reaction conditions and seamless scale-up from laboratory to production scale.

Future Trends in Chemical Synthesis Technologies

Future trends in chemical synthesis technologies emphasize the increasing adoption of flow chemistry due to its enhanced control over reaction parameters, improved safety, and scalability. Innovations in microreactor design and inline analytical techniques are driving more efficient, sustainable, and precise synthetic pathways compared to traditional batch chemical synthesis. Integration of artificial intelligence and machine learning in flow chemistry systems is poised to accelerate reaction optimization and discovery processes.

Related Important Terms

Telescoped Flow Synthesis

Telescoped flow synthesis integrates multiple reaction steps into a continuous flow system, significantly enhancing reaction efficiency and minimizing intermediate purification compared to traditional batch chemical synthesis. This approach improves scalability, reduces waste, and offers precise control over reaction parameters, making it a preferred method for complex molecule production in pharmaceutical and fine chemical industries.

Microreactor Technology

Microreactor technology enhances chemical synthesis by enabling precise control of reaction conditions within microscale channels, leading to improved heat and mass transfer efficiency. This approach contrasts with traditional batch flow chemistry, offering faster reaction rates, higher selectivity, and safer handling of hazardous materials in continuous manufacturing processes.

Inline Reaction Monitoring

Inline reaction monitoring in flow chemistry enables real-time data acquisition and precise control of reaction parameters, significantly enhancing chemical synthesis efficiency and product consistency. This approach reduces reaction times and minimizes waste by continuously analyzing reaction progress through spectroscopic or chromatographic techniques integrated directly into the flow system.

Continuous Stirred-Tank Reactor (CSTR)

Continuous Stirred-Tank Reactors (CSTRs) enable precise control over reaction conditions in flow chemistry, enhancing scalability and reproducibility compared to traditional batch chemical synthesis. The continuous operation in CSTRs improves heat and mass transfer efficiency, leading to higher product yields and consistent quality in chemical manufacturing.

Photoflow Synthesis

Photoflow synthesis integrates continuous flow chemistry with photochemical reactions, offering enhanced control over light exposure and reaction parameters compared to traditional batch chemical synthesis. This method improves reaction efficiency, scalability, and safety by enabling precise photon flux management and reducing reaction times, making it ideal for complex organic transformations.

Residence Time Distribution (RTD)

Residence Time Distribution (RTD) in chemical synthesis significantly influences product consistency and reaction efficiency, with flow chemistry offering narrower RTD due to continuous and controlled reactant movement compared to batch processes. Precise RTD control in flow reactors minimizes by-products and optimizes reaction kinetics, enhancing scalability and reproducibility in industrial applications.

Multi-Step Continuous Processing

Multi-step continuous processing in flow chemistry enhances chemical synthesis by enabling precise control over reaction conditions, improving yield, and reducing reaction times compared to traditional batch methods. This approach facilitates seamless integration of sequential reactions, minimizes intermediate handling, and supports scalable production of complex molecules with increased safety and efficiency.

Modular Flow Platform

Modular flow platforms enhance chemical synthesis by enabling continuous, scalable reactions with precise control over reaction parameters, improving yield and reproducibility compared to traditional batch methods. Integration of customizable modules for mixing, heating, and separation streamlines multistep synthesis, reducing reaction times and waste generation in flow chemistry applications.

Flash Chemistry

Flash chemistry offers rapid reaction times and precise control over transient intermediates, enhancing yield and selectivity compared to traditional batch chemical synthesis. By integrating microreactor technology, flash chemistry minimizes side reactions and thermal degradation, enabling scalable and efficient production of complex molecules.

Chemoselective Flow Transformation

Chemoselective flow transformation in flow chemistry enables precise control over reaction conditions, enhancing selectivity and yield compared to traditional batch chemical synthesis methods. Continuous flow reactors facilitate rapid mixing and heat transfer, reducing side reactions and allowing for efficient scale-up of complex chemoselective reactions.

Chemical Synthesis vs Flow Chemistry Infographic

industrydif.com

industrydif.com